Method for separating and extracting cannabidiol from industrial cannabis plants

A technology of industrial hemp and cannabidiol, applied in the field of natural medicinal chemistry, can solve the problems of difficulty in accurately controlling the polarity change of the eluent, complicated operation, etc., and achieve the effects of short cycle, simple operation and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

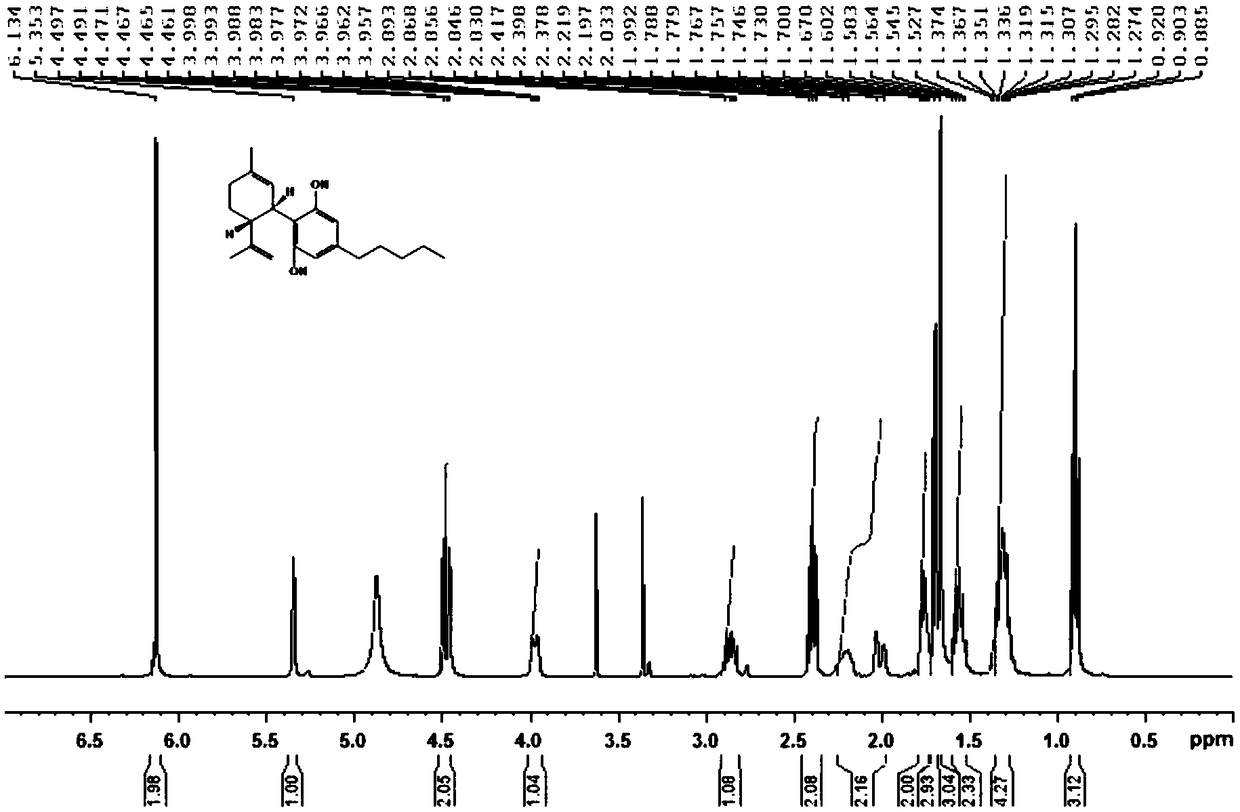

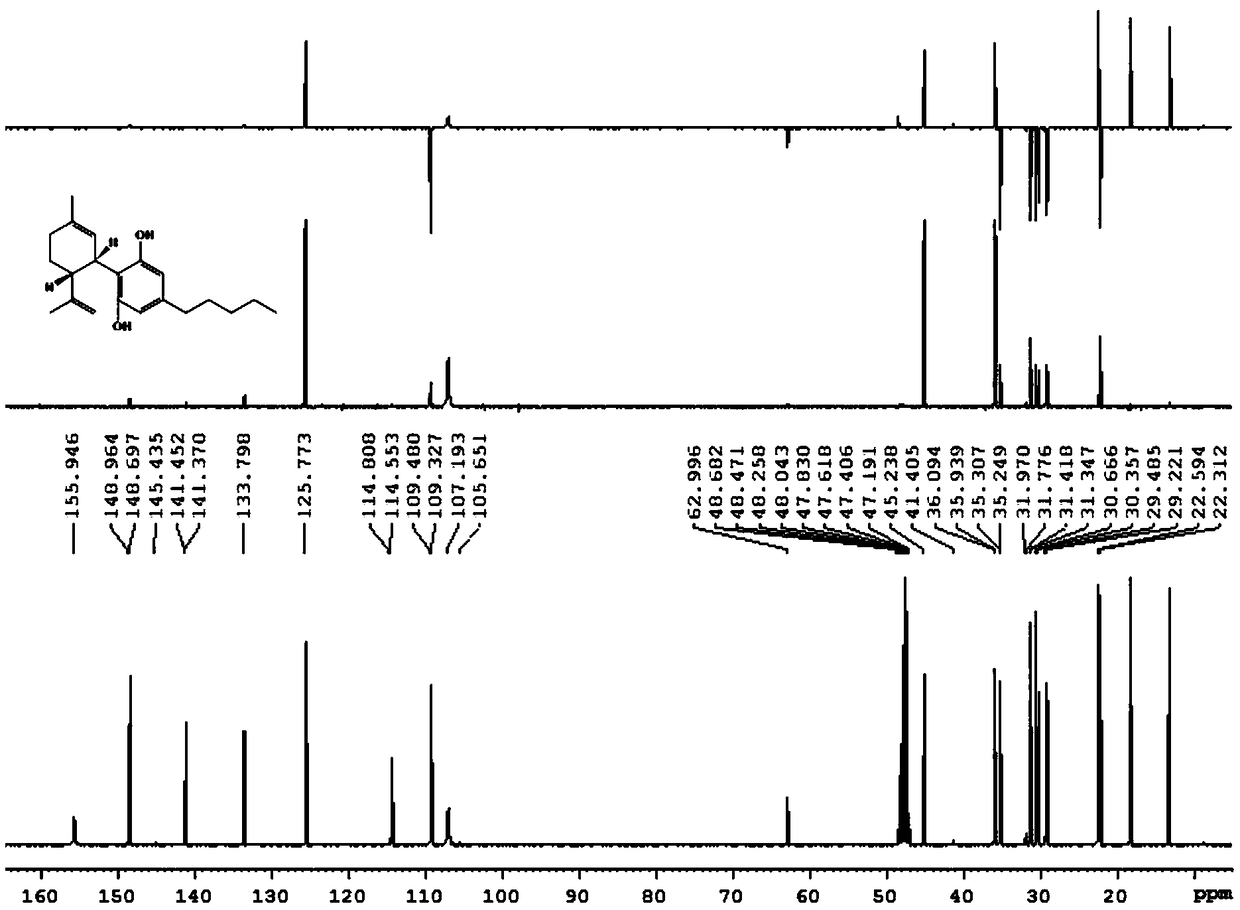

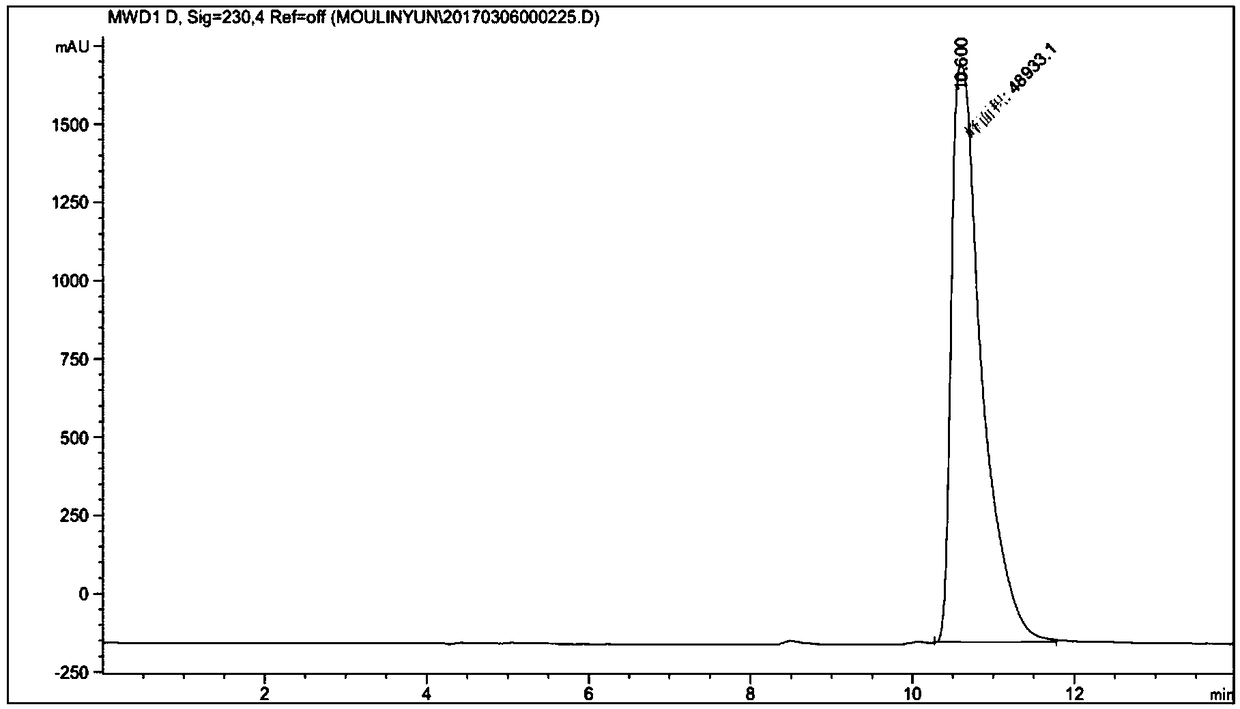

Image

Examples

Embodiment 1

[0043] Follow the steps below to isolate and extract cannabidiol from industrial hemp plants:

[0044] 1.1 Plant extraction and concentration

[0045] Take by weighing 3700g the industrial hemp (moisture<5wt%) that contains stem, leaf and seed, pulverize through pulverizer, sample powder crosses 80 mesh sieves and sieves, the industrial hemp sample powder with the 95% ethanol / water solution of weight ratio 2 times amount Soaking, ultrasonic hot-dipping extraction, water bath temperature 47°C, ultrasonic power 200W, a total of 4 extractions, 8 hours each time; filter, combine extracts, water bath decompression concentration to evaporate ethanol / water solution, water bath temperature 55°C, vacuum pressure 0.07MPa, obtain 550g sample extract a.

[0046] 1.2 Extraction

[0047]The 550g sample extract a obtained in the above step 1.1 is fully stirred with purified water with a weight ratio of 1 times to a suspension state, and then the suspended sample liquid is extracted with pe...

Embodiment 2

[0054] Follow the steps below to isolate and extract cannabidiol from industrial hemp plants:

[0055] 1.1 Plant extraction and concentration

[0056] Weigh 3700g of industrial hemp containing stems, leaves and seeds (moisture<5wt%), pulverize through a pulverizer, and sieve the sample powder through an 80-mesh sieve, soak the industrial hemp sample powder with 95% aqueous ethanol solution with a weight ratio of 2.5 times , ultrasonic hot dip extraction, water bath temperature 50°C, ultrasonic power 275W, a total of 5 extractions, 8 hours each time; filter and combine the extracts, water bath decompression concentration to evaporate ethanol aqueous solution, water bath temperature 53°C, vacuum pressure 0.08 MPa, obtain 554g sample extract a.

[0057] 1.2 Extraction

[0058] The 554g sample extract a obtained in the above step 1.1 is fully stirred with purified water of 1.5 times the weight ratio until suspended, and then the suspended sample liquid is extracted with petroleu...

Embodiment 3

[0065] Follow the steps below to isolate and extract cannabidiol from industrial hemp plants:

[0066] 1.1 Plant extraction and concentration

[0067] Take by weighing 3700g the industrial hemp (moisture<5wt%) that contains stem, leaf and seed, pulverize through pulverizer, sample powder is sieved through 80 mesh sieves, industrial hemp sample powder is 95% ethanol / water solution with weight ratio 3 times amount Soaking, ultrasonic hot-dip extraction, water bath temperature 53°C, ultrasonic power 300W, a total of 6 extractions, 8 hours each time; filter, combine extracts, water bath decompression concentration to evaporate ethanol / water solution, water bath temperature 58°C, vacuum pressure It is 0.06MPa, obtains 558g sample extract a.

[0068] 1.2 Extraction

[0069] The 558g sample extract a obtained in the above step 1.1 is fully stirred with purified water with a weight ratio of 2 times to a suspended state, and then the suspended sample liquid is extracted with petroleu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com