Simple method for synthesizing cedrol glucoside

A technology of glucoside and synthesis method, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc. It can solve the problems of restricting the industrial production of products, complicated purification methods, and affecting manufacturing costs, etc., and achieves convenient operation and simple process , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment synthesizes cedaryl alcohol glucoside according to the following steps:

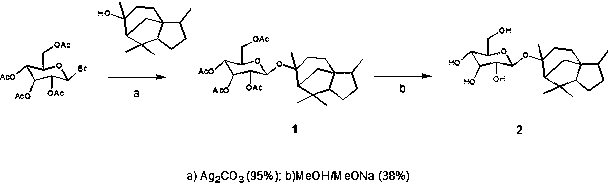

[0029] Step 1: Synthesis of Crude Cedaryl Alcohol Tetraacetylglucoside (Compound 1)

[0030] Add 22.2g cedaryl alcohol, 41.1g bromotetraacetylglucose, 3g 4A molecular sieves, 27.6g silver carbonate, 100mL dichloromethane into a 250mL three-neck round bottom flask, stir at room temperature for 2h, after the reaction is over, filter to remove the solid, and the filtrate is passed through Concentration obtained 53.5 g of cedaryl alcohol tetraacetyl glucoside crude product, yield 96.9%.

[0031] Step 2: Synthesis of cederyl alcohol glucoside (compound 2)

[0032] Dissolve 53.5 g of cedarwood alcohol tetraacetyl glucoside crude product obtained in step 1 in 400 mL of methanol, add 1 mL of methanol solution of sodium methoxide, stir at room temperature, after the reaction, adjust the pH of the solution to neutral with cation exchange resin, add activated carbon Stir at 50°C for ...

Embodiment 2

[0034] The present embodiment synthesizes cedaryl alcohol glucoside according to the following steps:

[0035] Step 1: Synthesis of Crude Cedaryl Alcohol Tetraacetylglucoside (Compound 1)

[0036] Add 44.4g cedarwood alcohol, 84g bromotetraacetylglucose, 8g 4A molecular sieve, 55.2g silver carbonate, 250mL dichloromethane into a 500mL three-neck round bottom flask, stir at room temperature for 2h, after the reaction is over, filter to remove the solid, and the filtrate is concentrated Obtain 110 g of cedaryl alcohol tetraacetyl glucoside crude product, yield 98%.

[0037] Step 2: Synthesis of cederyl alcohol glucoside (compound 2)

[0038] Dissolve 110g of cedarwood alcohol tetraacetylglucoside crude product obtained in step 1 in 800mL of methanol, add 3mL of methanol solution of sodium methoxide, and stir at room temperature. Stir at 50°C for 45 minutes to decolorize, after filtration, concentrate the filtrate to remove the solvent, wash the remaining solid with 3×50mL ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com