a high quality c 2 the se (1-x) a x crystal growth method

A growth method and high-quality technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as difficult analysis of high thermoelectric performance mechanism of materials, difficulties in practical application development, etc., to achieve simple and effective crystal growth methods, The device is simple and easy to operate, and the delivery agent is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

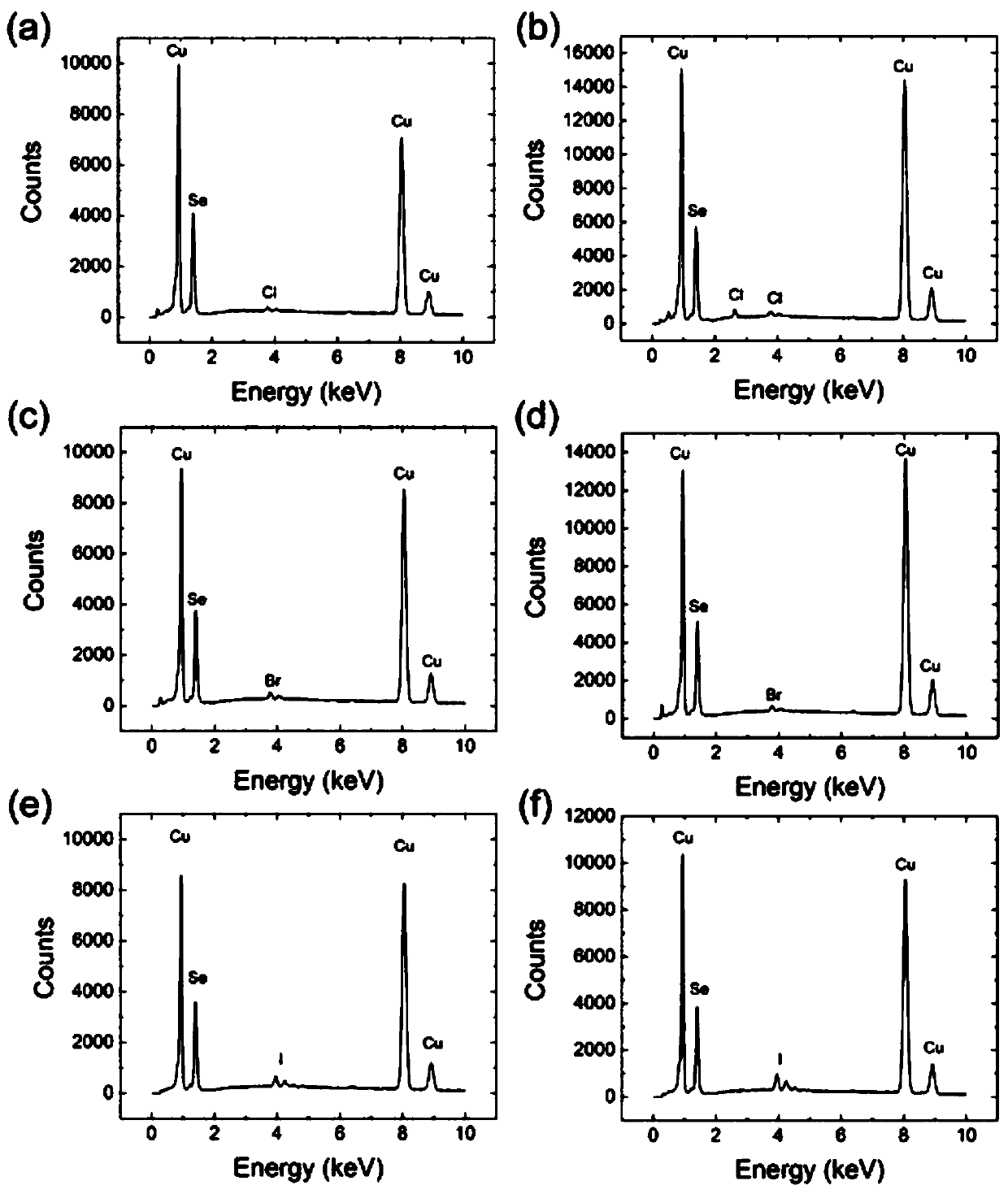

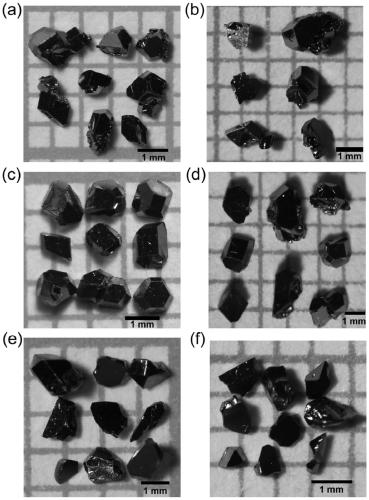

[0026]Weigh 1.1g of Cu 2 Se and 100mg TeCl 4 The powder is ground and mixed with a mortar and placed in a quartz tube that has been pickled and dried. After the quartz tube containing the above growth materials is vacuum-sealed, it is placed in a high-temperature tube furnace with two temperature zones and transported by chemical vapor phase. The temperature of the growth end is 500°C, the temperature of the raw material end is 600°C, grow for 10 days under this temperature gradient, and finally cool naturally to room temperature to obtain high-quality Cu 2 Se 0.98 Cl 0.02 Single crystal, the largest dimension is about 1.5mm.

Embodiment 2

[0028] Weigh 1.1g of Cu 2 Se and 150mg of TeCl 4 The powder is ground and mixed with a mortar and placed in a quartz tube that has been pickled and dried. After the quartz tube containing the above growth materials is vacuum-sealed, it is placed in a high-temperature tube furnace with two temperature zones and transported by chemical vapor phase. The temperature of the growth end is 500°C, the temperature of the raw material end is 600°C, grow for 10 days under this temperature gradient, and finally cool naturally to room temperature to obtain high-quality Cu 2 Se 0.95 Cl 0.05 Crystals, about 1.5mm in largest dimension.

Embodiment 3

[0030] Weigh 1.1g of Cu 2 Se and 100mg of TeBr 4 The powder is ground and mixed with a mortar and placed in a quartz tube that has been pickled and dried. After the quartz tube containing the above growth materials is vacuum-sealed, it is placed in a high-temperature tube furnace with two temperature zones and transported by chemical vapor phase. The temperature of the growth end is 550°C, the temperature of the raw material end is 650°C, grow for 10 days under this temperature gradient, and finally cool naturally to room temperature to obtain high-quality Cu 2 Se 0.97 Br 0.03 Single crystal, the largest dimension is about 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com