Preparation method of machine-made water-soluble polyvinyl alcohol nonwoven shopping bag

A technology of polyvinyl alcohol and non-woven fabrics, applied in textiles and papermaking, improved handle fibers, fiber types, etc., can solve the problem of low processing efficiency of polyvinyl alcohol non-woven fabrics, certain limitations in application fields, and poor heat dissipation Sealing performance and other issues, to achieve the effect of improved mechanical properties, increased elongation at break, and firm fiber nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

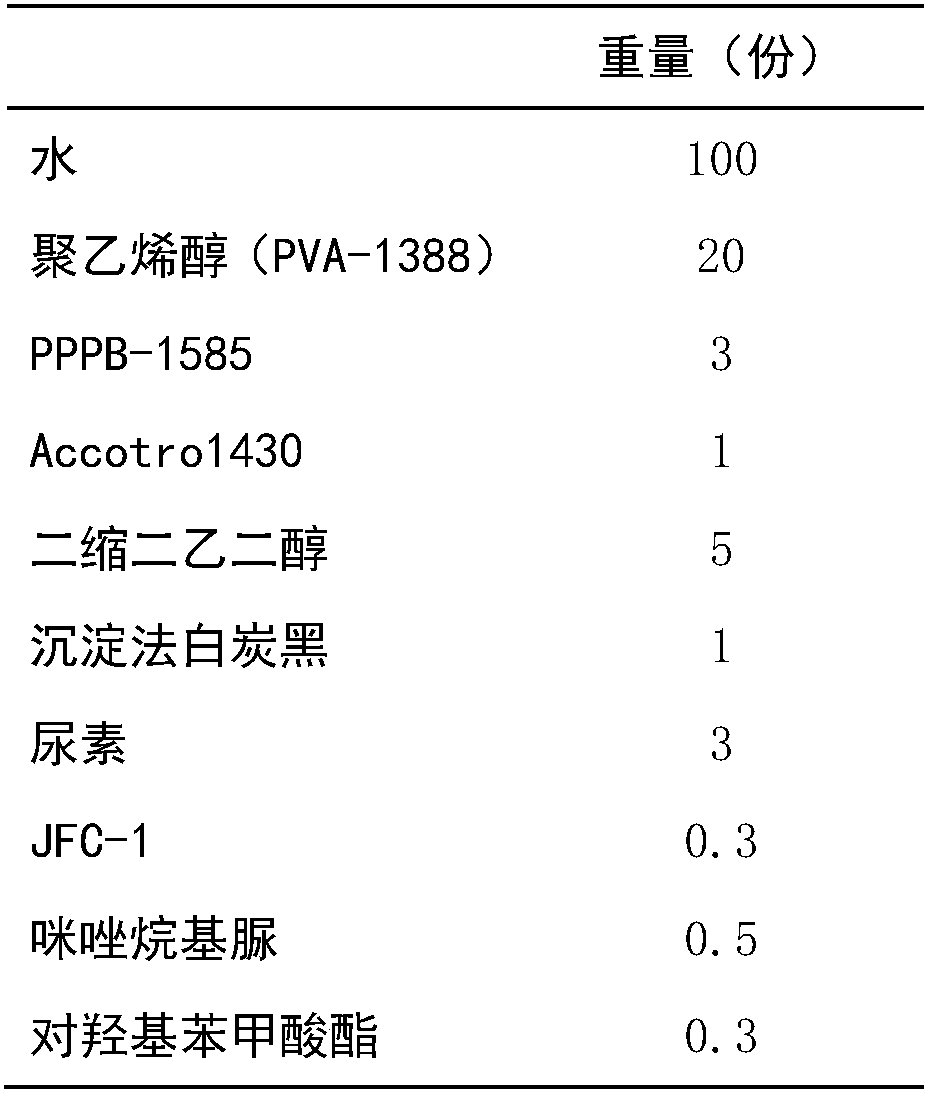

[0030] (1) The sizing agent includes the following components in parts by weight (see Table 1):

[0031] Table 1

[0032]

[0033] After measuring the materials in the above components, add them into a dissolution vessel with a heating jacket, raise the temperature to 95°C for 2 hours under stirring (50 rpm), mix and dissolve for 2 hours, keep the temperature at 90°C for 30 minutes, and then cool down to room temperature. Material spare. It is the finishing agent required for the polyvinyl alcohol (PVA) nonwoven fabric described in the present invention when padding and sizing;

[0034] (2) Specification of polyvinyl alcohol non-woven fabric for finishing (GSM): 15g / m2;

[0035] (3) The polyvinyl alcohol non-woven fabric (GSM) after padding and gluing is: 30g / m2.

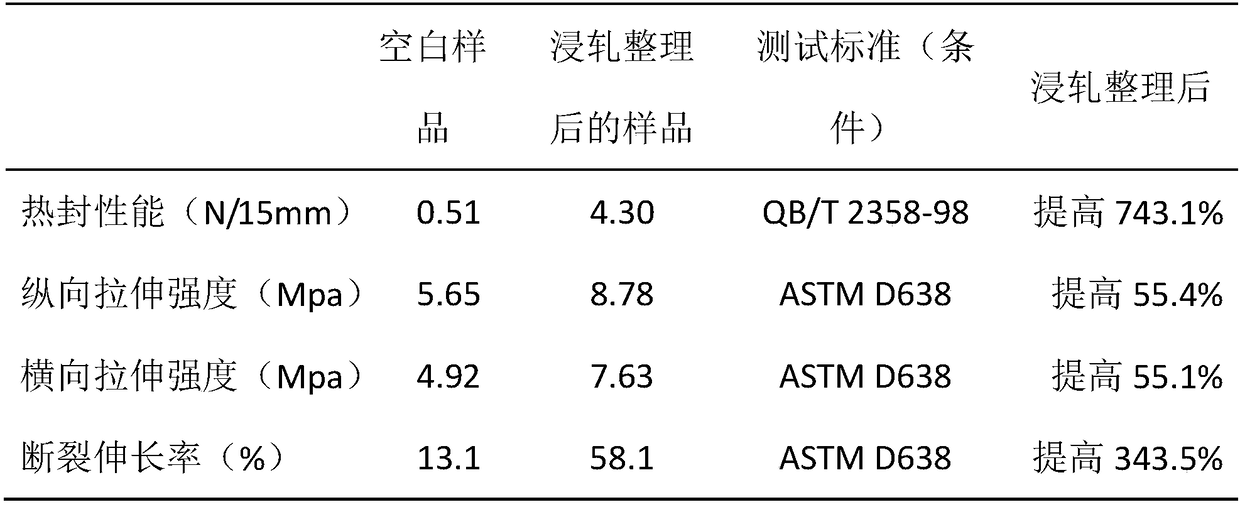

[0036] Table 2 shows the performance comparison results of the PVA non-woven fabric after padding and the PVA non-woven fabric without padding (blank sample).

[0037] Table 2

[0038]

[0039] It can be ...

Embodiment 2

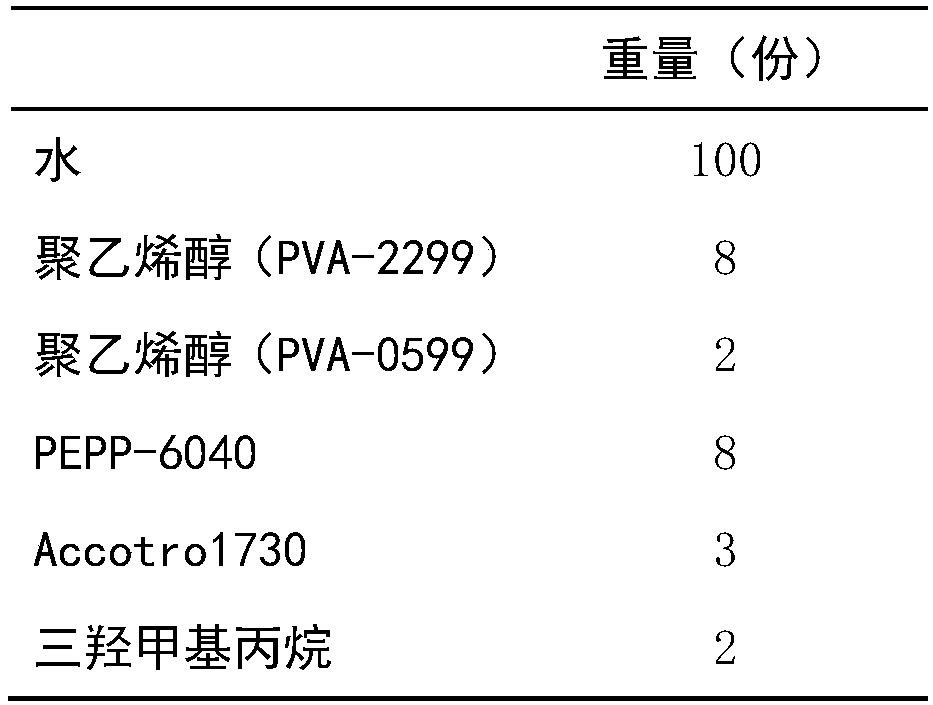

[0041] (1) The sizing agent includes the following components in parts by weight (see Table 3):

[0042] table 3

[0043]

[0044]

[0045]After measuring the materials in the above components, add them into a dissolution vessel with a heating jacket, raise the temperature to 95°C for 3 hours under stirring (50 rpm), mix and dissolve for 3 hours, and keep the temperature at 90°C for 30 minutes, then cool down to room temperature and leave. Material spare. It is the finishing agent required for the polyvinyl alcohol (PVA) nonwoven fabric described in the present invention when padding and sizing;

[0046] (2) Specification of polyvinyl alcohol non-woven fabric for finishing (GSM): 80g / m2;

[0047] (3) The polyvinyl alcohol non-woven fabric (GSM) after padding and gluing is: 104g / m2.

[0048] Table 4 shows the performance comparison results of the polyvinyl alcohol nonwoven fabric after padding finishing and the polyvinyl alcohol nonwoven fabric (blank sample) without p...

Embodiment 3

[0053] (1) The sizing agent includes the following components in parts by weight (see Table 5):

[0054] table 5

[0055]

[0056] After measuring the materials in the above components, add them into a dissolution vessel with a heating jacket, raise the temperature to 95°C for 4 hours under stirring (50 rpm), mix and dissolve for 4 hours, and keep the temperature at 90°C for 30 minutes, then cool down to room temperature and leave. Material spare. It is the finishing agent required for the polyvinyl alcohol (PVA) nonwoven fabric described in the present invention when padding and sizing;

[0057] (2) Specification of polyvinyl alcohol non-woven fabric for finishing (GSM): 50g / m2;

[0058] (3) The polyvinyl alcohol non-woven fabric (GSM) after padding and gluing is: 75g / m2.

[0059] Table 6 shows the performance comparison results of the polyvinyl alcohol nonwoven fabric after padding finishing and the polyvinyl alcohol nonwoven fabric (blank sample) without padding finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com