Water stopping material for steel pipe pile cofferdam buckle

A technology of water-stop material and steel pipe pile, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of poor water-stop effect and difficult removal in the later stage, and achieves low strength, excellent water-stop effect, and a wide range of sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

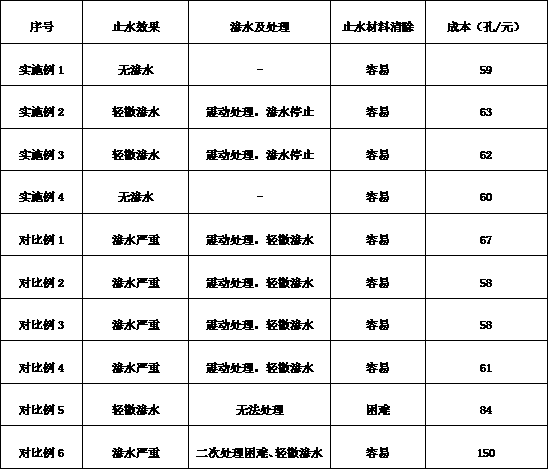

Examples

Embodiment 1

[0019] A water-stop material, prepared by mixing the following raw materials by weight: 100 parts of medium-coarse sand with a particle size of 4.75 mm, 10 parts of expansive soil, 3.3 parts of a saw with an aspect ratio of 2:1 and a diameter of 1.5 mm. sawdust.

Embodiment 2

[0021] A water-stopping material prepared by mixing the following raw materials in parts by weight: 90 parts of stone powder with a particle diameter of 2 mm, 11 parts of bentonite, and 3 parts of straw powder with an aspect ratio of 2:1 and a diameter of 2 mm.

Embodiment 3

[0023] A water-stop material is prepared by mixing the following raw materials in parts by weight: 110 parts of coarse sand with a particle diameter of 6 mm, 9 parts of expansive soil, and 4 parts of bagasse with an aspect ratio of 5:1 and a diameter of 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com