Method for improving water binding capacity of frozen dish of beef through microbial fermentation multilevel processing

A microbial fermentation and water-holding technology, which is applied in food ultrasonic treatment, food science, ultra-high pressure food processing, etc., can solve the problem that myofibrillar protein decomposition is difficult to fully exert, cannot arouse consumers' desire to buy, and the color of beef becomes lighter and other problems, to achieve the effect of decreasing the shear force value, enhancing the water holding capacity and improving the water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

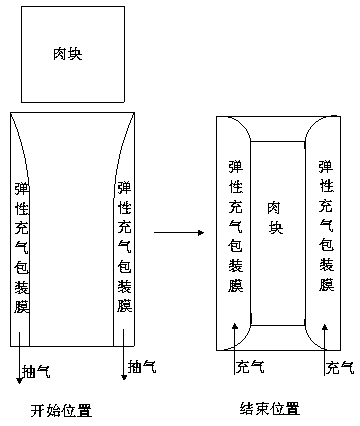

Image

Examples

Embodiment 1

[0055]A method for improving the water holding capacity of beef frozen dishes through multi-stage microbial fermentation treatment, comprising the following steps:

[0056] Step 1. Pre-cool the slaughtered cattle in a three-stage pre-cooling pool, and perform ultrasonic treatment with an ultrasonic generator while pre-cooling. The frequency of the ultrasonic generator is 40 Hz and the power is 3.5 kilowatts; In the first pre-cooling pool, the ultrasonic generator was turned on for 5 minutes and stopped for 5 minutes. The treatment time was 30 minutes, and the temperature of the pre-cooling pool was controlled at 8°C; Stop for 7 minutes, the processing time is 80 minutes, the temperature of the pre-cooling pool is controlled at 4°C; when the cattle are placed in the third pre-cooling pool, the ultrasonic generator is continuously turned on for 20 minutes, and the temperature of the pre-cooling pool is controlled at 0°C; After cooling and ultrasonic treatment, take out the cow a...

Embodiment 2

[0070] A method for improving the water holding capacity of beef frozen dishes through multi-stage microbial fermentation treatment, comprising the following steps:

[0071] Step 1. Pre-cool the slaughtered cattle in a three-stage pre-cooling pool, and perform ultrasonic treatment with an ultrasonic generator while pre-cooling. The frequency of the ultrasonic generator is 40 Hz and the power is 3.5 kilowatts; In the first pre-cooling pool, the ultrasonic generator was turned on for 5.5 minutes and stopped for 5.5 minutes. The treatment time was 35 minutes, and the temperature of the pre-cooling pool was controlled at 9°C; Stop for 7.5 minutes, the treatment time is 90 minutes, the temperature of the pre-cooling pool is controlled at 5°C; when the cattle are placed in the third pre-cooling pool, the ultrasonic generator is continuously turned on for 23 minutes, and the temperature of the pre-cooling pool is controlled at 2°C; After cooling and ultrasonic treatment, take out the...

Embodiment 3

[0085] A method for improving the water holding capacity of beef frozen dishes through multi-stage microbial fermentation treatment, comprising the following steps:

[0086] Step 1. Pre-cool the slaughtered cattle in a three-stage pre-cooling pool, and perform ultrasonic treatment with an ultrasonic generator while pre-cooling. The frequency of the ultrasonic generator is 40 Hz and the power is 3.5 kilowatts; In the first pre-cooling pool, the ultrasonic generator is turned on for 6 minutes and stopped for 6 minutes. The processing time is 30-40 minutes, and the temperature of the pre-cooling pool is controlled at 10°C; minutes, stop for 8 minutes, the processing time is 100 minutes, the temperature of the pre-cooling pool is controlled at 6°C; when the cattle are placed in the third pre-cooling pool, the ultrasonic generator is continuously turned on for 25 minutes, and the temperature of the pre-cooling pool is controlled at 0-3°C ; After three times of pre-cooling and ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com