Method for improving port dish water retentiveness through secondary microorganism fermentation

A microbial fermentation and water-holding technology, applied in the fields of food processing and microbial fermentation, can solve the problems of unstable emulsification, loose tissue structure, and insufficient toughness of sausages, and achieve good color enhancement, enhanced hydration capacity, and avoid adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

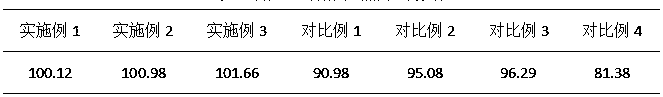

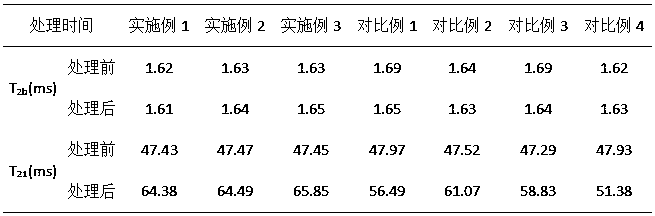

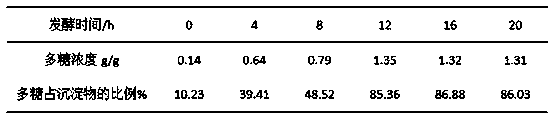

Embodiment 1

[0054] A method utilizing secondary microbial fermentation to improve the water holding capacity of pork dishes, comprising the following steps:

[0055] Step 1: Cut the washed raw pork into pork slices with a thickness of 1-3cm, then mix the pork slices with seasonings (including starch at 2.5% by weight of pork slices, edible salt at 1.5% by weight of pork slices, pork Sugar 3.0% by weight of sliced pork, monosodium glutamate 0.1% by weight of sliced pork, soy sauce 1.2% by weight of sliced pork, cooking wine 1.6% by weight of sliced pork), rice protein (1.0% by weight of sliced pork) and transglutaminase (0.3% by weight of pork slices) after mixing, the first mixture is obtained, and then the first mixture is subjected to intermittent ultra-high pressure treatment (the specific operation is: treat with ultra-high pressure under a pressure of 250MPa for 5 minutes, and then an interval of 5 minutes is a treatment cycle, The first mixture is subjected to 5 treatment ...

Embodiment 2

[0062] A method utilizing secondary microbial fermentation to improve the water holding capacity of pork dishes, comprising the following steps:

[0063] Step 1: Cut the washed raw pork into pork slices with a thickness of 1-3cm, then mix the pork slices with seasonings (including starch at 3.0% by weight of pork slices, edible salt at 2.0% by weight of pork slices, pork Sugar 3.5% by weight of sliced pork, monosodium glutamate 0.15% by weight of sliced pork, soy sauce 1.4% by weight of sliced pork, cooking wine 1.8% by weight of sliced pork), rice protein (2.0% by weight of sliced pork) and transglutaminase (0.5% by weight of pork slices) after mixing, the first mixture is obtained, and then the first mixture is subjected to intermittent ultra-high pressure treatment (the specific operation is: treat with ultra-high pressure under a pressure of 300MPa for 6 minutes, and then an interval of 6 minutes is a treatment cycle, Carry out 6 treatment cycles on the first mix...

Embodiment 3

[0070] A method utilizing secondary microbial fermentation to improve the water holding capacity of pork dishes, comprising the following steps:

[0071] Step 1: Cut the washed raw pork into pork slices with a thickness of 1-3cm, then mix the pork slices with seasonings (including starch at 2.8% by weight of pork slices, edible salt at 1.75% by weight of pork slices, pork Sugar 3.25% by weight of sliced pork, monosodium glutamate 0.125% by weight of sliced pork, soy sauce 1.3% by weight of sliced pork, cooking wine 175% by weight of sliced pork), rice protein (1.5% by weight of sliced pork) and transglutaminase (0.4% by weight of pork slices) after mixing, the first mixture is obtained, and then the first mixture is subjected to intermittent ultra-high pressure treatment (the specific operation is: treat with ultra-high pressure at a pressure of 275MPa for 5.5 minutes, and then take an interval of 5.5 minutes as a treatment cycle, the first mixture is subjected to 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com