Fast degradation on-site treatment process for kitchen garbage

A kitchen waste, rapid degradation technology, applied in water/sewage treatment, anaerobic digestion treatment, biological water/sewage treatment, etc. Degradation efficiency, effect of preventing rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

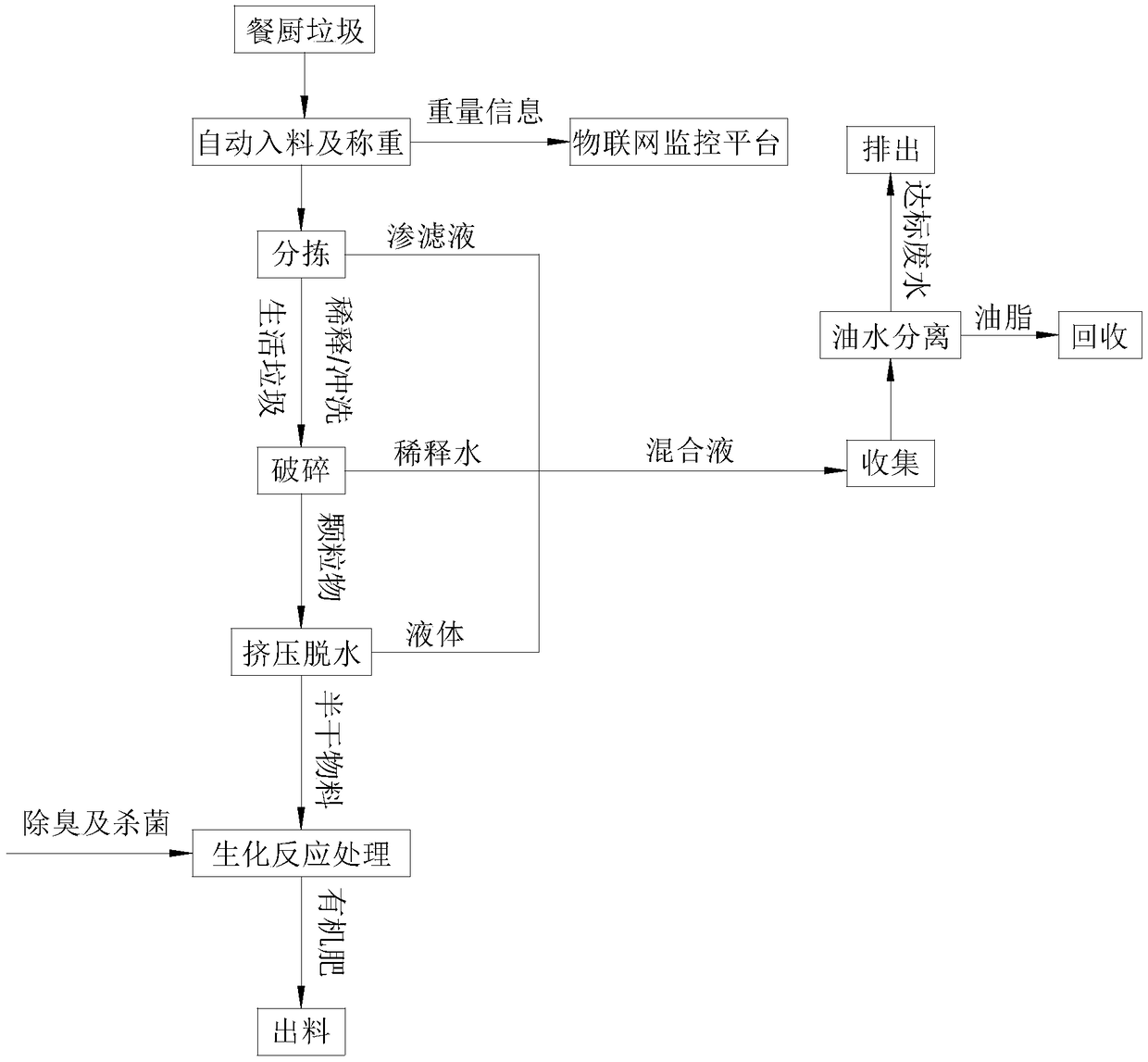

[0032] see figure 1 , the present embodiment provides a rapid degradation in-situ treatment process for kitchen waste, which includes the following steps:

[0033] (1) Automatic feeding and weighing

[0034] The food waste is weighed in real time through the remote weighing sensor, and the food waste is automatically fed to the next step through the automatic hoist; among them, the weighing data of the food waste is transmitted to the food IoT monitoring platform.

[0035] (2) Sorting and crushing

[0036] Sorting and separating the domestic waste and leachate in the kitchen waste, and breaking the separated domestic waste into particles with a diameter of 10-30mm; among them, when sorting the domestic waste, it can be sorted manually (such as the existing Garbage classification processing method) plastic products, instant noodle boxes, cans, glass bottles, dishes, spoons, chopsticks and other domestic waste; and the sorted materials can be crushed by a crusher. Of course, ...

Embodiment 2

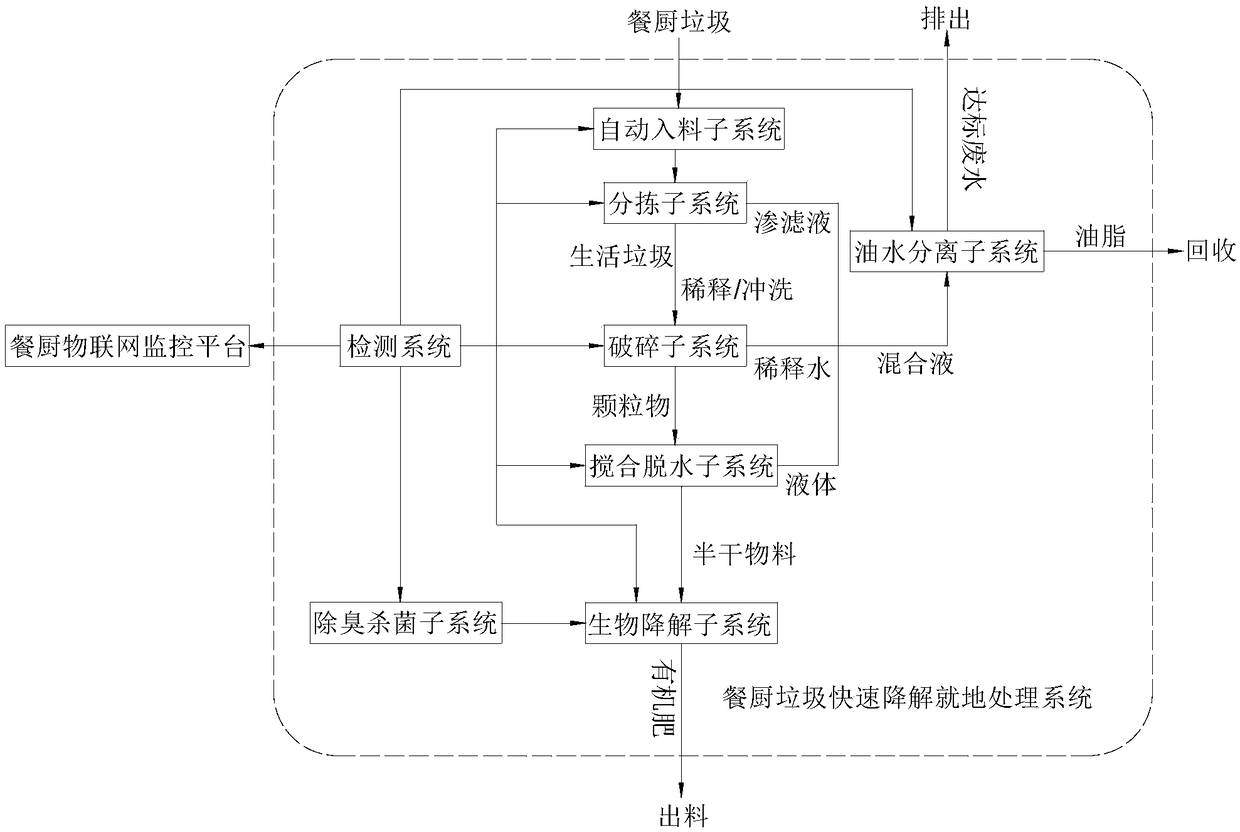

[0048] see figure 2 , this embodiment provides a fast-degradation in-situ treatment system for food waste, which applies the fast-degradation in-situ treatment process for food waste in Example 1, and the fast-degradation in-situ treatment system for food waste includes an automatic feeding subsystem, Sorting subsystem, crushing subsystem, mixing and dehydration subsystem, biodegradation subsystem, oil-water ionization system, deodorization and sterilization subsystem and detection system.

[0049] The automatic feeding subsystem is used to transport food waste to the sorting subsystem. The automatic feeding subsystem may include an automatic elevator, a storage box, a feeding switch, a feeding controller, and a weight detection device. Wherein, the automatic elevator in this embodiment is used to transport food waste to the sorting subsystem. There may be multiple storage boxes, and the multiple storage boxes are respectively set in the kitchens of multiple users to collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com