Impact resistant PET/LCP (Polyethylene Terephthalate/Liquid Crystal Polymer) composite material

A technology of composite materials and raw materials, applied in the field of impact-resistant PET/LCP composite materials, can solve the problems of high price of LCP materials, brittle products of LCP materials, and reduced comprehensive performance, so as to reduce LCP content, improve brittleness, and improve comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

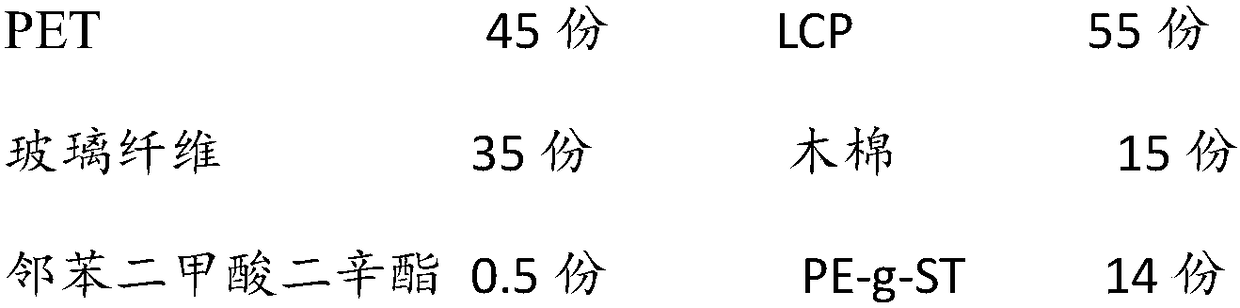

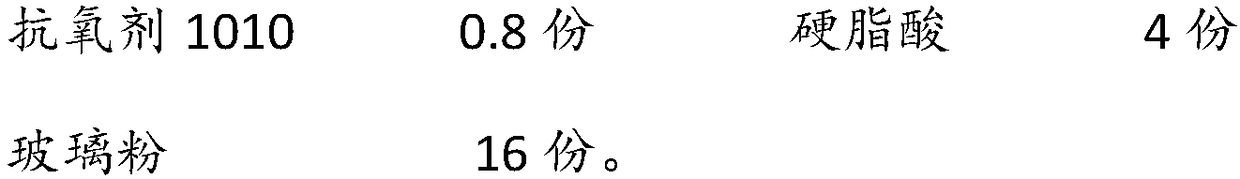

[0020] Impact-resistant PET / LCP composite material, its raw material components in parts by mass are:

[0021]

[0022]

[0023] Its preparation method is:

[0024] Weigh PET, LCP, glass fiber, kapok, dioctyl phthalate, PE‐g‐ST, antioxidant 1010, stearic acid and glass powder of the above components;

[0025] Put the PET and LCP in the drier, the temperature of the drier is 110°C, the drying time is 30min, and set aside;

[0026] Add the dried PET and LCP, dioctyl phthalate, PE‐g‐ST, antioxidant 1010, stearic acid and glass powder into the high mixer, the temperature of the high mixer is 80°C, and the mixing time is 100min, obtain mixed material;

[0027] Put the mixture into the twin-screw extruder, control the screw speed to 600r / min, and the temperature of each zone in the cavity is as follows: the temperature of the first zone is 255°C, the temperature of the second zone is 270°C, the temperature of the third zone is 275°C, and the temperature of the fourth zone is...

Embodiment 2

[0029] Impact-resistant PET / LCP composite material, its raw material components in parts by mass are:

[0030]

[0031]

[0032] Its preparation method is:

[0033] Weigh PET, LCP, glass fiber, sisal, dibutyl phthalate, ABS-g-MAH, antioxidant 264, butyl stearate and asbestos powder of the above components;

[0034] Put the PET and LCP in the drier, the temperature of the drier is 104°C, the drying time is 33min, and set aside;

[0035] Add the dried PET and LCP, dibutyl phthalate, ABS‐g‐MAH, antioxidant 264, butyl stearate and asbestos powder into the high mixer, the temperature of the high mixer is 76°C, and mix Time is 120min, obtains mixed material;

[0036] Put the mixture into the twin-screw extruder, control the screw speed to 580r / min, and the temperature of each zone in the cavity is as follows: the temperature of the first zone is 263°C, the temperature of the second zone is 262°C, the temperature of the third zone is 273°C, and the temperature of the fourth z...

Embodiment 3

[0038] Impact-resistant PET / LCP composite material, its raw material components in parts by mass are:

[0039]

[0040] Its preparation method is:

[0041] Weigh PET, LCP, glass fiber, flax, dioctyl phthalate, PP‐g‐MAH, antioxidant 1076, oleamide and mica powder of the above components;

[0042] Put the PET and LCP in the drier, the temperature of the drier is 90°C, the drying time is 40min, and set aside;

[0043] Add the dried PET and LCP, dioctyl phthalate, PP‐g‐MAH, antioxidant 1076, oleamide and mica powder into the high mixer, the temperature of the high mixer is 60°C, and the mixing time is 160min , get the mixture;

[0044] Put the mixture into the twin-screw extruder, control the screw speed to 400r / min, and the temperature of each zone in the cavity is as follows: the temperature of the first zone is 265°C, the temperature of the second zone is 260°C, the temperature of the third zone is 265°C, and the temperature of the fourth zone is 265°C. The temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com