Preparation and application of a tackifier for addition-type silicone heat-conducting potting adhesive

A heat-conducting potting and organosilicon technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems such as the failure of the platinum catalyst of the addition type silicone rubber, the unsatisfactory stability and adhesion, etc. To achieve excellent bonding effect, reduce self-polymerization, reduce the effect of substituent groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the tackifier for the addition-type silicone heat-conducting potting adhesive of the present invention comprises the following steps:

[0033]Step 1: Add 480-520 parts by weight of vinyl-containing polysiloxane with hydroxyl-terminated side groups and 608-658 parts by weight of ND-42 (silane coupling agent) into a reactor with constant temperature stirring function, and stir (stirring speed is 200-220 rev / min) to 115±2°C, add 1-2 parts by weight of alkali glue, and keep warm for 10-30 minutes; wherein, in the polysiloxane with vinyl group in terminal hydroxyl side group , the hydroxyl content is 6%-8%wt, the ethylene content is 3%-4%wt; ND-42 is anilinomethyltriethoxysilane, which can be used in the bonding of silicone rubber with metal, plastic and other materials; Alkali gum is an alkaline catalyst, and the addition method of alkali gum is dropwise. In this embodiment, alkali gum is obtained by the following method: 500 parts of vinyl silicon...

Embodiment 1

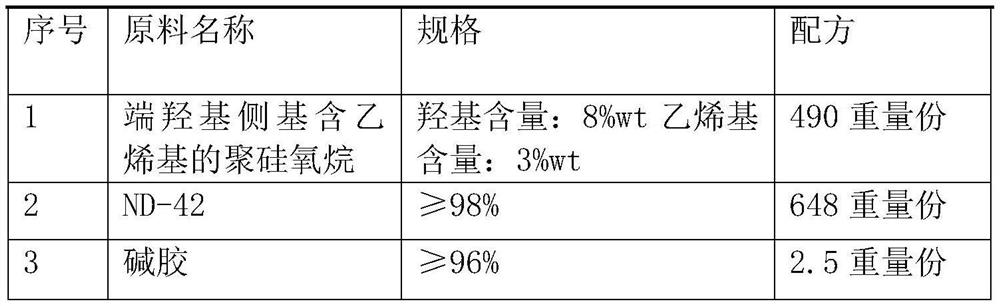

[0038] The raw materials used in this embodiment and the ratio of raw materials are as shown in Table 1:

[0039] Table 1 raw materials and ratio

[0040]

[0041] Using the ratio of raw materials in Table 1, the tackifier for the addition-type silicone heat-conducting potting adhesive of the present invention is prepared by the following steps:

[0042] (1) Add vinyl-containing polysiloxane and ND-42 into a reactor with a constant temperature function, adjust the mixer speed to 190 rpm, stir and heat up to 115±2°C, and then add alkali Glue, keep warm for 20 minutes;

[0043] (2) The temperature rises to 140±2°C, and the temperature is kept for 0.5 hours;

[0044] (3) The temperature is raised to 150±2°C, and the low molecular weight is removed by negative pressure for 1 hour; the temperature is lowered, and the material is discharged to obtain an addition-type silicone heat-conducting potting adhesive tackifier.

Embodiment 2

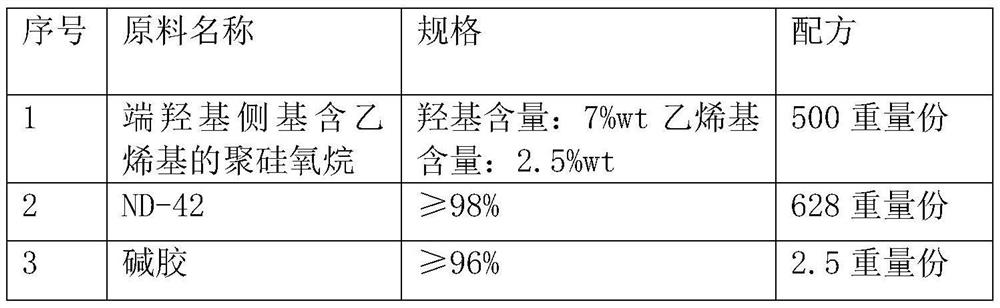

[0046] The raw materials used in this embodiment and the ratio of raw materials are as shown in Table 2:

[0047] Table 2 raw materials and ratio

[0048]

[0049] Using the raw material ratio in Table 2, the tackifier for the addition-type silicone heat-conducting potting adhesive of the present invention was prepared through the following steps:

[0050] (1) Add vinyl-containing polysiloxane and ND-42 into a reactor with a constant temperature function, adjust the mixer speed to 190 rpm, stir and heat up to 115±2°C, and then add alkali Glue, keep warm for 20 minutes;

[0051] (2) The temperature rises to 140±2°C, and the temperature is kept for 0.5 hours;

[0052] (3) The temperature is raised to 150±2°C, and the low molecular weight is removed by negative pressure for 1 hour; the temperature is lowered, and the material is discharged to obtain an addition-type silicone heat-conducting potting adhesive tackifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com