Preparation method of compact biomass particles

A biomass particle and compact technology, applied in the direction of biofuel, waste fuel, solid fuel, etc., can solve the problems of short burning time and loose raw materials, and achieve the effects of fast molding efficiency, high dryness, and high combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

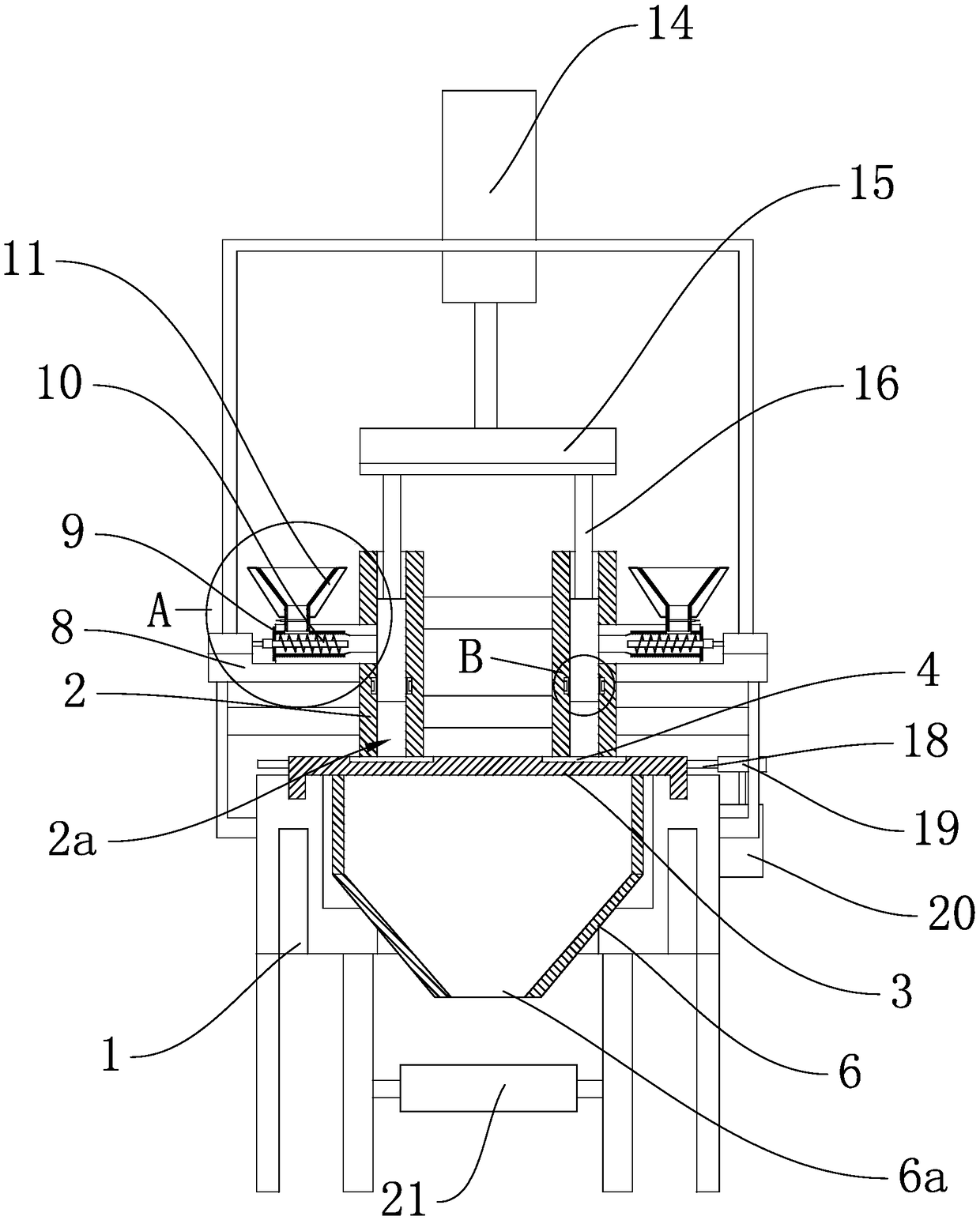

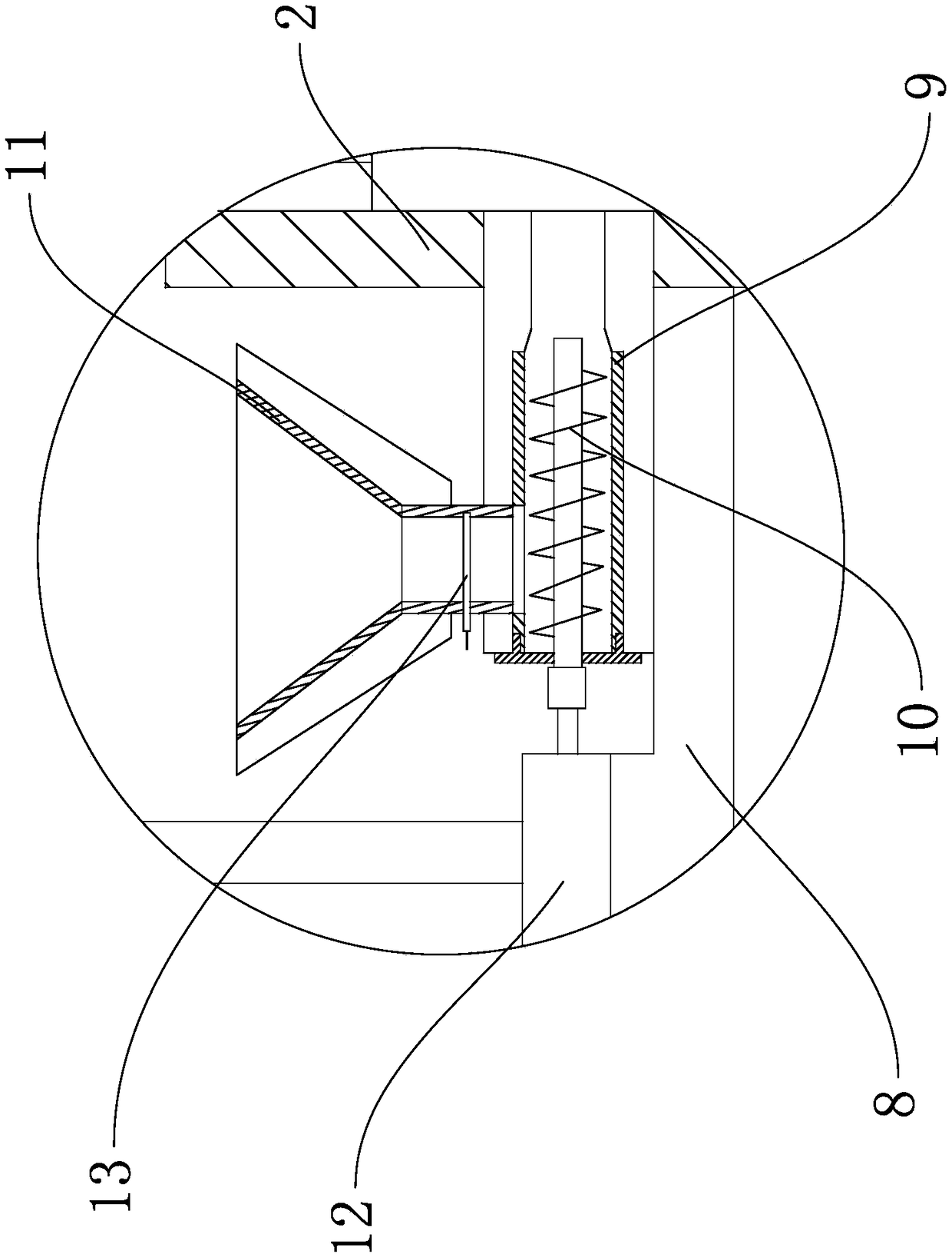

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

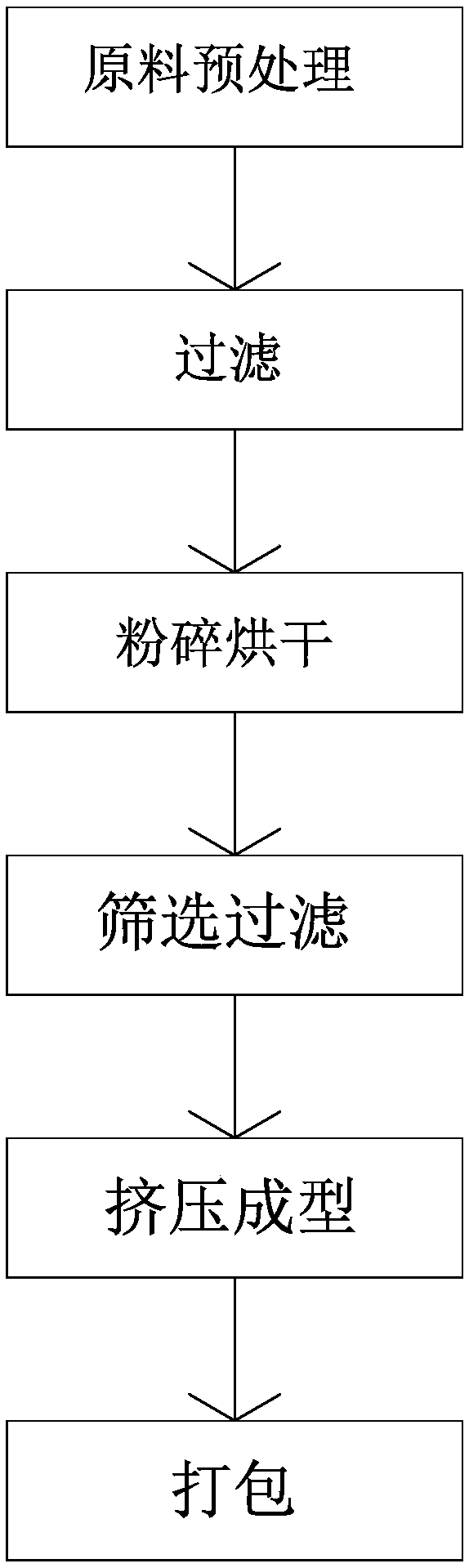

[0039] Such as figure 1 Shown, a kind of preparation method of compact biomass particle comprises the following steps:

[0040]S1. Raw material pretreatment: Mix crop straw, bagasse, bamboo chips, wood chips, combustion-promoting agent, anti-slagging agent, and aquatic plants to obtain mixed raw materials, and then heat them under air-isolated conditions. The heating temperature is controlled at 100-110°C, finally chop the mixed raw materials, and control the water content of the mixed raw materials at 13%-15%;

[0041] S2. Filtration: screen the large particles in the chopped mixed raw materials through a screen to remove the small particles;

[0042] S3, crushing: the mixed raw material is transported to a high-speed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com