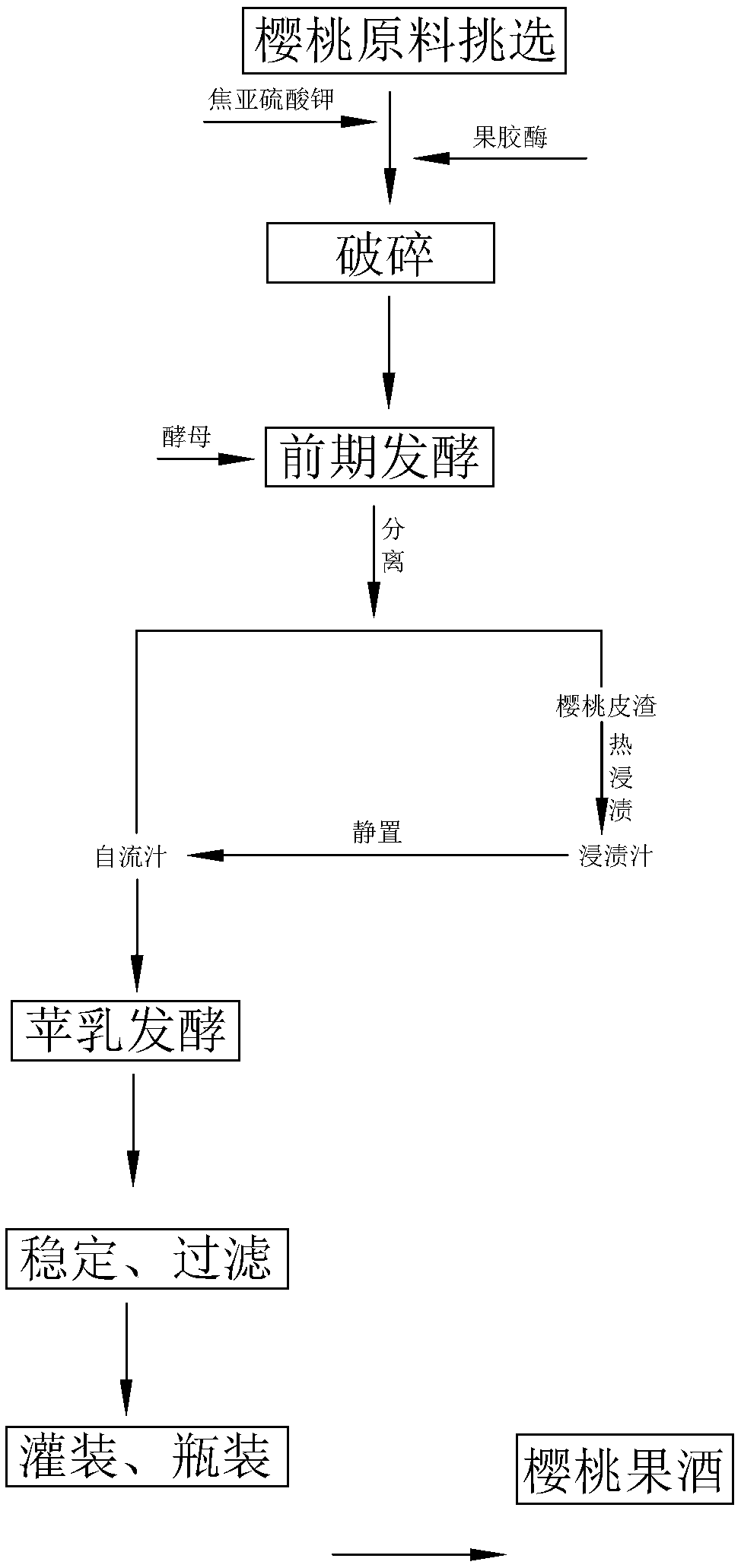

Cherry fruit wine making process

A technology of fruit wine brewing and cherry, which is applied in the field of wine making, can solve the problems affecting the taste, flavor and color of cherry wine, and achieve the effect of protecting color, sweet taste and low browning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of cherry fruit wine brewing process, comprises the following steps:

[0032] S1. Cherry raw material selection: select ripe, fresh, mildew-free, disease-free, and pesticide-free cherries, and remove moldy, rotten, shriveled and shriveled fruit and cherry branches and leaves;

[0033] S2. Crushing: crush the cherry raw materials within 2 hours after picking, control the pH of the crushed cherry juice to 3.0, and then take 1 ton of cherry as a reference, first add 20 g / t of potassium metabisulfite, and then add pectinase after 30 minutes 5 g / t;

[0034] S3. Pre-fermentation: Taking 1t of cherry as a reference, add 200g / t of yeast to the crushed cherry juice for fermentation. The fermentation temperature is 20°C, the fermentation time is 10 days, and the volatile acid is controlled at 0.2g / t during the fermentation process. L, when the amount of residual sugar in the cherry juice was less than 4g / L, the fermentation terminated;

[0035] After the fermentation, th...

Embodiment 2

[0047] A cherry fruit wine brewing process is carried out according to the operation steps in Example 1, the difference is that

[0048] S2. Crushing: crush the cherry raw materials 13 hours after picking, control the pH of the crushed cherry juice to 3.3, and then take 1 ton of cherry as a reference, first add potassium metabisulfite 60g / t, and then add pectinase 18 after 45 minutes g / t;

[0049] S3. Pre-fermentation: The pre-fermentation is realized through a fermenter. Taking 1 ton of cherries as a reference, 250g / t of yeast is added to the raw material obtained after destemming and crushing for fermentation. The fermentation temperature is 22°C and the fermentation time is 12 days. The volatile acid is controlled at 0.3 g / L, and when the residual sugar in the cherry juice is less than 4g / L, the fermentation is terminated;

[0050] After the fermentation, the cherry juice is separated to obtain artesian juice and cherry pomace. The cherry pomace is soaked at a temperature ...

Embodiment 3

[0060] A cherry fruit wine brewing process is carried out according to the operation steps in Example 1, the difference is that

[0061] S2. Crushing: crush the cherry raw materials 24 hours after picking, control the pH of the crushed cherry juice to 3.6, and then take 1 ton of cherry as a reference, first add potassium metabisulfite 100g / t, and then add pectinase 30 after 60min g / t;

[0062] S3. Pre-fermentation: The pre-fermentation is realized through a fermenter. Taking 1 ton of cherries as a reference, 300g / t of yeast is added to the raw material obtained after destemming and crushing for fermentation. The fermentation temperature is 25°C, and the fermentation time is 15 days. The volatile acid is controlled at 0.5 g / L, and when the residual sugar in the cherry juice is less than 4g / L, the fermentation is terminated;

[0063] After the pre-fermentation, the cherry juice is separated to obtain artesian juice and cherry pomace, the cherry pomace is soaked at a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com