Novel wide band gap semiconductor device and manufacturing method thereof

A power semiconductor and wide bandgap technology, applied in the field of new wide bandgap power semiconductor devices and their production, can solve the problems of miniaturization and high power density of power electronic equipment, high conduction voltage drop of MOS body diode, and increase of equipment volume. and cost to improve conduction loss characteristics, reduce system size and parasitic parameters, and improve the effect of peak electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

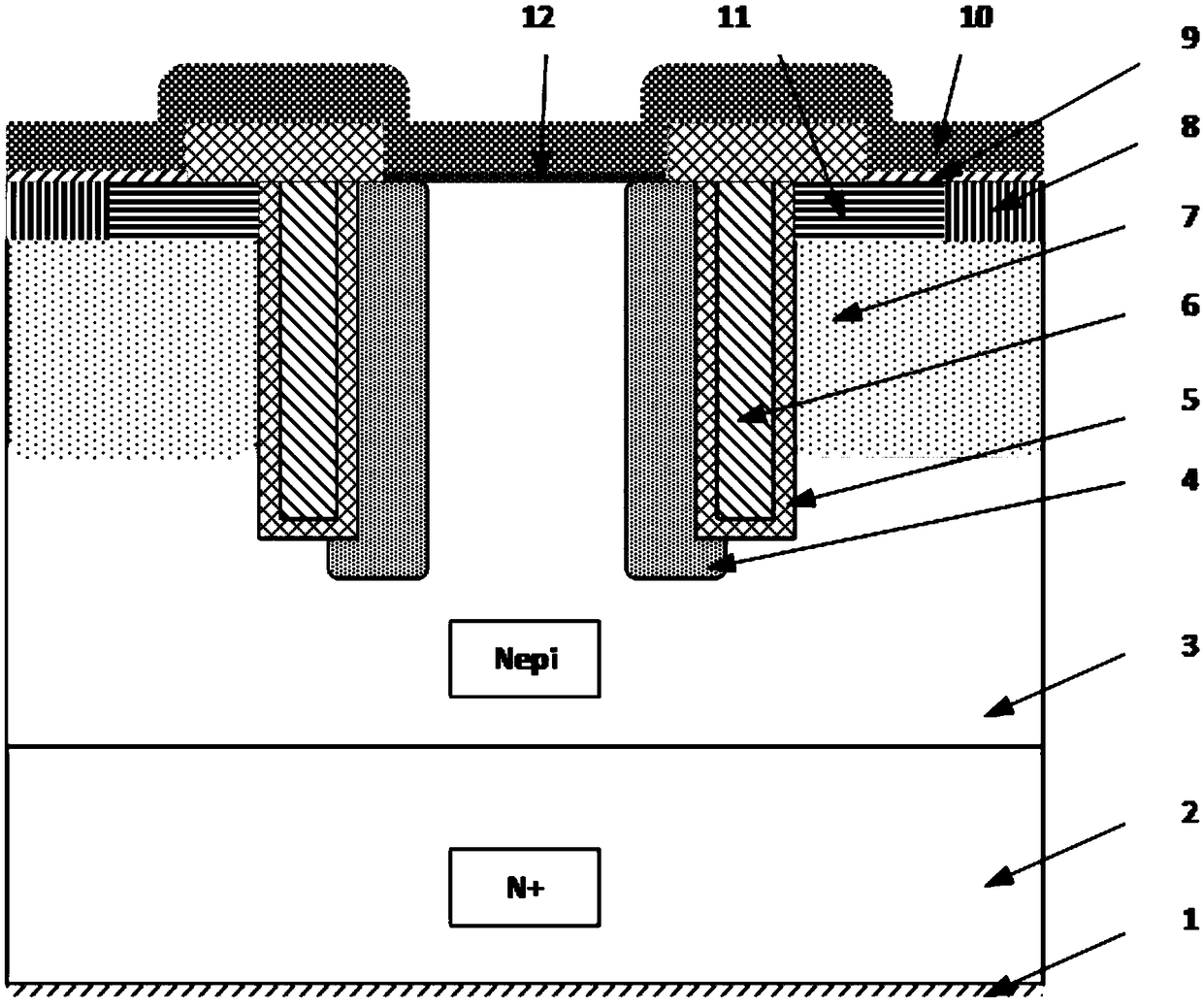

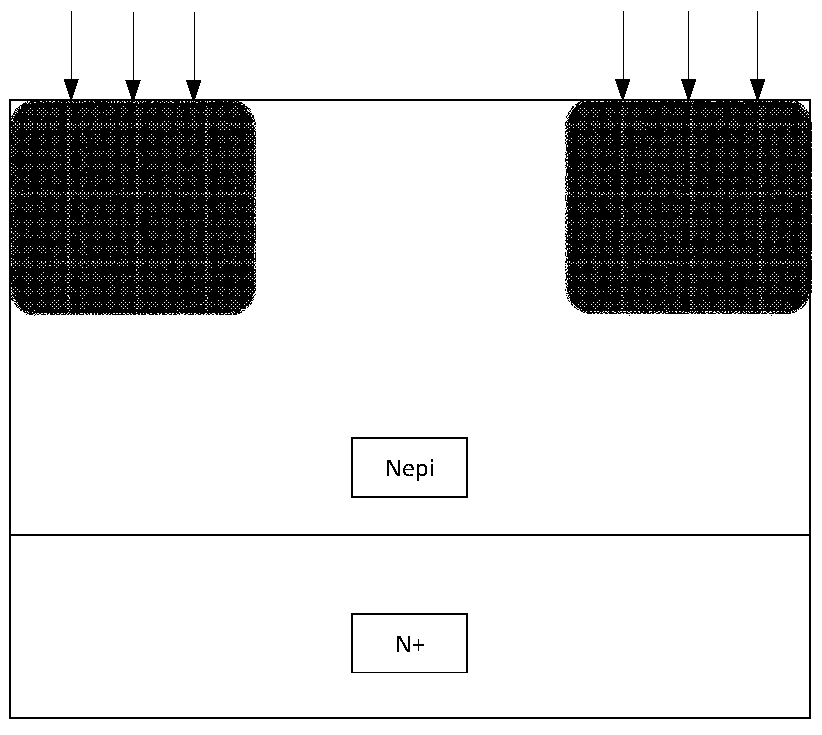

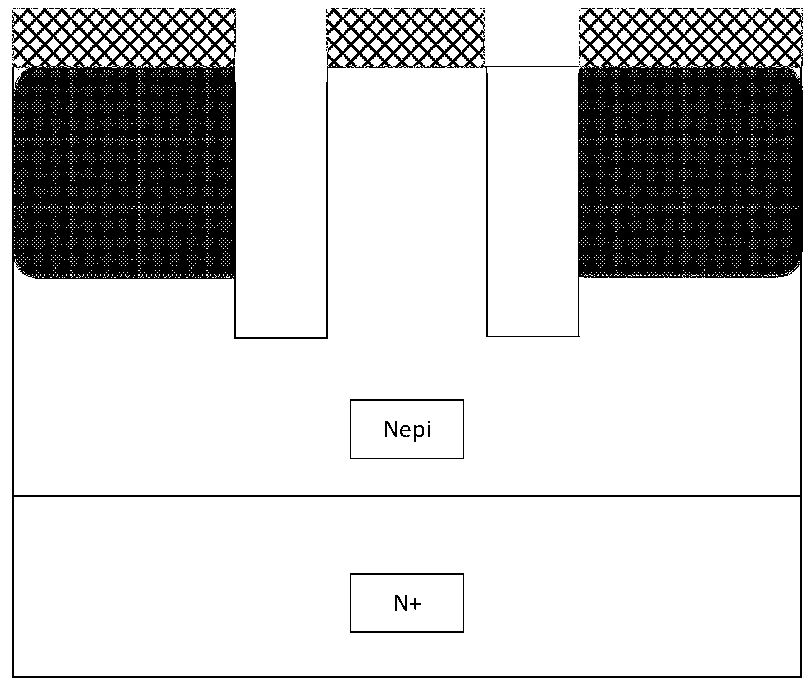

[0032] Such as figure 1 As shown, a new wide-bandgap power semiconductor device includes an N+ substrate 2, an N-type epitaxial layer 3 deposited on the N+ substrate 2, a PWELL region 7 (ie, a P well region) located inside the epitaxial layer, and a set The N+ implantation region 11 and the P+ implantation region 8 in the P well region, the plurality of trenches arranged inside the P well region, the ohmic contact electrode 9 arranged on the top of the N+ implantation region 11 and the P+ implantation region 8, and the grooves The P-type doped layer 4 on one side, the Schottky contact electrode 12 arranged on the top between the P-type doped layers 4, the groove extends toward the substrate, and the POLY gate 6 is filled in the groove, and the POLY gate 6 The oxide layer 5 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com