A device for assisting vacuum precooling of rice

An auxiliary device and pre-cooling technology, which is applied to household refrigeration devices, applications, household appliances, etc., can solve the problems of increasing the risk of microbial contamination, uneven moisture distribution of rice, and reducing quality, so as to avoid quality deterioration and restrain outward Evaporation, the effect of maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

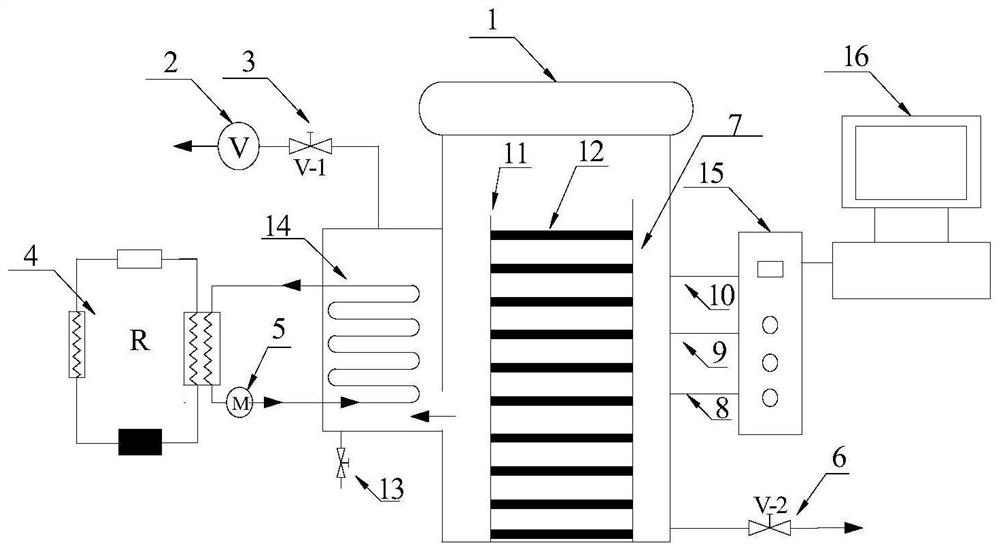

[0034] The auxiliary device group 7 involved in the present invention is used together with the vacuum precooling combination for precooling rice. Among them, the vacuum pre-cooler includes a condensation system, a vacuum system, a data collection system, and a data processing and operating system, which are connected in sequence, including a refrigeration unit 4, a condenser 14, a cryogenic liquid circulation pump 5, a vacuum box 1, a vacuum pump 2, Pneumatic valve 3, exhaust valve 6, drain valve 13, weight sensor 8, pressure sensor 9 and temperature sensor 10, data processor 15 and computer 16; the condensing system is composed of refrigeration unit 4, cryogenic liquid circulation pump 5 and condenser 14 The vacuum system consists of a vacuum box 1 and a vacuum pump 2; the data collection system consists of a weight sensor 8, a pressure sensor 9 and a temperature sensor 10; the data processing and operating system consists of a data processor 15 and a computer 16. Auxiliary ...

Embodiment 2

[0040] (1) Cook the mixture of rice and water (the mass ratio of rice and water is 1:1.5), by controlling the weight of the mixture and the size of the container, the height of the cooked rice is 200mm, and the cooking time is half an hour. The method is steam cooking, and the length and width distribution of rice is 1000mm.

[0041] (2) The auxiliary device group was first cleaned with tap water, and then placed in a cold storage at -18±2°C for treatment, taken out after 4 hours, then soaked in low-temperature alcohol with a mass fraction of 75% for 30 seconds for disinfection, and finally Rinse with tap water at 4±1°C for another 2 minutes.

[0042] (3) Wrap the cooked rice with sterilized gauze, then put it into the vacuum box of the vacuum pre-cooler, insert the temperature probe into the geometric center of the rice, close the vacuum box door of the vacuum pre-cooler, Turn on the vacuum pump and adjust the pressure drop rate coefficient of the vacuum pump to 0.2min -1 ,...

Embodiment 3

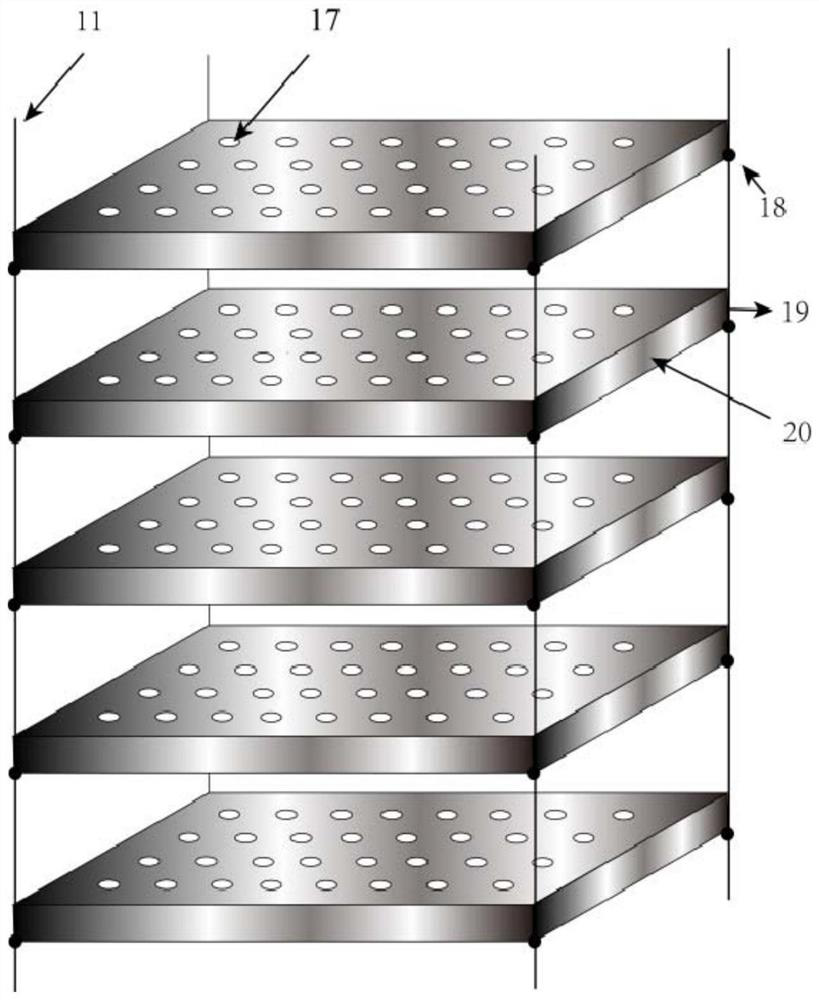

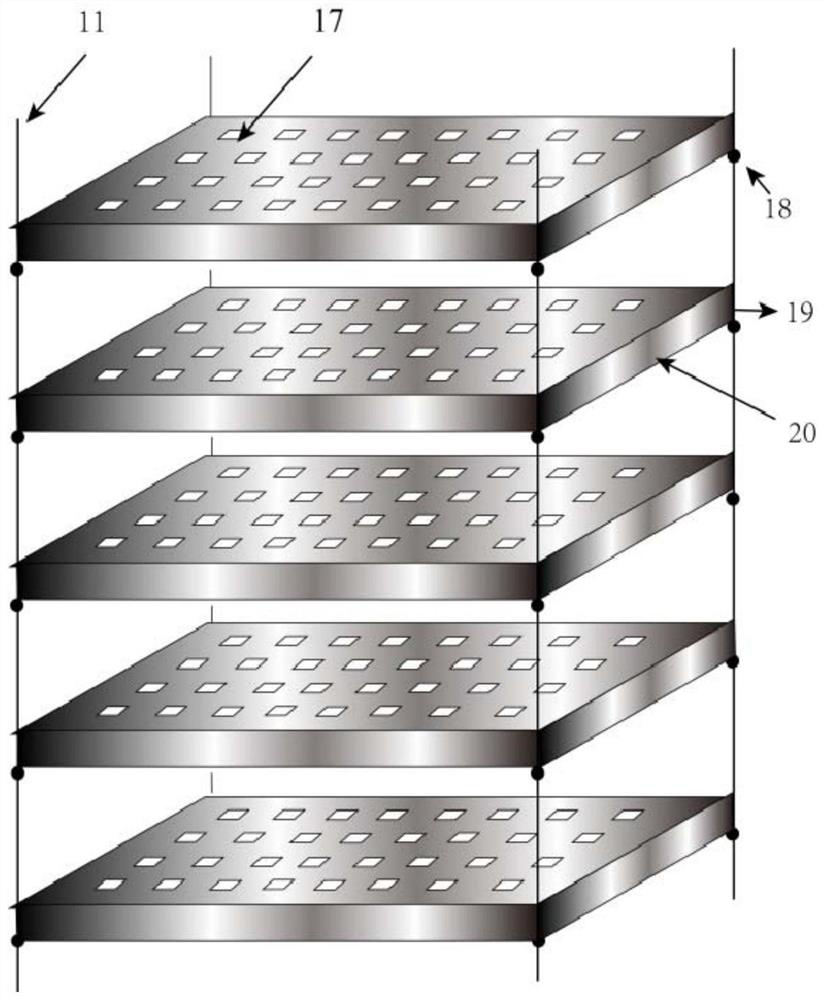

[0061] Embodiment 3 is the same as embodiment 1 method of operation, and the difference is that the parameters of the device itself are different. The device selected in embodiment 3 is different from the device in embodiment 1 in that the distribution of the hollow cylinder on the hollow cuboid, in embodiment 2 The selected distribution ratios are dense pores I, 1 / 64mm 2 , the distance between hollow cylinders and hollow cylinders is 8mm; loose pores II, 1 / 2500mm 2 , the distance between the hollow cylinder and the hollow cylinder is 50mm, and the other operating conditions are the same, the results obtained after pre-cooling are shown in Table 4 below:

[0062] Table 4 Effects of different devices (density distribution) assisted vacuum precooling methods on rice quality and process parameters

[0063]

[0064] Remarks: The data of texture and color difference are detected after refrigerated for 3 days. L*: means black and white, the larger the value, the whiter the colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com