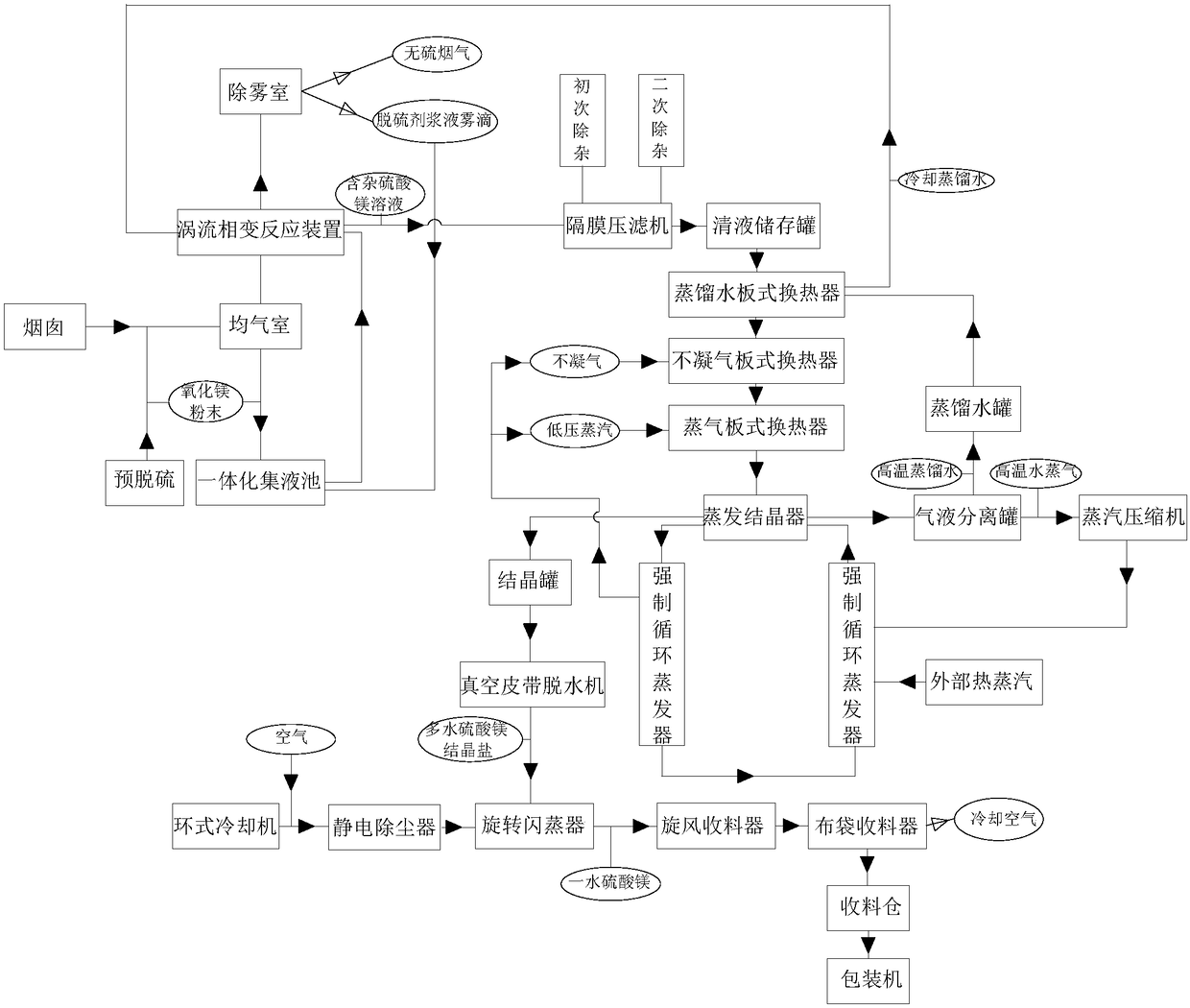

Liquid-vapor vortex phase-change integrated desulfurization and by-product recovery process

A by-product, eddy current technology, applied in magnesium sulfate, gas treatment, chemical instruments and methods, etc., can solve the problems of complex equipment, low reaction efficiency, high system energy consumption, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

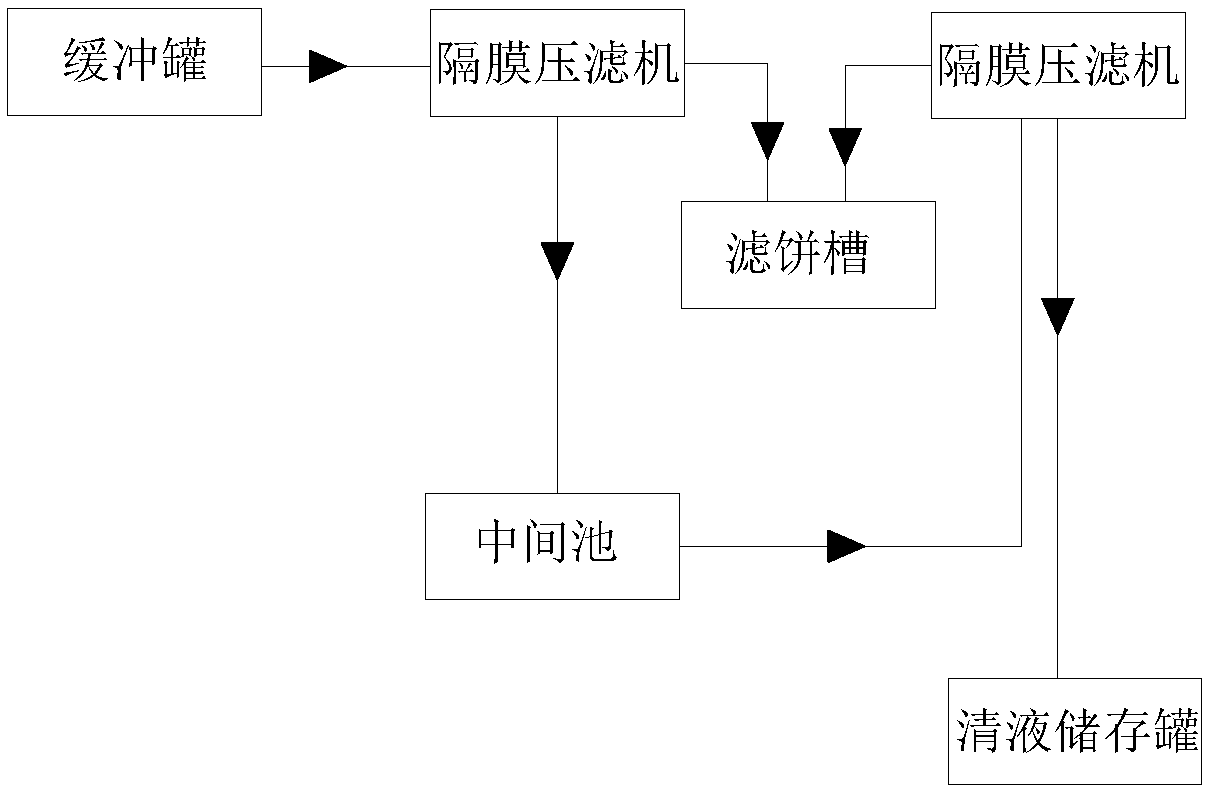

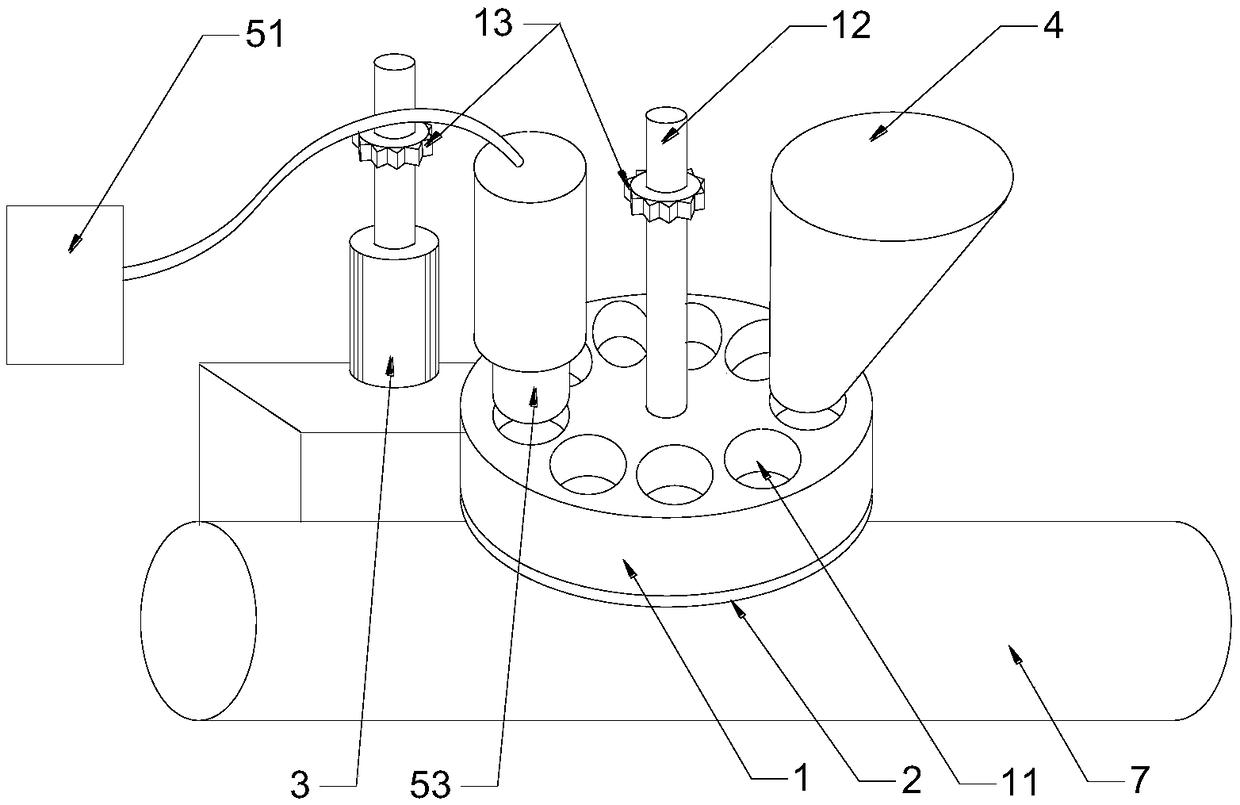

Method used

Image

Examples

Embodiment 1

[0087] SO in flue gas 2 The initial concentration is 2000mg / Nm 3 , according to S1-S11, S41-S42, S111-S114 for desulfurization and recovery of by-products, SO in flue gas discharged after desulfurization 2 The concentration is 45mg / Nm 3 , lower than the concentration of 160mg / Nm in Comparative Example 1 3 .

[0088] project

[0089] The consumption of magnesium oxide powder is 800 tons, and the consumption of electricity is 3.125x10 5 kWh, 5,650 tons of water, 920 tons of steam, and 840 tons of magnesium sulfate monohydrate powder as a by-product. Calculated at a market price of 2,400 yuan / ton, the profit is 2.016 million yuan, and the total annual cost is 5.179 million yuan. In the comparative example, a total of 2.2513 million yuan was saved.

Embodiment 2

[0091] Instead of using S1, the sulfur-containing flue gas is directly reacted with the desulfurizer slurry, and the other steps are the same, the results are as follows: SO in the flue gas 2 The initial concentration is 2000mg / Nm 3 , SO in flue gas discharged after desulfurization 2 The concentration is 65mg / Nm 3 , lower than the latest national emission standard 200mg / Nm 3 , the consumption of magnesium oxide powder is 800 tons, and the consumption of electricity is 3.125x10 5 kWh, 5,650 tons of water, 920 tons of steam, 840 tons of magnesium sulfate monohydrate powder as a by-product, 2.016 million yuan in profit, and 5.179 million yuan in annual expenses.

Embodiment 3

[0092] Embodiment 3: The impurity removal step in S4 is only carried out once, and other steps are the same as in Embodiment 1. The results are as follows: SO in the flue gas 2 The initial concentration is 2000mg / Nm 3 , SO in flue gas discharged after desulfurization 2 The concentration is 45mg / Nm 3 , the consumption of magnesium oxide powder is 800 tons, and the consumption of electricity is 3.125x10 5 kWh, 5,650 tons of water, 920 tons of steam, 800 tons of by-product magnesium sulfate monohydrate powder, 1.92 million yuan in profit, and 5.2752 million yuan in annual expenses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com