Optical fiber drawing tower control system

A control system and wire drawing tower technology, applied in manufacturing tools, glass manufacturing equipment, glass production, etc., can solve the problems of unstable die-piercing success rate and low die-piercing work efficiency, so as to facilitate maintenance and replacement, and save manpower and material resources. , the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

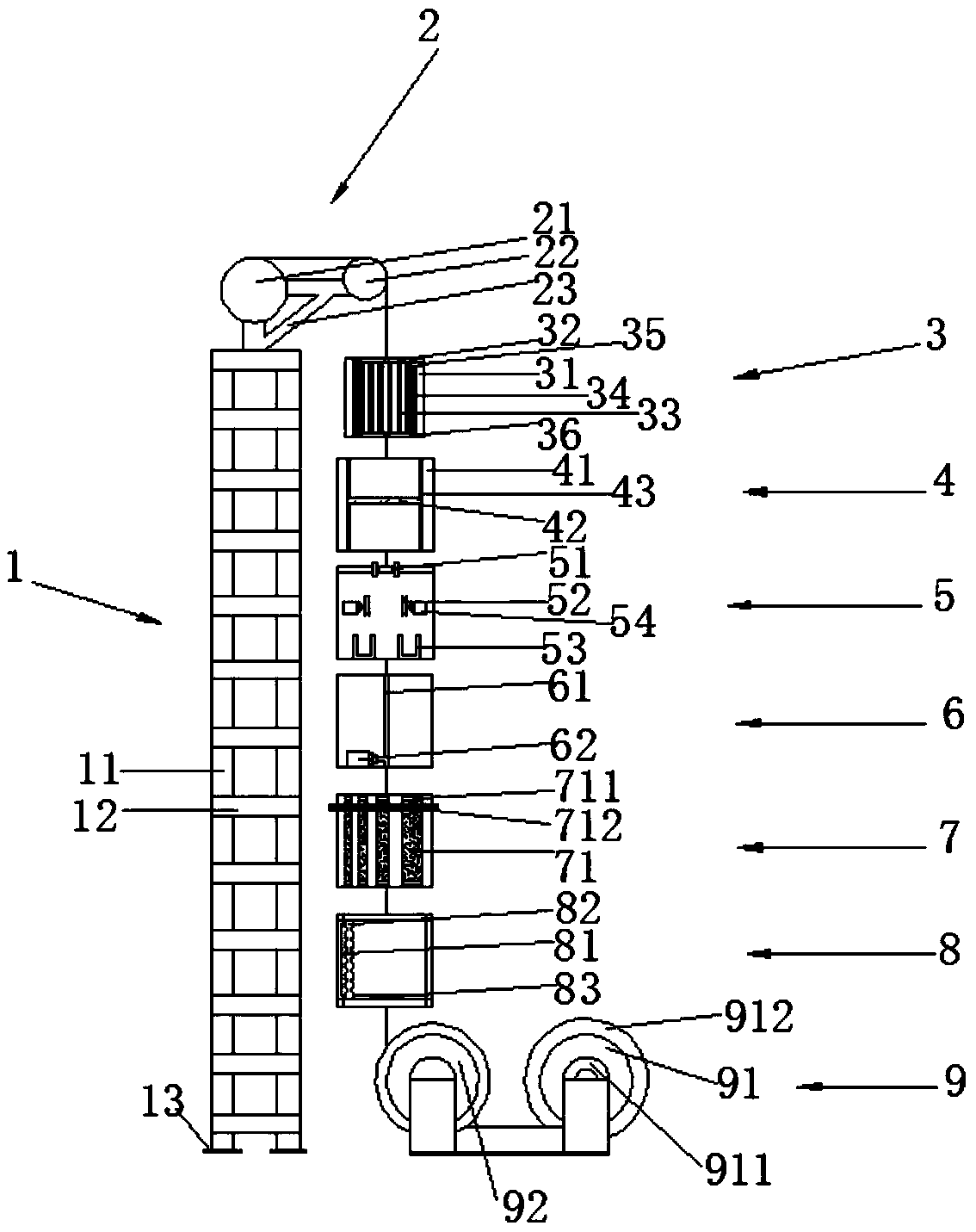

[0031] like figure 1 Shown: a control system for an optical fiber drawing tower, including a drawing tower 1, a preform core adjustment device 2, a heating furnace 3, a bare fiber diameter measuring instrument 4, a waste optical fiber collection device 5, a mold passing device 6, and a coating container 7 , curing furnace 8 and traction device 9; the wire drawing tower 1 is vertically arranged on the ground, the preform core adjustment device 2 is arranged on the top of the wire drawing tower, the heating furnace 3, the bare fiber diameter measuring instrument 4, the waste optical fiber The collecting device 5 , the mold passing device 6 , the coating container 7 , and the curing furnace 8 are sequentially installed on the side of the wire drawing tower 1 from top to bottom, and the traction device 9 is installed on the ground and connected with the curing furnace 8 .

[0032] like figure 1 As shown: the drawing tower 1 consists of four longitudinal steel pipes 11 and several...

Embodiment 2

[0037] like figure 1 Shown: a control system for an optical fiber drawing tower, including a drawing tower 1, a preform core adjustment device 2, a heating furnace 3, a bare fiber diameter measuring instrument 4, a waste optical fiber collection device 5, a mold passing device 6, and a coating container 7 , curing furnace 8 and traction device 9; the wire drawing tower 1 is vertically arranged on the ground, the preform core adjustment device 2 is arranged on the top of the wire drawing tower, the heating furnace 3, the bare fiber diameter measuring instrument 4, the waste optical fiber The collecting device 5 , the mold passing device 6 , the coating container 7 , and the curing furnace 8 are sequentially installed on the side of the wire drawing tower 1 from top to bottom, and the traction device 9 is installed on the ground and connected with the curing furnace 8 .

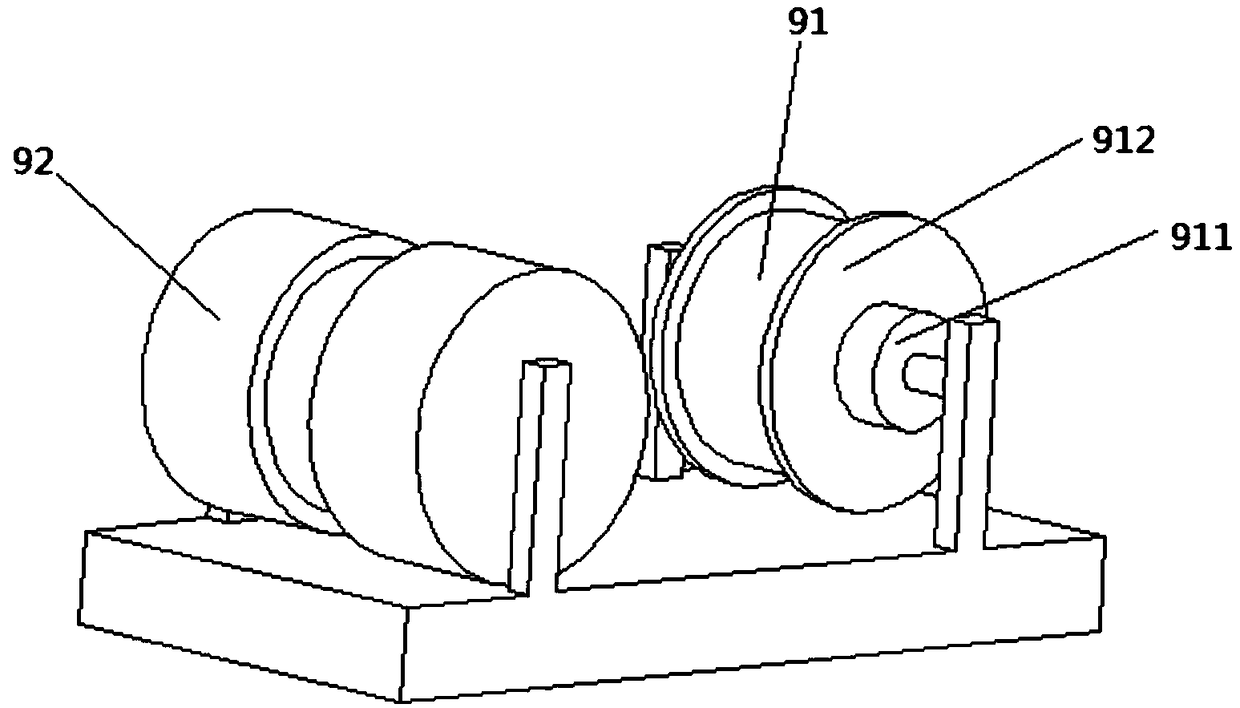

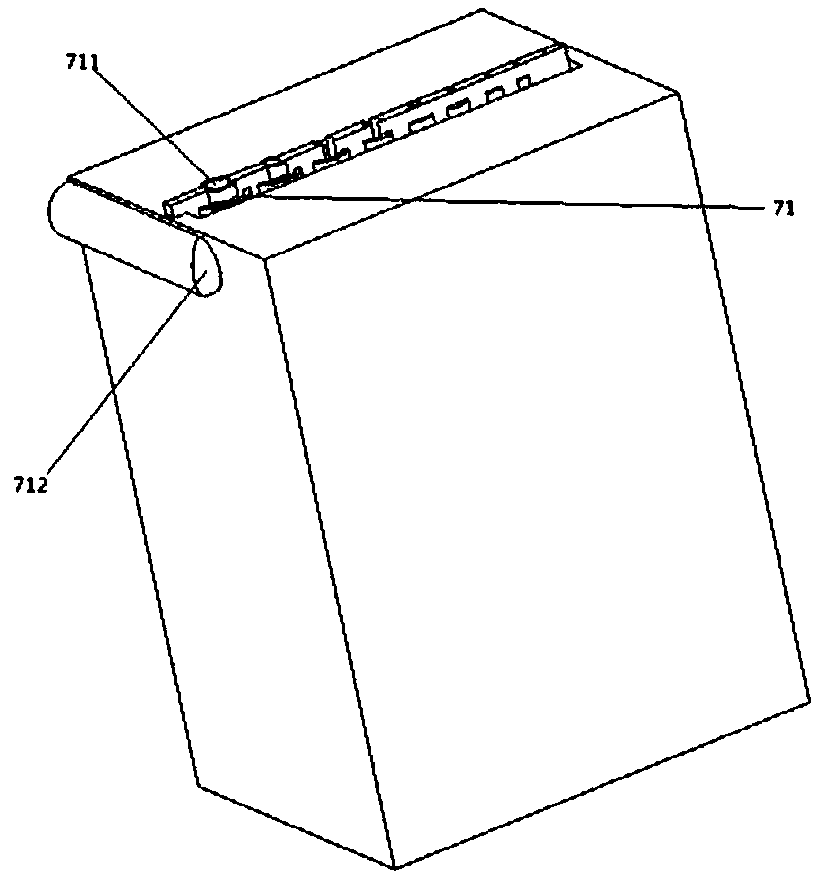

[0038] like figure 1 and Figure 4 As shown: the waste optical fiber collection device 5 is a drum structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com