Special ceramic metal glaze for ceramics

A technology of ceramic metal and ceramics, which is applied in applications, household appliances, and other household appliances, etc., can solve the problems of poor chemical stability, hardness, limited application range, and high price, and achieve chemical stability and increased hardness. Low price, The effect of lowering the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

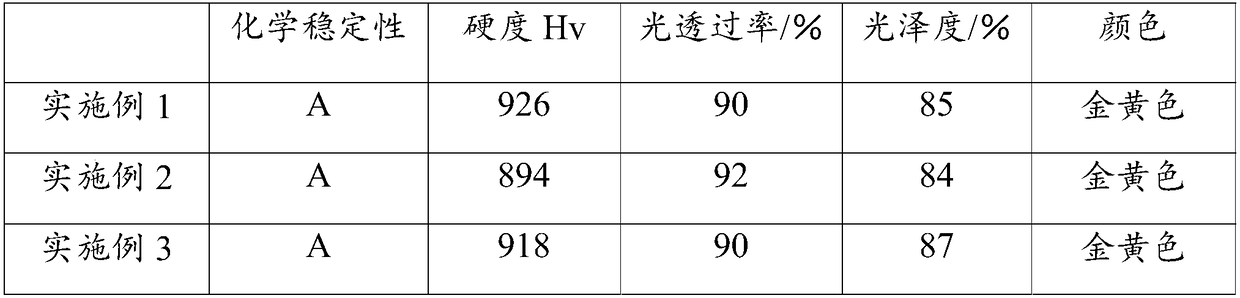

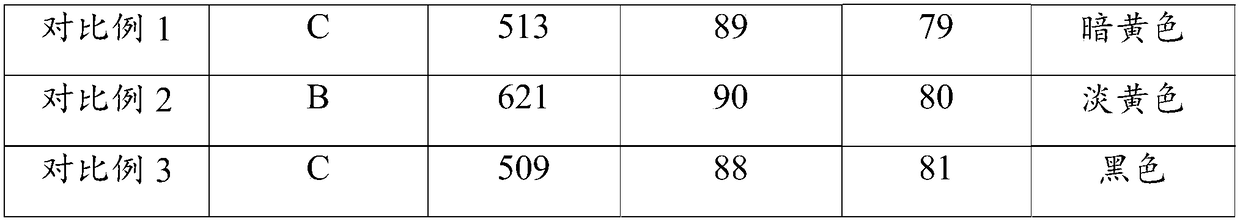

Examples

Embodiment 1

[0016] A special ceramic metal glaze for ceramics provided in this embodiment is made of the following raw material components in parts by weight: 28 parts of potassium feldspar, 22 parts of china clay, 20 parts of copper oxide, 9 parts of silicon carbide, 7 parts of boric acid, titanium dioxide 6 servings.

[0017] The preparation method of above-mentioned ceramic metal glaze, comprises the following steps:

[0018] S1. Weigh each raw material component according to the weight ratio;

[0019] S2. Pour each raw material component into a ball mill and mix evenly, then add ball milling medium and water, raw material: ball milling medium: water weight ratio = 1:1.8:0.7; ball milling for 20 minutes;

[0020] S3, after the ball milling, measure the fineness of the glaze slurry, the fineness of the glaze slurry is controlled at 325 mesh sieve: 0.12%;

[0021] S4. Take the prepared ceramic body, apply glaze on the surface of the ceramic body, then place the glazed ceramic body in a...

Embodiment 2

[0023] A special ceramic metal glaze for ceramics provided in this embodiment is made of the following raw material components in parts by weight: 32 parts of potassium feldspar, 20 parts of china clay, 15 parts of copper oxide , 11 parts of silicon carbide, 7 parts of boric acid, 5 parts of titanium dioxide;

[0024] The preparation method of above-mentioned ceramic metal glaze, comprises the following steps:

[0025] S1. Weigh each raw material component according to the weight ratio;

[0026] S2. Pour each raw material component into a ball mill and mix evenly, then add ball milling medium and water, raw material: ball milling medium: water weight ratio = 1:1.8:0.6; ball milling for 15 minutes;

[0027] S3, after the ball milling, measure the fineness of the glaze slurry, the fineness of the glaze slurry is controlled at 325 mesh sieve: 0.10%;

[0028] S4. Take the prepared ceramic body, apply glaze on the surface of the ceramic body, then place the glazed ceramic body in...

Embodiment 3

[0030] A special ceramic metal glaze for ceramics provided in this embodiment is made of the following raw material components in parts by weight: 20 parts of potassium feldspar, 24 parts of china clay, 17 parts of copper oxide , 9 parts of silicon carbide, 7 parts of boric acid, 6 parts of titanium dioxide;

[0031] S1. Weigh each raw material component according to the weight ratio;

[0032] S2. Pour each raw material component into a ball mill and mix evenly, then add ball milling medium and water, raw material: ball milling medium: water weight ratio = 1:1.5:0.8; ball milling 17min;

[0033] S3, after the ball milling, measure the fineness of the glaze slurry, the fineness of the glaze slurry is controlled at 325 mesh sieve: 0.08%;

[0034] S4. Take the prepared ceramic body, apply glaze on the surface of the ceramic body, then place the glazed ceramic body in a roller kiln, heat up to 720° C., keep it warm for 18 minutes, and form a metallic glaze on the surface of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com