Isocyanate modified urea-formaldehyde resin adhesive and preparation method thereof

A urea-formaldehyde resin glue, isocyanate technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of affecting the modification effect and use, the difficulty of dispersing isocyanates, and the short storage period of urea-formaldehyde resins, etc. The problem is to shorten the hot pressing time, improve the water resistance, and the reaction conditions are easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of isocyanate modified urea-formaldehyde resin adhesive includes the following steps:

[0042] S1. The sealing agent is added to the urea-formaldehyde resin under stirring conditions, and the urea-formaldehyde resin solution is obtained after uniform mixing;

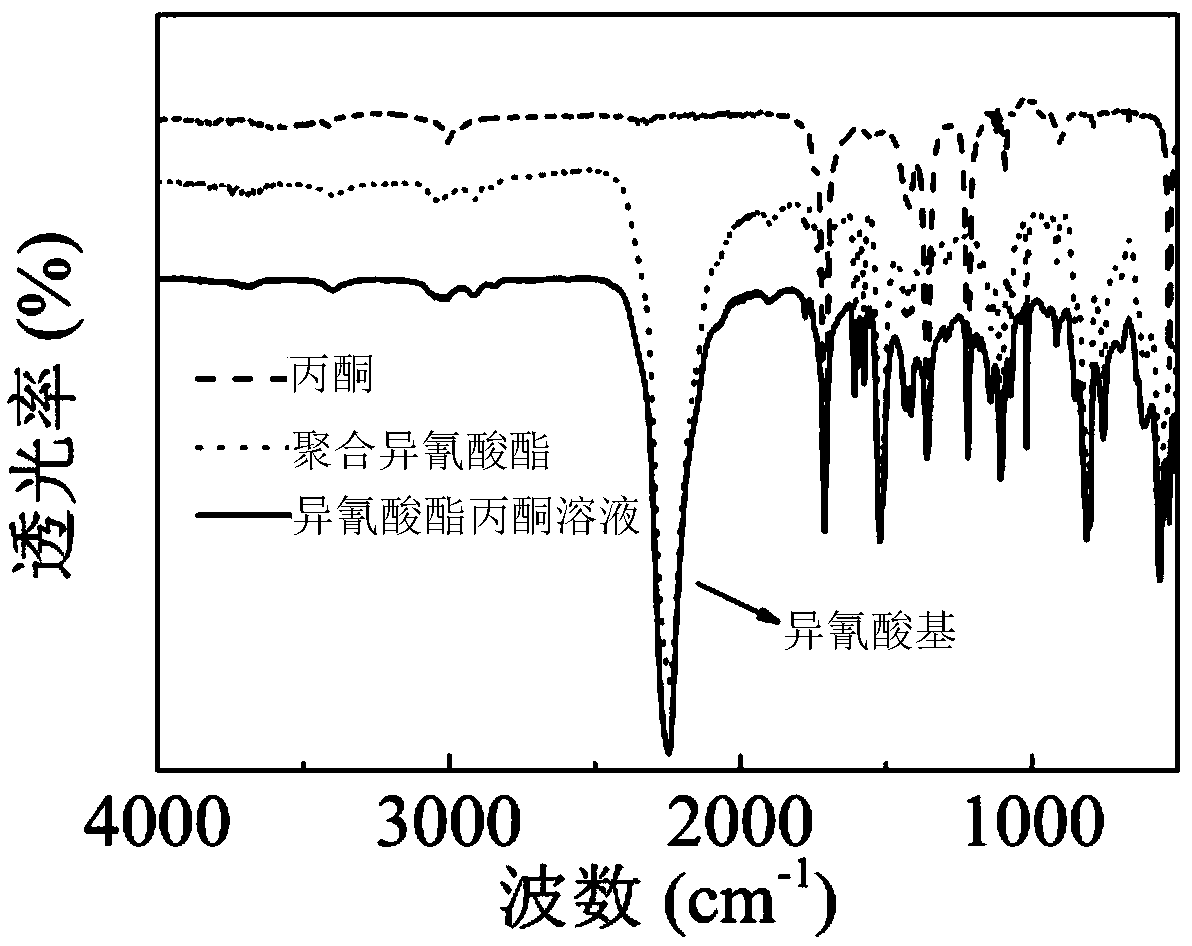

[0043] S2. The isocyanate is added to the solvent under vacuum, and the isocyanate solution is obtained after uniform mixing;

[0044] S3. Add the isocyanate solution obtained in step S2 to the urea-formaldehyde resin solution obtained in step S1 under stirring conditions, and mix uniformly to obtain an adhesive.

[0045] The preparation method of the invention has simple steps, easy reaction conditions to realize, and can be prepared in a large amount without subsequent special treatment processes, reaction conditions are easy to control, low cost, clean and pollution-free.

Embodiment 1

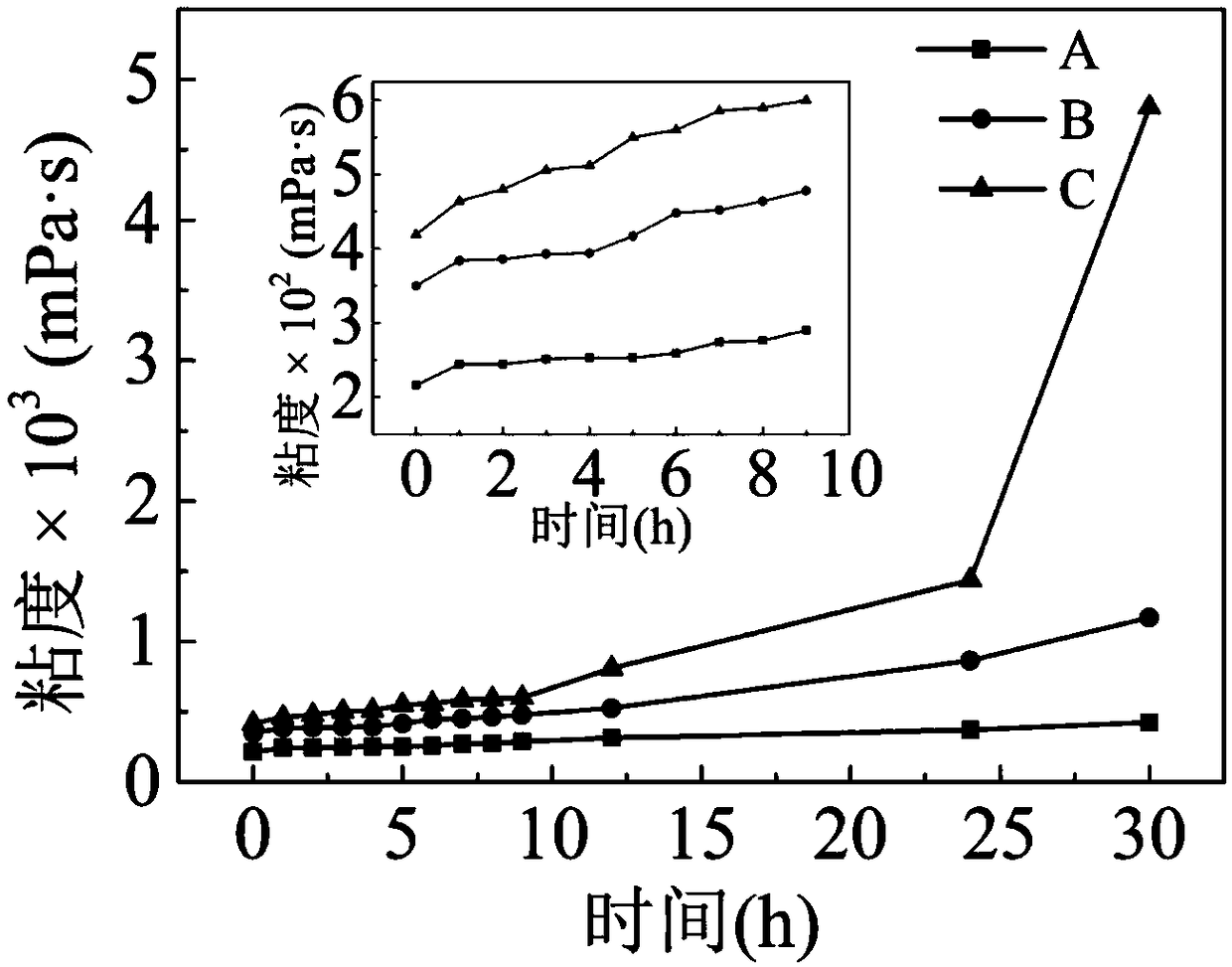

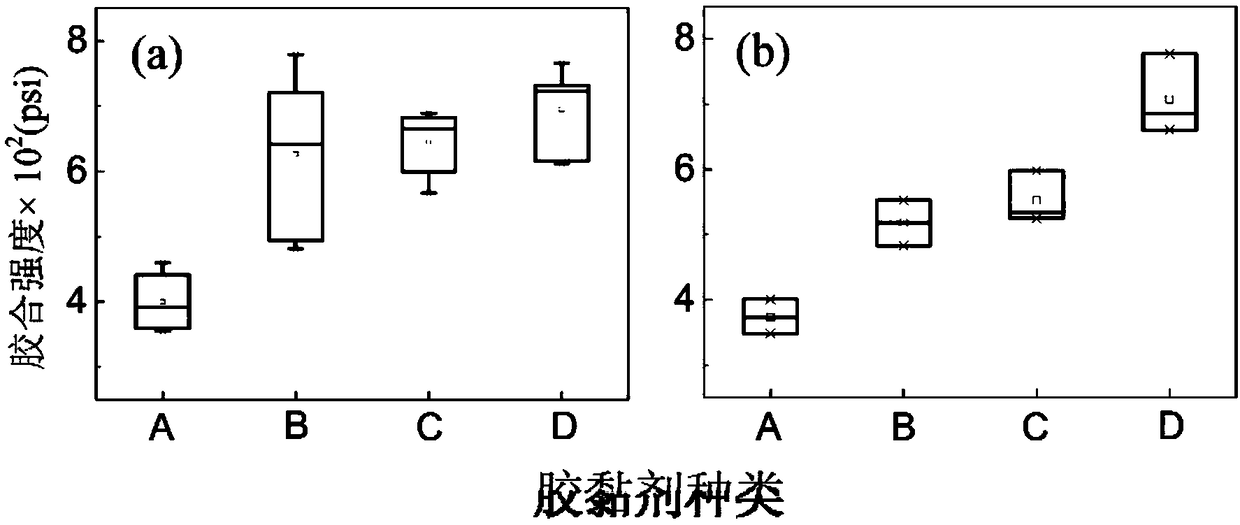

[0047] An isocyanate modified urea-formaldehyde resin adhesive of the present invention, wherein the isocyanate content is 15% (adhesive solid content).

[0048] The preparation method of the isocyanate modified urea-formaldehyde resin adhesive of this embodiment includes the following steps:

[0049] (1) Weigh the raw materials according to the percentage of parts by mass, 22g of polymerized isocyanate, 200g of urea-formaldehyde resin, 12g of sodium bisulfite, 10g of acetone, viscosity of polymerized isocyanate of 160mPa·s, and mass fraction of isocyanate group (-NCO): 28%; urea-formaldehyde resin viscosity is 180mPa·s, solid content is 65%; acetone concentration is analytically pure.

[0050] (2) Add sodium bisulfite to the urea-formaldehyde resin at room temperature. Stir the urea-formaldehyde resin continuously during the adding process to dissolve and disperse the sodium bisulfite evenly in the urea-formaldehyde resin. After the sodium bisulfite is added, continue Stir and stir...

Embodiment 2

[0062] An isocyanate modified urea-formaldehyde resin adhesive of the present invention, wherein the isocyanate content is 10% (solid content of the adhesive).

[0063] The preparation method of the isocyanate modified urea-formaldehyde resin adhesive of this embodiment includes the following steps:

[0064] (1) Weigh the raw materials according to the percentage by mass, polymer isocyanate 14g, urea-formaldehyde resin 200g, sodium bisulfite 10g, acetone 6g, polymer isocyanate viscosity 180mPa·s, and the mass fraction of isocyanate group (-NCO) is 30%; urea-formaldehyde resin viscosity is 200mPa·s, solid content is 65%; sodium sulfite and acetone concentrations are both analytically pure.

[0065] (2) Add sodium bisulfite to the urea-formaldehyde resin at room temperature. Stir the urea-formaldehyde resin continuously during the adding process to dissolve and disperse the sodium bisulfite evenly in the urea-formaldehyde resin. After the sodium bisulfite is added, continue Stir and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com