Method for electrolytic deposition of WO3 thin film on non-continuous conducting film

A technology of conductive film and electrodeposition, which is applied in the direction of non-woven fabrics, plating of superimposed layers, electrolytic inorganic material plating, etc., can solve the problems of high cost of preparation methods, achieve low cost, large control window, and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

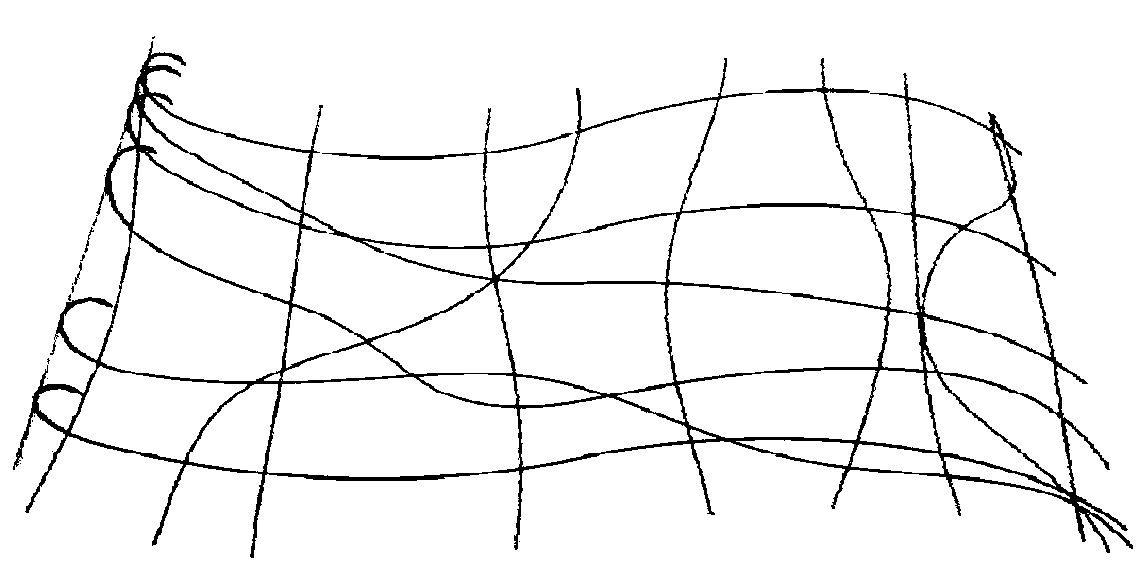

[0042] (1) figure 1 It is a schematic structural diagram of the W / Ag NTs / W / PET transparent conductive film of the present invention. Cut a commercially available PET (or other flexible substrate) flexible film (light transmittance ~ 95%) with a thickness of 100 μm into small rectangular pieces, and ultrasonically clean the PET surface with ethanol and water respectively, and use it as a substrate for future use. Then fix it in the chamber of the magnetron sputtering instrument, pass in argon gas, set the sputtering parameters as pressure 4-6Pa, power 60-100W, sputtering time 1-10min for WO 3 Sputtering of the base layer.

[0043] (2) PVA nanofibers were prepared by electrospinning, and the grooves made of thick aluminum foil were used as PVA spinning receivers. The PVA solution is used as the spinning ink, and the spinning is carried out perpendicular to the groove in an electric field with a positive voltage of 10-15kV and a negative voltage of 0-2kV. The obtained nanofibe...

Embodiment 2

[0048] Step (1), (2) are identical with embodiment 1.

[0049] (3) H with a ratio of 1:4:50 2 o 2 : HClO 4 : DI water is added into the beaker and mixed to obtain the deposition solution. Put the conductive substrate obtained in step (3) into the deposition solution, and set the parameters on the electrochemical workstation to deposit WO 3 , the pulse voltage of each cycle is: -1V, 0.1s, 0V, 0.5s and the cycle interval of 1.1 ~ 1.5s. Set the total deposition time to 1.5 h. From Figure 7 It can be seen that as the deposition time increases, the discoloration window of the film increases to 80.6%.

[0050] (4) This step is the same as step (4) in Example 1.

[0051] The discoloration window test curve of the sample prepared in the embodiment of the present invention 2 sees Figure 6 .

Embodiment 3

[0053] Steps (1) and (2) are the same as in Example 1.

[0054] (3) H with a ratio of 1:4:50 2 o 2 : HClO 4 : DI water is added into the beaker and mixed to obtain the deposition solution. Put the conductive substrate obtained in step (3) into the deposition solution, and set the parameters on the electrochemical workstation to deposit WO 3 , the pulse voltage of each cycle is: -1V, 0.1s, 0V, 0.5s and the cycle interval of 1.1 ~ 1.5s. Set the total deposition time to 2h. From Figure 8 It can be seen that as the deposition time increases, the film thickness increases, and the discoloration window of the film increases to 89.7%.

[0055] (4) This step is the same as step (4) in Example 1.

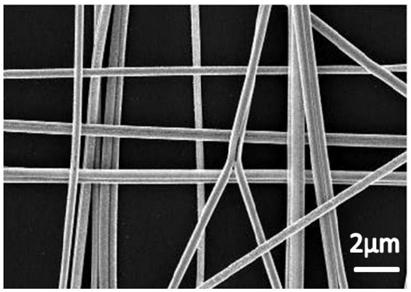

[0056] The discoloration window test curve of the sample prepared in the embodiment of the present invention 3 sees Figure 7 , the SEM of the different magnifications of the sample prepared in the embodiment of the present invention 3 sees Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com