Two-dimensional bismuth oxygen selenium atom crystal materials and preparation method and application thereof

A crystal material, bismuth oxide technology, applied in the field of two-dimensional materials, can solve the problem that the ratio of bismuth source and selenium source is not easy to control, and achieve the effect of large area growth, low preparation cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of a two-dimensional bismuth oxyselenide atomic crystal material comprises the following steps:

[0065] Bi 2 o 2 Se powder is placed in the upstream end area of the airflow direction of the horizontal tube furnace, and the mica substrate is placed in the downstream end area of the reaction furnace in the airflow direction, Bi 2 o 2 The distance between the Se powder and the mica substrate is 6 cm, and the temperature rises to 620 °C at a rate of 30 °C / min in a nitrogen gas environment. 2 o 2 The Se powder was heat-treated for 25 minutes. After the heat treatment, the reaction system was naturally cooled to 25°C under the condition of a nitrogen gas flow rate of 200 sccm, and the test results of the two-dimensional bismuth oxygen selenium atomic crystal material were as follows: Figure 1-12 shown.

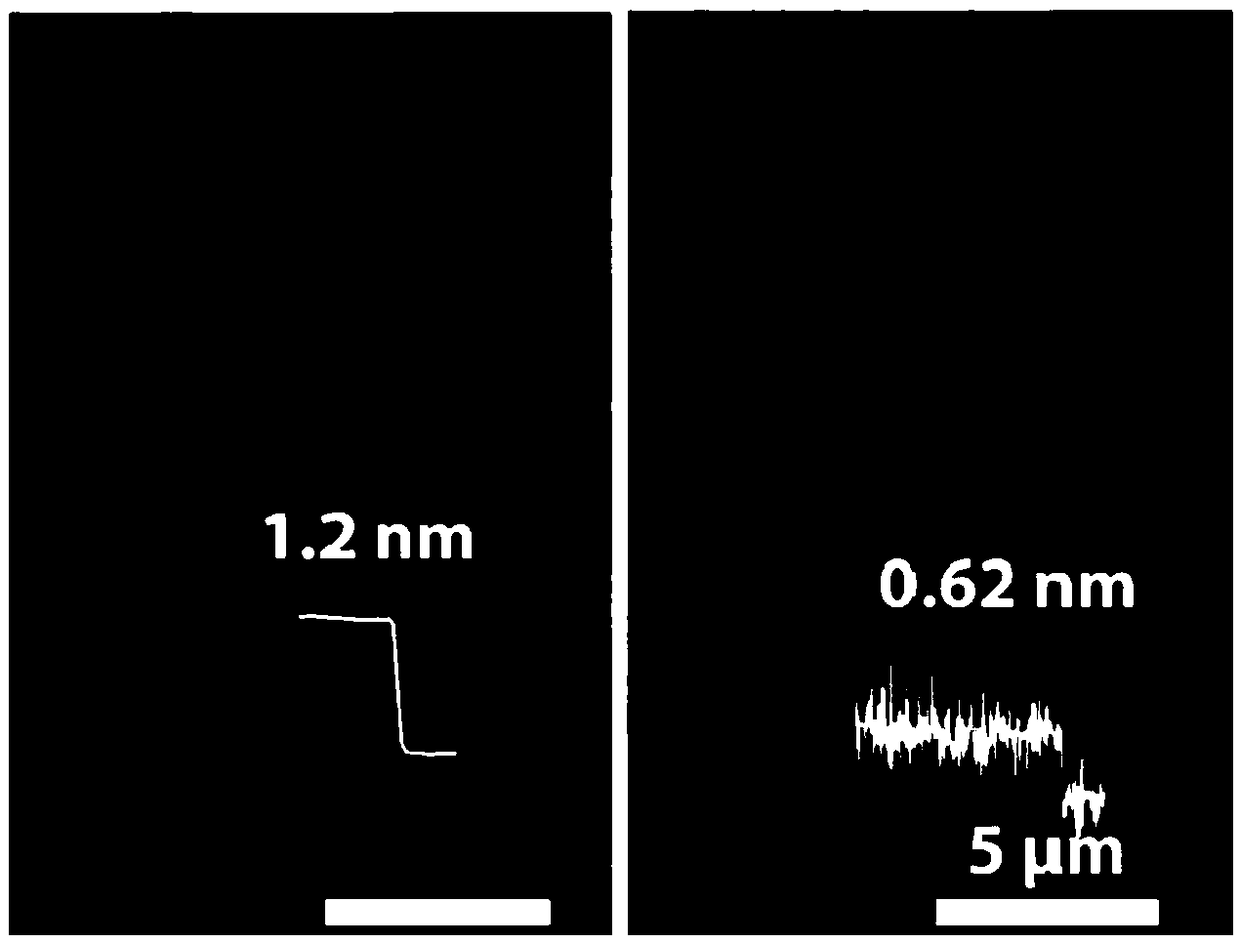

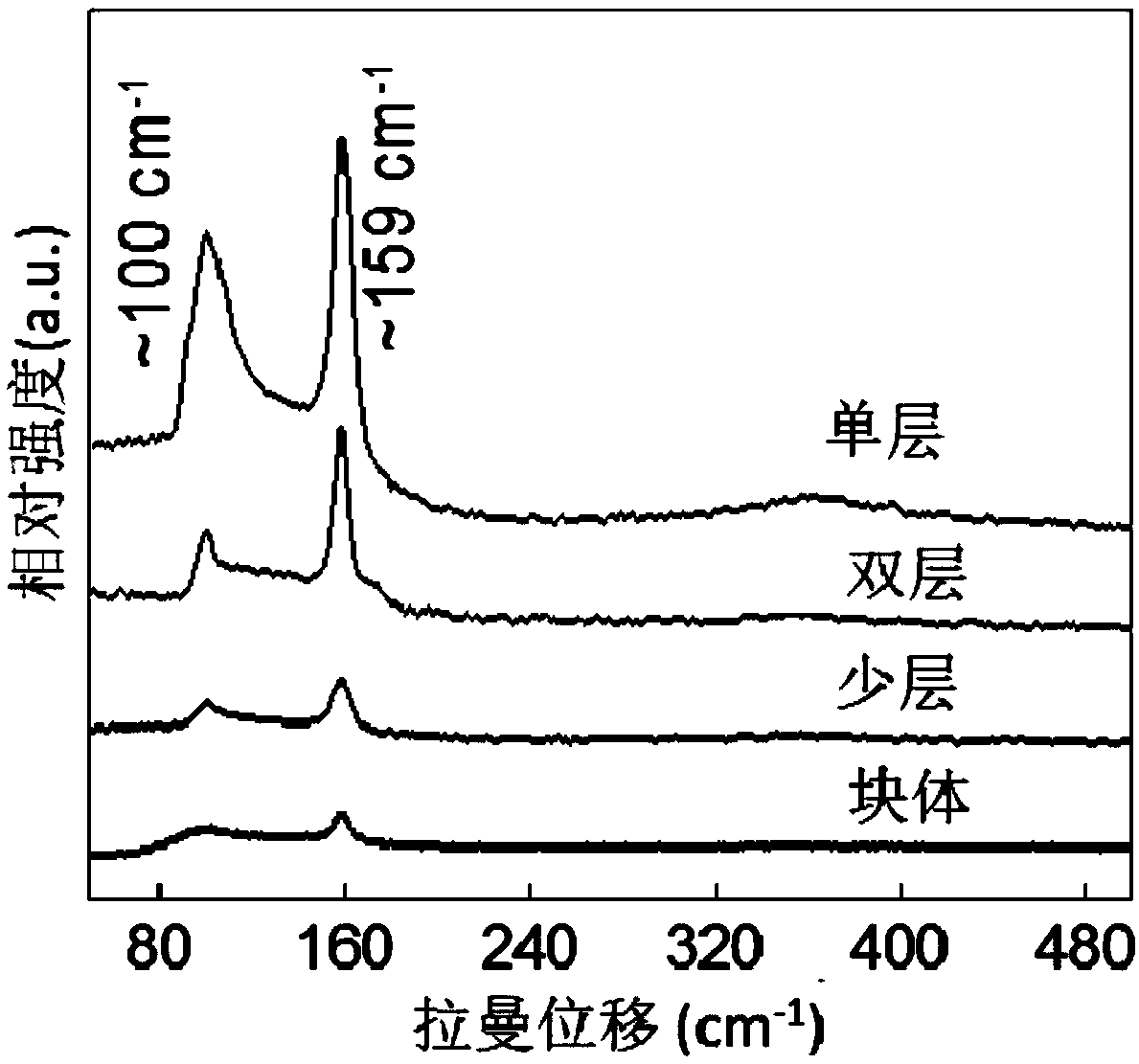

[0066] figure 1 a, 1b are optical microscope pictures of the two-dimensional bismuth oxygen selenium atomic crystal material prepared by fig...

Embodiment 2

[0079] The difference from Example 1 is that the heat treatment temperature is 580°C.

Embodiment 3

[0081] The difference from Example 1 is that the heat treatment temperature is 800°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com