Temperature rise test system and method for photovoltaic inverter in field operation condition

A photovoltaic inverter and on-site operation technology, applied in signal transmission systems, instruments, thermometers, etc., can solve the problems of difficult wiring, poor expandability, easy to break, etc., and achieve the effect of convenient and flexible installation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

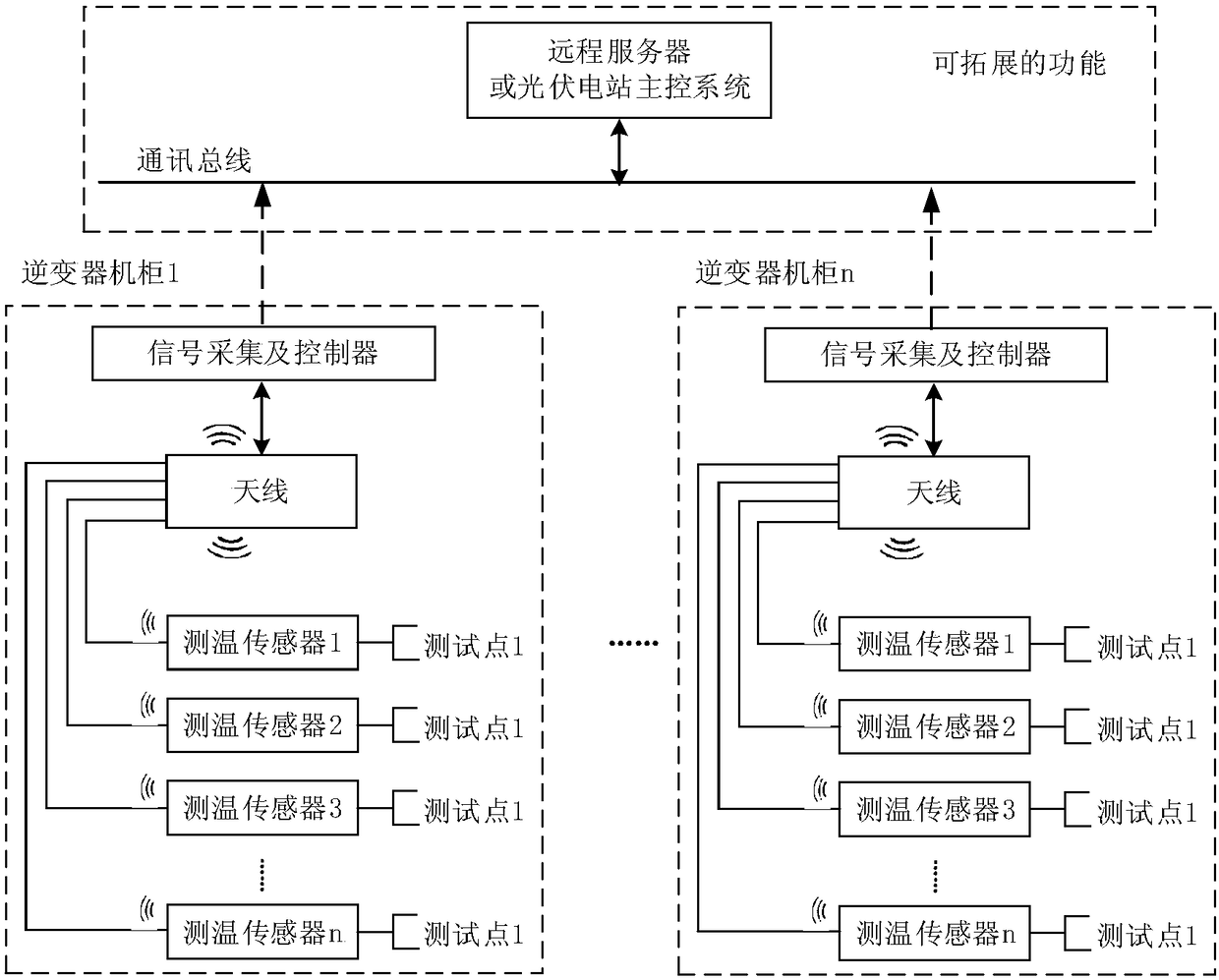

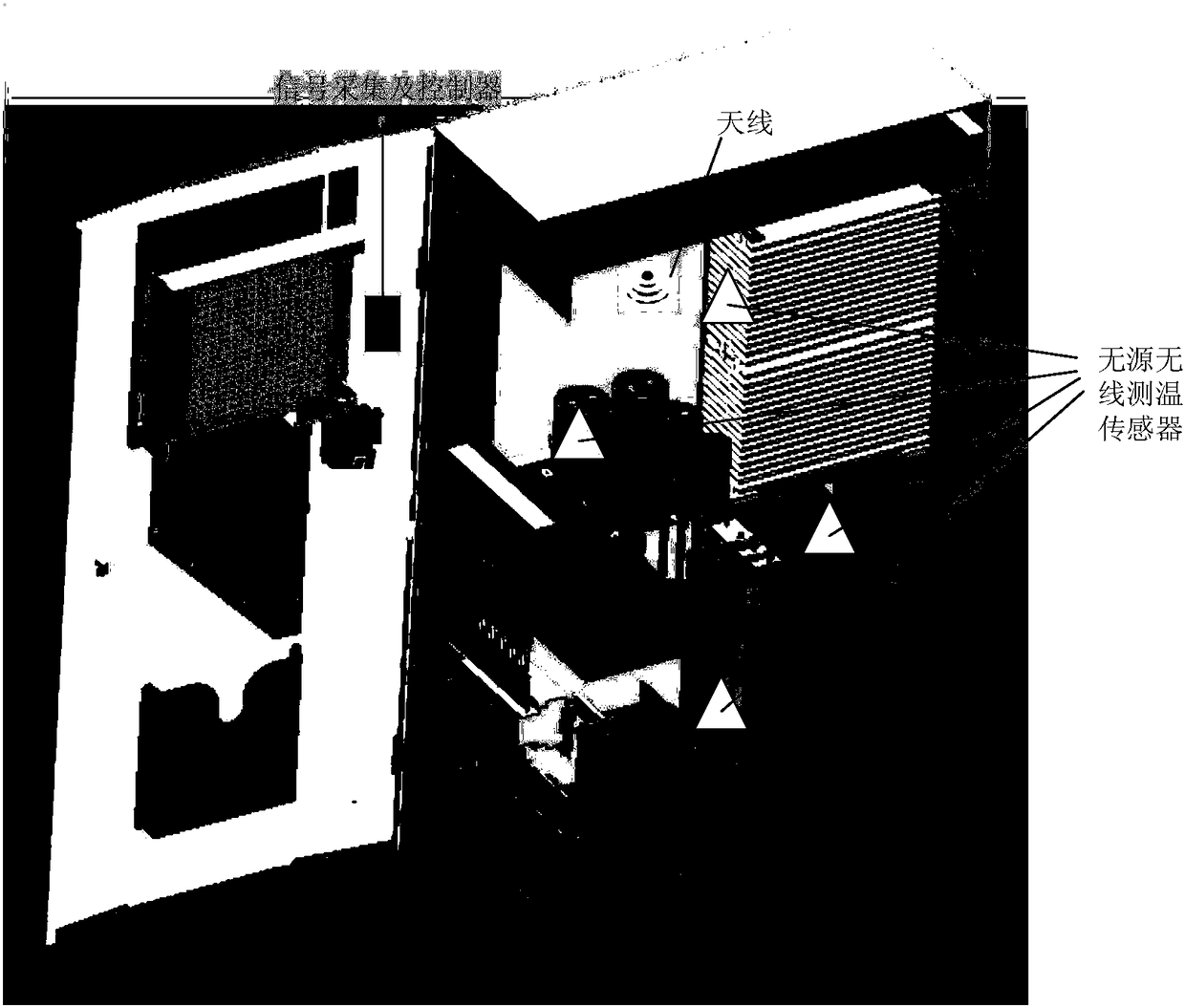

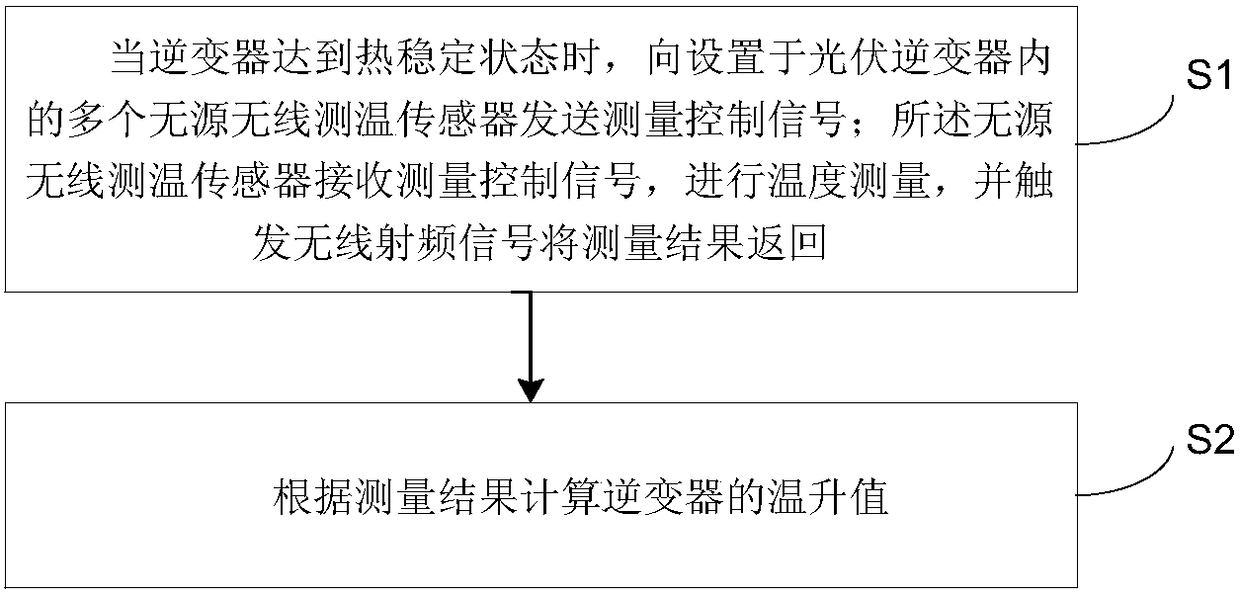

[0033] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] In order to solve the following deficiencies in the prior art:

[0035] 1) When the inverter is running normally, the cabinet must be closed, and the traditional active and wired test methods, infrared thermal imager temperature measurement method, etc. cannot be applied;

[0036] 2) The measurement sensor of the optical fiber temperature measurement method is not convenient to install in the narrow space in the inverter cabinet;

[0037] 3) Due to the limitation of irradiation resources, the photovoltaic inverter often cannot reach the rated output power during normal operation, and the temperature rise under the rated output power of the inverter cannot be tested.

[0038] In summary, conventional thermocouples, thermal resistors, semiconductor temperature sensors and other temperature measurement methods are difficult to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com