Soldering tin alloy for electronic part bonding electrodes and soldering method

A technology for electronic parts and electrodes, applied in the field of solder alloys and soldering, can solve the problems of poor tensile properties and thermal fatigue properties, coarse structure, cracks, etc., to improve mechanical strength and thermal fatigue properties. , to achieve the effect of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

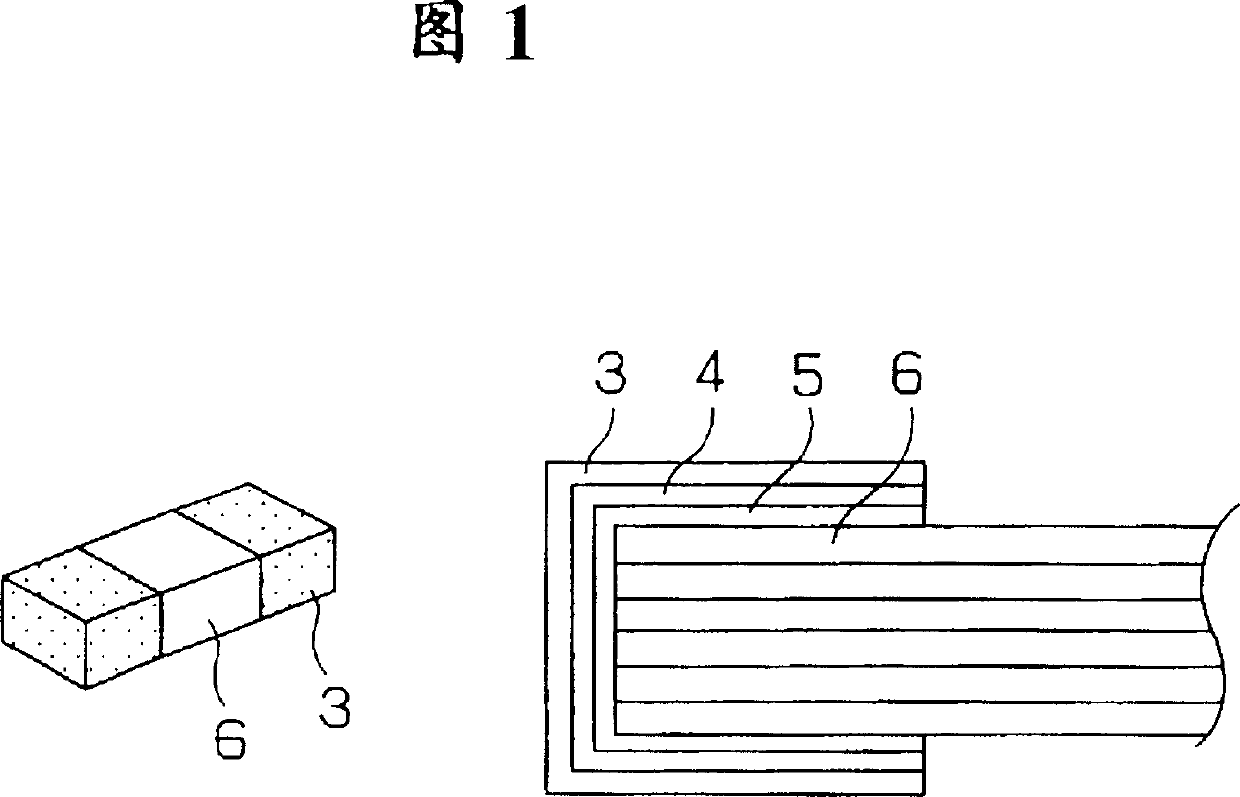

[0034] The solder alloy of Example 1 is a three-component solder alloy of Sn 94.5% by weight, Ag 5.0% by weight, and Cu 0.5% by weight.

[0035] The solder alloy was prepared into a paste solder with RMA flux for atmospheric air, and then the melting point, wettability, joint strength, thermal shock and other tests were carried out. The results are shown in Table 1. Although not described in Table 1, the The result of the tensile strength test of this solder was 8.3kgf / mm 2 , the same test result as Comparative Example 2 6.5kgf / mm 2 In contrast, the tensile strength is significantly improved.

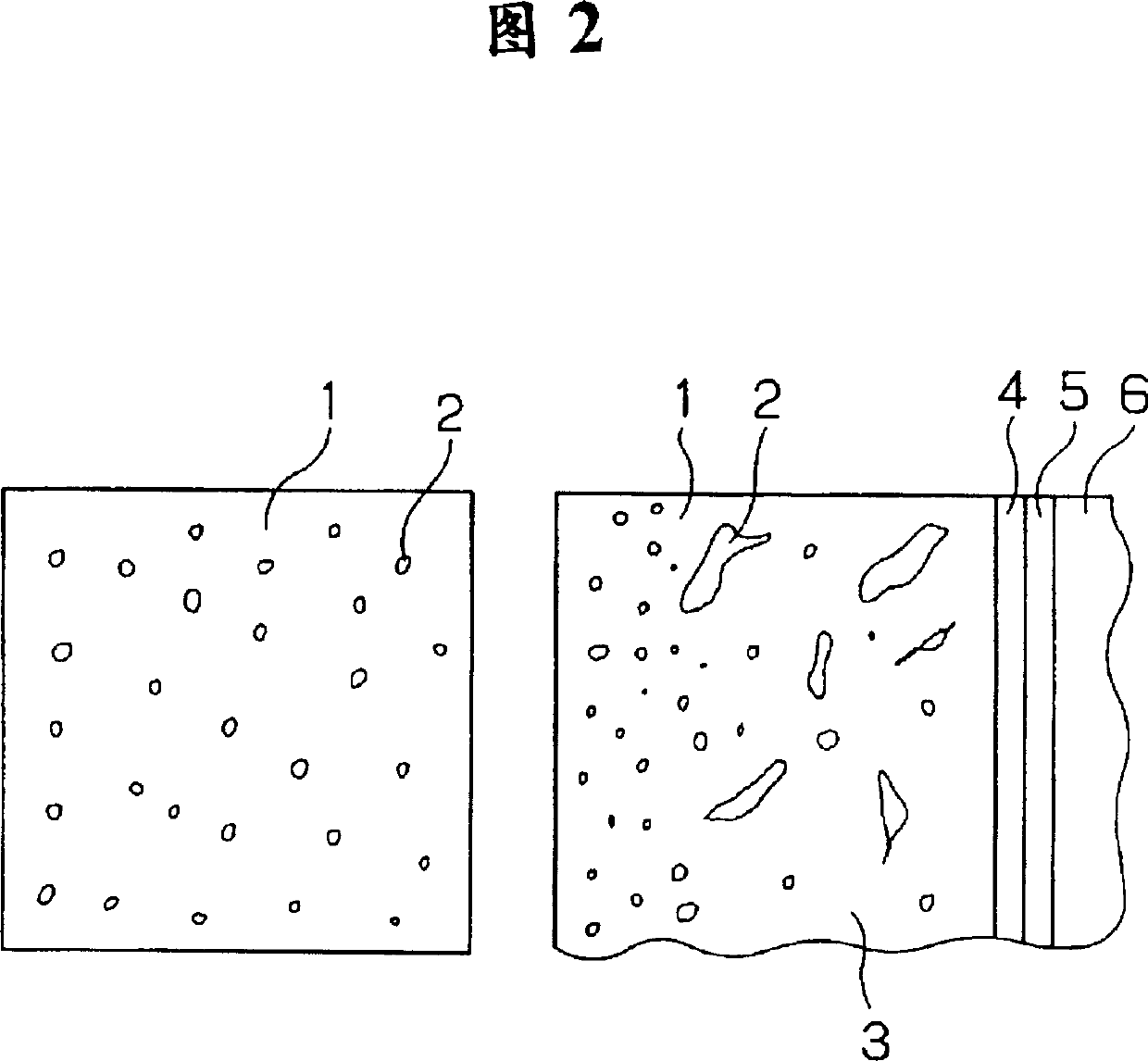

[0036] In addition, during the solidification process during soldering, rapid cooling and solidification of the solder can suppress intermetallic compounds (Ag 3 The growth of Sn) makes it into a fine and dispersed state, which is expected to improve its mechanical strength and improve thermal fatigue properties. The above-mentioned α solid solution and β solid solution can also achie...

Embodiment 2

[0038] The solder alloy of Example 2 is a five-component solder alloy of Sn 89.5% by weight, Ag 3% by weight, Bi 5% by weight, Cu 1.5% by weight, and In 1% by weight.

[0039] The results of each test are shown in Table 1, which clearly shows that, compared with Example 1, it can achieve a lowering of the melting point and an increase in the bonding strength.

[0040] The solder alloy of Example 2 was also subjected to rapid cooling and solidification of the solder at the time of soldering. As a result, the mechanical strength was improved and the thermal fatigue resistance was improved as in Example 1.

[0041] As the means of rapid cooling and solidification, as described in Example 1, the method of blowing cold air is preferable, and the cooling rate is 5-15°C / sec, especially about 10°C / sec.

[0042] Ag is solidified by quenching 3 Sn, Cu 3 Sn and Cu 6 Sn 5The resulting metal oxides are refined and dispersed, which can improve mechanical strength and thermal fatigue res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com