Electrolyte, preparation method and application of electrolyte, lithium ion battery and application of lithium ion battery

A technology of electrolyte and lithium salt, applied in the field of electrolyte, can solve the problems of increasing the internal resistance of the battery, shortening the service life of the battery, and destroying the cycle performance, and achieves the effect of improving the cycle performance, reducing the dissolution, and inhibiting the oxidative decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] According to the second aspect of the present invention, there is provided a method for preparing the above electrolytic solution, comprising the following steps: dissolving the inorganic conductive lithium salt in a solvent, and then adding additives to obtain the electrolytic solution;

[0058] In the invention, the electrolytic solution can be obtained by dissolving the inorganic conductive lithium salt and the additive in the solvent. The process is simple, easy to operate, easy to implement, no special restrictions on the environment, site, equipment, etc., low requirements on equipment, low investment cost, strong practicability and adaptability, is a simple, easy to control, environment-friendly, The low-cost electrolyte preparation method can realize high-volume production at low cost, and is easy to popularize and apply.

[0059] As a preferred embodiment, the temperature at which the inorganic conductive lithium salt is dissolved in the solvent is 20-40° C., t...

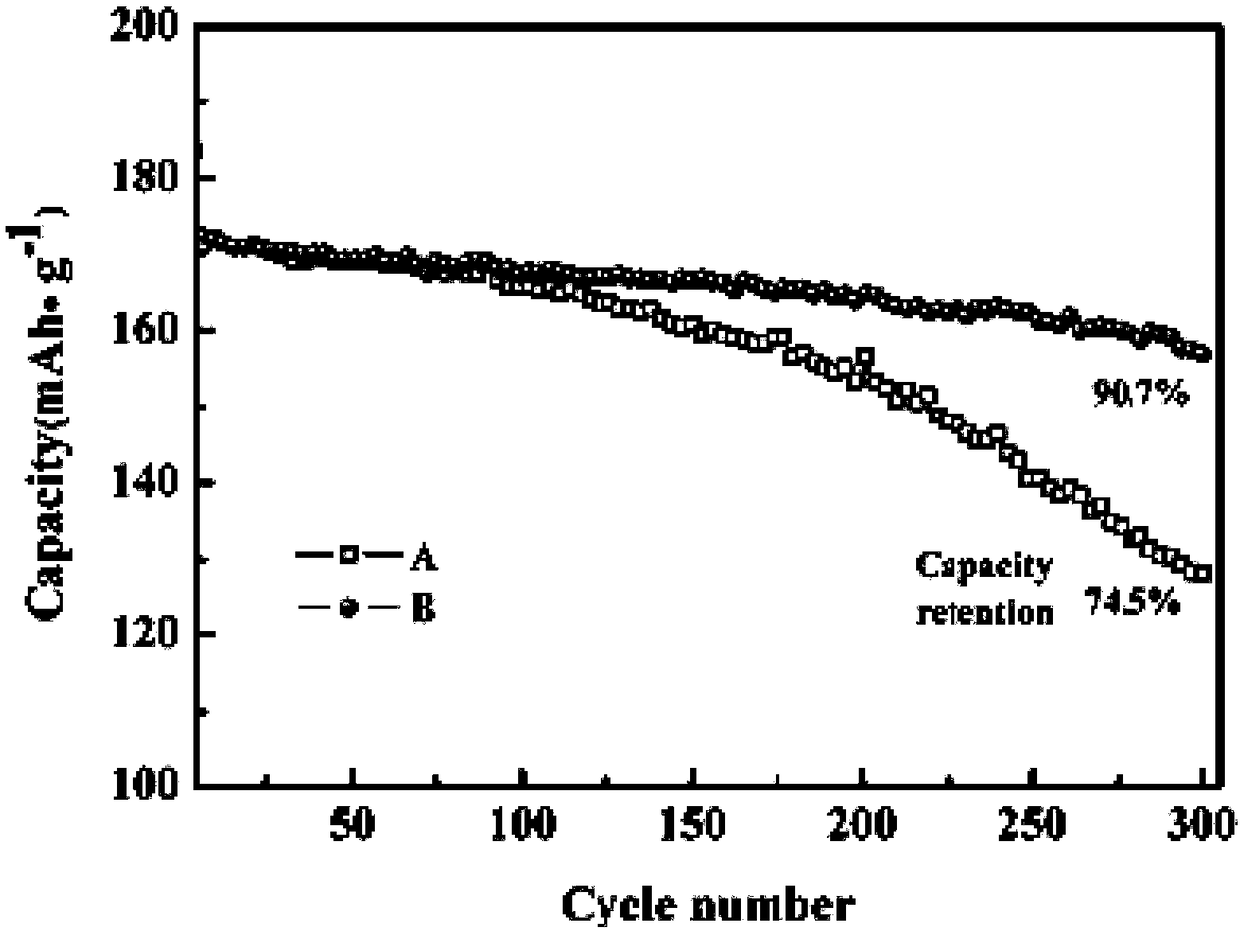

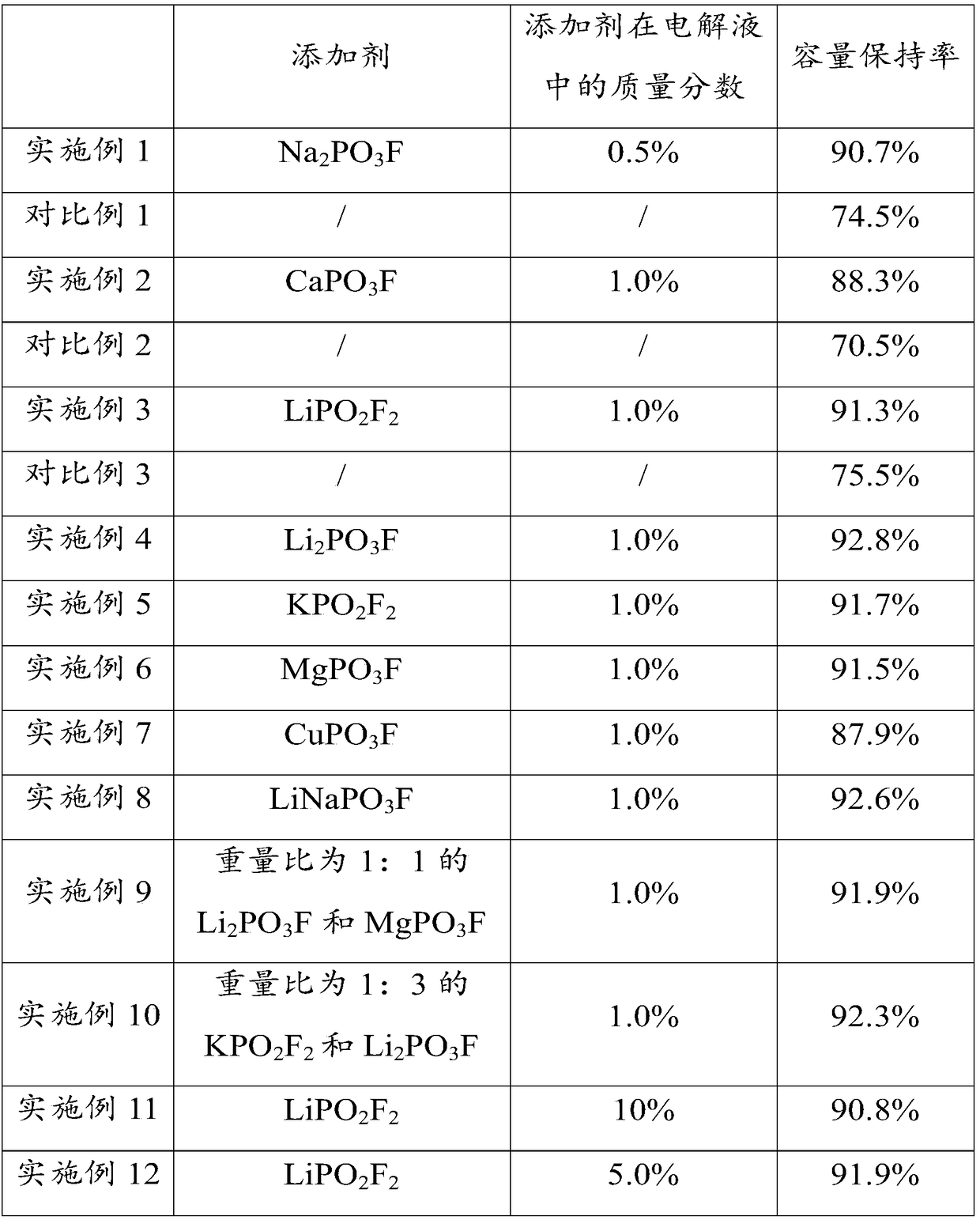

Embodiment 1

[0074] 1. An electrolyte comprising additives, inorganic conductive lithium salts and solvents.

[0075] The additive is fluorine-containing phosphate, the chemical formula is Na 2 PO 3 F, the mass fraction of additives in the electrolyte is 0.5%.

[0076] Inorganic conductive lithium salt is LiPF 6 , the concentration of the inorganic conductive lithium salt in the electrolyte is 1mol / L.

[0077] The solvents were ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) in a volume ratio of 1:1:1.

[0078] 2. A method for preparing an electrolyte, comprising the following steps: dissolving an inorganic conductive lithium salt in a solvent, and then adding additives to obtain an electrolyte;

[0079] Specifically:

[0080] (1) Mix ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) in a volume ratio of 1:1:1 in an argon-containing glove box, and remove them with molecular sieves and lithium hydride. Water removes imp...

Embodiment 2

[0088] 1. An electrolyte comprising additives, inorganic conductive lithium salts and solvents.

[0089] The additive is fluorine-containing phosphate, the chemical formula is CaPO 3 F, the mass fraction of additives in the electrolyte is 1.0%.

[0090] Inorganic conductive lithium salt is LiPF 6 , the concentration of the inorganic conductive lithium salt in the electrolyte is 1mol / L.

[0091] The solvents were ethylene carbonate (EC) and ethyl methyl carbonate (EMC) in a volume ratio of 1:1.

[0092] 2. A method for preparing an electrolyte, comprising the following steps: dissolving an inorganic conductive lithium salt in a solvent, and then adding additives to obtain an electrolyte;

[0093] Specifically:

[0094] (1) Mix ethylene carbonate (EC) and dimethyl carbonate (DMC) in an argon-containing glove box according to a volume ratio of 1:1, and use molecular sieves and lithium hydride to remove water and impurities to obtain a treated mixed solvent .

[0095] (2) In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com