High organic nitrogen concentration wastewater treatment

A treatment method and high organic technology, applied in the field of high organic nitrogen wastewater treatment, can solve the problems of inability to meet the nitrogen discharge requirements and convert it into nitrogen, and achieve the effect of stable and standard discharge and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

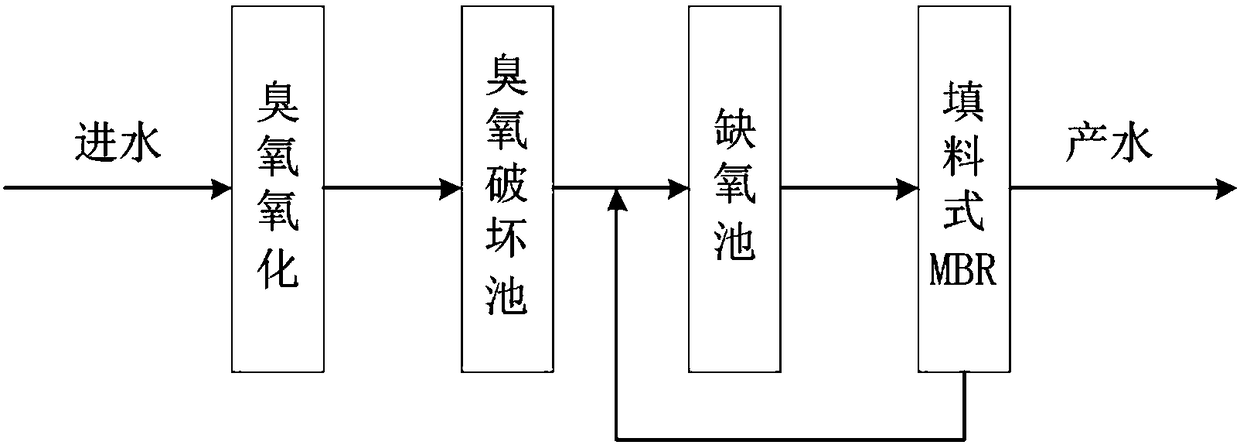

Method used

Image

Examples

Embodiment 1

[0050] A gas field amine solution purifies wastewater, the water quality is: pH 8.9, COD 12000mg / L, total nitrogen 600mg / L, organic nitrogen 560mg / L. The wastewater first enters the catalytic ozonation unit for pretreatment. The dosage of ozone is 40mg / L, and the reaction time is 40min. 280mg / L, of which organic nitrogen is 100mg / L. The effluent enters the ozone destruction pool, and then enters the anoxic pool. The anoxic residence time is 12 hours, and the dissolved oxygen is controlled at 0.1mg / L. Anoxic effluent enters the packed MBR with a residence time of 36 hours and a reflux ratio of 300%. The COD of the effluent is 59mg / L, the total nitrogen of the effluent is 25mg / L, and the ammonia nitrogen is 0.8mg / L, meeting the requirements of the local sewage discharge standards.

Embodiment 2

[0052] A petrochemical organic nitrogen wastewater, water quality: pH 6.3, COD 6000mg / L, total nitrogen 300mg / L, organic nitrogen 260mg / L. The wastewater first enters the catalytic ozonation unit for pretreatment. The dosage of ozone is 20mg / L, and the reaction time is 20min. 160mg / L, of which organic nitrogen is 60mg / L. The effluent enters the ozone destruction pool, and then enters the anoxic pool. The anoxic residence time is 6 hours, and the dissolved oxygen is controlled at 0.2mg / L. Anoxic effluent enters the packed MBR with a residence time of 24 hours and a reflux ratio of 200%. The COD of the effluent is 50mg / L, the total nitrogen of the effluent is 20mg / L, and the ammonia nitrogen is 0.5mg / L, meeting the requirements of the local sewage discharge standards.

Embodiment 3

[0054] A petrochemical organic nitrogen wastewater, water quality: pH 7.5, COD 9000mg / L, total nitrogen 450mg / L, organic nitrogen 460mg / L. The wastewater first enters the ozone oxidation unit for pretreatment, the dosage of ozone is 30mg / L, and the reaction time is 30min. After the treatment, the COD content in the wastewater is reduced from 9000mg / L to 3500mg / L, and the total nitrogen is reduced from 450mg / L to 100mg / L, of which organic nitrogen is 50mg / L. The effluent enters the ozone destruction pool, and then enters the anoxic pool. The anoxic residence time is 10h, and the dissolved oxygen is controlled at 0.1mg / L. Anoxic effluent enters the packed MBR with a residence time of 30 hours and a reflux ratio of 250%. The COD of the effluent is 55mg / L, the total nitrogen of the effluent is 25mg / L, and the ammonia nitrogen is 0.3mg / L, meeting the requirements of the local sewage discharge standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com