Chemical silver plating solution for surface treatment of printed circuit board (PCB)

A printed circuit board, chemical silver plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of assembly limitation, high cost, difficult operation, etc. Weldability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

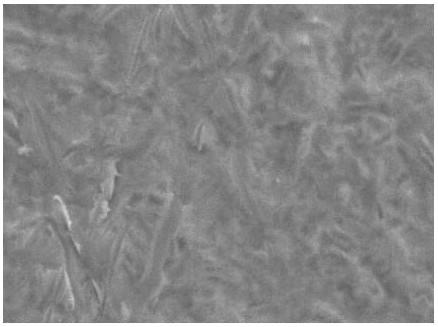

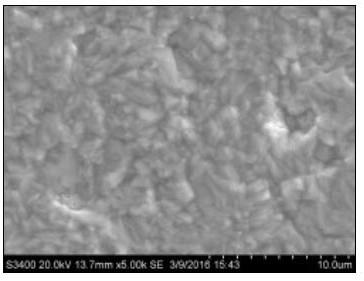

Image

Examples

Embodiment 1

[0050] EDTA 15g

[0052] 18 carbon methyl stearate 1.1g

[0053] Tolyltriazole 1.0g

[0054] Silver nitrate 1.0 g

[0055] 6 grams of nitric acid to adjust the acidity of the solution to 0.12

[0056] Distilled water to make up to 1 liter.

Embodiment 2

[0058] EDTA 20g

[0060] 18 carbon methyl stearate 15g

[0061] Tolyl benzotriazole 2.0 g

[0062] Silver nitrate 2.0 g

[0063] 8 grams of nitric acid to adjust the acidity of the solution to 0.12

[0064] distilled water up to 1 liter

[0065] The electroless silver plating solution for surface treatment of printed circuit boards of the present invention can deposit a metal silver layer on the copper circuit of the circuit board; the thickness of the formed silver plating layer is uniform, between 0.15-0.3 microns; it can effectively guarantee the subsequent assembly of the circuit board Solderability of components; can withstand 5 times of reflow soldering without changing color; can ensure that the bite of copper wire does not exceed 10% of the copper thickness; can ensure that there is no rust or discoloration after 24 hours of neutral salt spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com