Industrial production method of sprouted millet

A kind of technology of corn and germination device, which is applied in the field of germinated grains, can solve the problems of no increase but decrease of nutrient content, inability to realize industrial production, low germination rate, etc., and achieve the effects of short sprout growth length, improved transformation and content, and shortened germination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

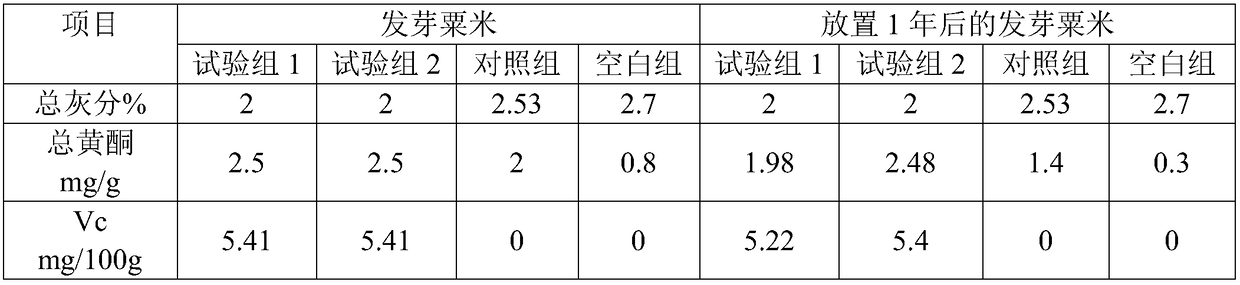

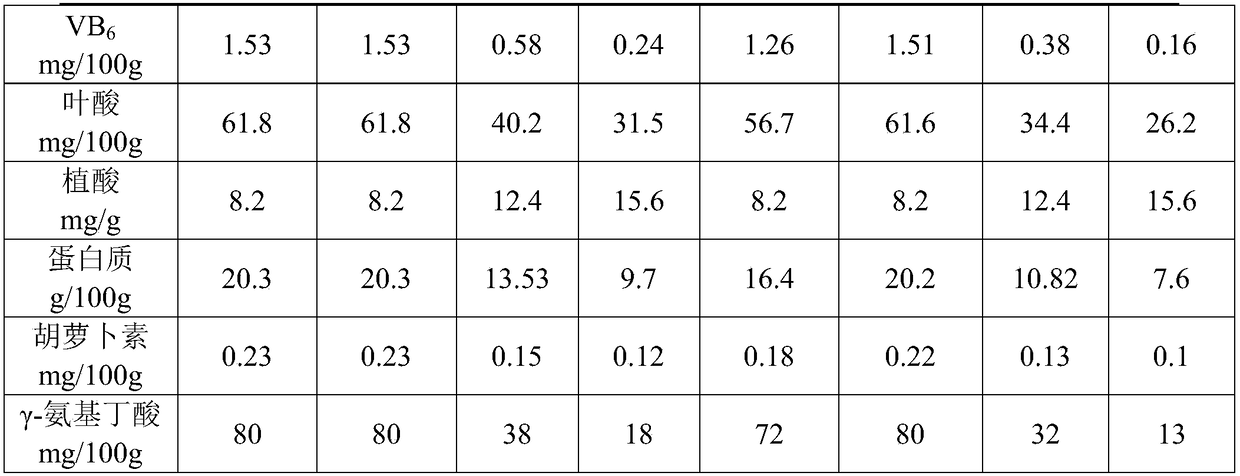

Embodiment 1

[0033] First screen with a screening machine to remove rice husks, stones, and shriveled grains; after husking, perform color selection to remove impurities, remove mildewed grains and heterochromatic grains, and then clean the selected millet. When cleaning, first rinse with water for 1- 2 times, then soak in fermented rice washing water for 3 minutes, then rinse with clean water, then wash with 0.5% salt water for 1-2 times, and finally rinse with clean water. Put the husked millet in a germination device for germination operation, 0°C low temperature stress for 0.5h, 20°C for 4h, 25°C for 4h, 30°C for 4h, 35°C for 5h, 40°C Hypoxic stress germinates for 0.5h (oxygen content 5%), germinates for 4h at 20°C, and in the process of germination, spray accelerator liquid (10mmol / L calcium chloride), regulator and ozone water (ozone Water concentration is 2mg / L) after germination, wash with clear water, and blast dry at 40° C. for 20 hours to obtain germinated corn.

[0034] The re...

Embodiment 2

[0037] First screen with a screening machine to remove rice husks, stones, and shriveled grains; after husking, perform color selection to remove impurities, remove mildewed grains and heterochromatic grains, and then clean the selected millet. When cleaning, first rinse with water for 1- 2 times, then soak in fermented rice washing water for 4 minutes, then rinse with clean water, then wash with 0.5% salt water for 1-2 times, and finally rinse with clean water. Put the shelled millet in a germination device for germination operation, 0°C low temperature stress for 0.5h, 20°C for 5h, 25°C for 5h, 30°C low oxygen stress for 5h, 35°C low oxygen stress for 6h, 40°C Hypoxic stress germinated for 1h (oxygen content 10%), germinated for 5h at 20°C, and in the process of germination, spray accelerator liquid (10mmol / L calcium chloride), regulator and electrolyzed water (electrolyzed water) in the germinator every 35min The pH value of the corn is 12), after the germination is finishe...

Embodiment 3

[0041] First screen with a screening machine to remove rice husks, stones, and shriveled grains; after husking, perform color selection to remove impurities, remove mildewed grains and heterochromatic grains, and then clean the selected millet. When cleaning, first rinse with water for 1- 2 times, then soak in fermented rice washing water for 5 minutes, then rinse with clean water, then wash with 0.5% salt water for 1-2 times, and finally rinse with clean water. Put the shelled millet in a germination device for germination operation, 0°C low temperature stress for 0.5h, 20°C for 6h, 25°C for 6h, 30°C for 6h, 35°C for 6h, 40°C Hypoxic stress germinated for 2h (oxygen content 15%), germinated for 6h at 20°C, and during the germination process, sprayed accelerating liquid (20mmol / L sodium chloride and 10mmol / L calcium chloride) in the germinator every 40min, adjusted agent and bactericide (the volume ratio of electrolyzed water and ozone water is 5:1, the concentration of ozone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com