Non-combustible non-immersible steel ladle upper nozzle and preparation method thereof

A nozzle and ladle technology, applied in the field of no-burning and non-immersing ladle upper nozzle and its preparation, can solve the problems of solid waste pollution of aluminum chromium slag, etc., and achieve the effects of good thermal shock stability, low cost and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

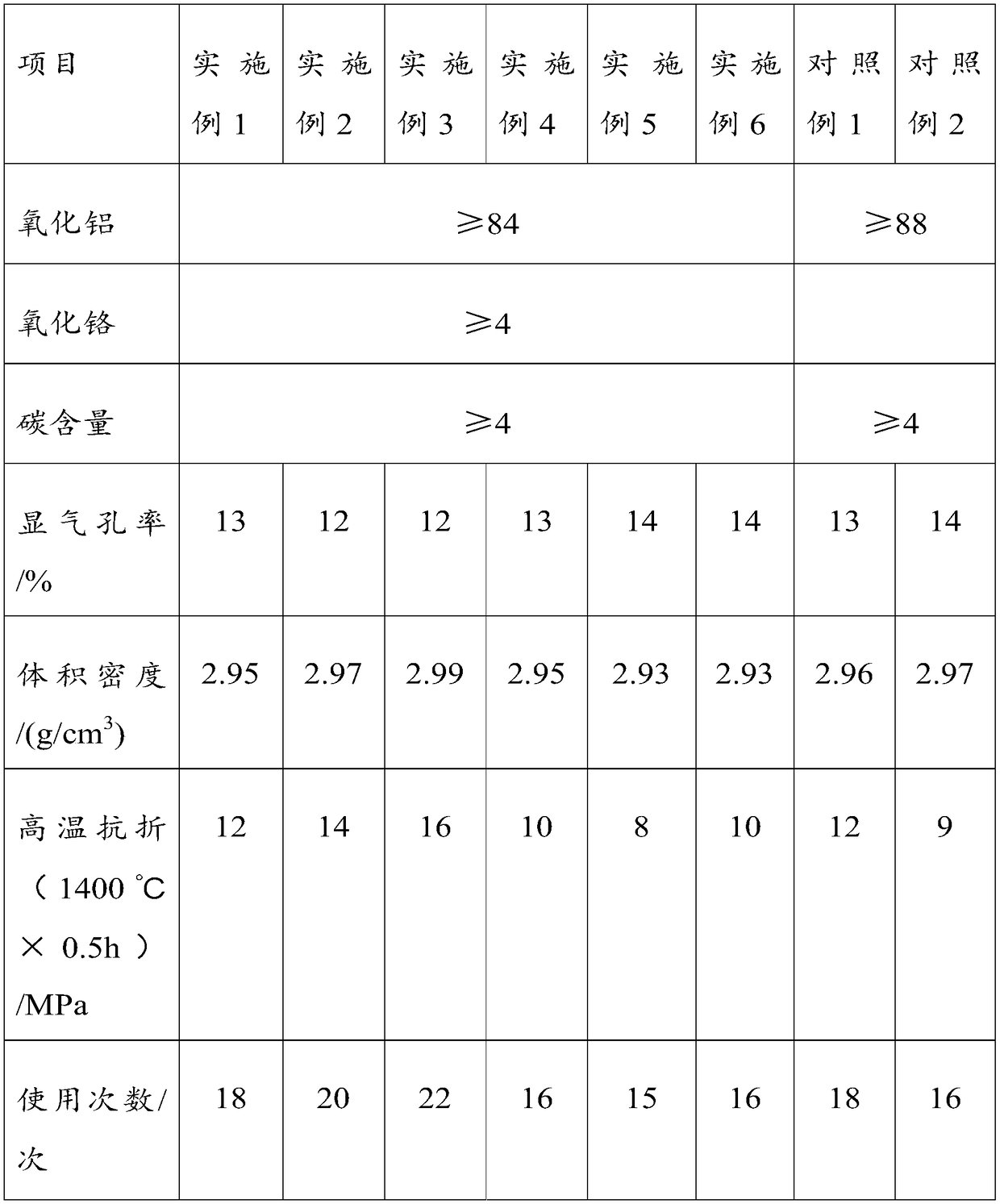

Examples

Embodiment 1

[0027] The preparation method of the non-burning and non-immersing ladle upper nozzle provided by the present embodiment comprises the following steps:

[0028] According to parts by weight, add 8 parts of activated alumina micropowder, 2 parts of graphite and 1 part of high-temperature pitch powder, 22 parts of white corundum, 3 parts of metal aluminum, 2 parts of metal silicon and 1 part of boron carbide into a conical mixer and mix evenly. Mix for 30 minutes to obtain mixed powder.

[0029] Add aluminum chrome slag and plate-shaped corundum as aggregates, add them to the kneader for 4 minutes, add 4 parts of thermosetting phenolic resin and knead for 10 minutes, then add the above-mentioned mixed powder and knead for 20-30 minutes, then discharge the material, and keep the material for 18 hours , Machine pressed into bricks, dried at 300°C for 50 hours to make the ladle upper nozzle.

Embodiment 2

[0031] The preparation method of the non-burning and non-immersing ladle upper nozzle provided by the present embodiment comprises the following steps:

[0032] According to parts by weight, add 7 parts of activated alumina micropowder, 2 parts of graphite and 1 part of high-temperature pitch powder, 22 parts of white corundum, 4 parts of metallic aluminum, 2 parts of metallic silicon and 1 part of boron carbide into a conical mixer and mix evenly. Mix for 30 minutes to obtain mixed powder.

[0033] Add aluminum chrome slag and plate-shaped corundum as aggregates, add them to the kneader for 4 minutes, add 4 parts of thermosetting phenolic resin and knead for 10 minutes, then add the above-mentioned mixed powder and knead for 20-30 minutes, then discharge the material, and keep the material for 18 hours , Machine-pressed into bricks, dried at 300°C for 60 hours to make the ladle upper nozzle.

Embodiment 3

[0035] The preparation method of the non-burning and non-immersing ladle upper nozzle provided by the present embodiment comprises the following steps:

[0036] According to parts by weight, add 6 parts of activated alumina micropowder, 2 parts of graphite and 1 part of high-temperature pitch powder, 22 parts of white corundum, 5 parts of metal aluminum, 2 parts of metal silicon and 1 part of boron carbide into a conical mixer and mix evenly. Mix for 30 minutes to obtain mixed powder;

[0037] Add aluminum chrome slag and plate-shaped corundum as aggregates, add them to the mixing machine for 4 minutes, add 4 parts of thermosetting phenolic resin and mix them for 10 minutes, then add the above-mentioned mixed powder and mix them for 20-30 minutes before discharging, and keep the materials for 20 hours , Machine-pressed into bricks, dried at 200°C for 48 hours to make the ladle upper nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com