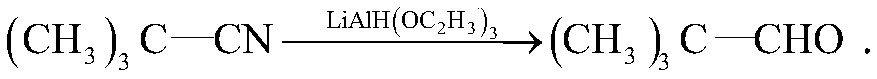

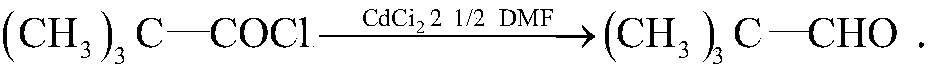

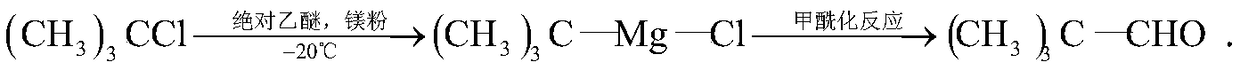

Method for preparing trimethylacetaldehyde

A technology of pivalaldehyde and pivaloyl chloride, which is applied in the field of pivalaldehyde preparation, can solve the problems of cumbersome steps, poor separation of catalysts and salt compounds, troublesome catalyst recovery and treatment, etc., and achieve the effect of simple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of pivalaldehyde, this preparation method comprises the steps:

[0027] (1) Carry out reduction reaction at first: take pivaloyl chloride as raw material, take palladium-charcoal as catalyst, acetonitrile as reaction solvent, N,N-diisopropylethylamine as acid-binding agent, carry out reduction reaction with hydrogen;

[0028] (2) Filtrate after reduction reaction secondly: filter reaction solution, obtain filtrate and palladium charcoal catalyst, the organic salt of generation is dissolved in solvent, and palladium charcoal catalyst recovery can reuse;

[0029] (3) Carry out rectification at last: carry out rectification treatment to filtrate, collect the cut of 76-78 ℃, promptly obtain pivalaldehyde product, and its yield can reach 73%, content>98%.

Embodiment 2

[0031] According to the preparation method of pivalaldehyde described in embodiment 1, in the described step (1), the reduction reaction temperature is room temperature, the reaction time 4-6h, the reaction pressure is 0.4-0.6MPa, the volume ratio of pivaloyl chloride and solvent The molar ratio of pivaloyl chloride to acid-binding agent is 1:1-1:3, and the mass ratio of palladium-carbon to pivaloyl chloride is 4%-10%.

Embodiment 3

[0033] According to the preparation method of pivalaldehyde described in embodiment 1 or 2, the reduction reaction formula in the described step (1) is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com