Carbon fiber/ABS composite material for 3D printing and preparation method thereof

A composite material and 3D printing technology, applied in the direction of additive processing, etc., can solve problems such as large shrinkage rate and warpage of parts, achieve the effect of improving bonding ability, ensuring processing performance and mechanical properties, and preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

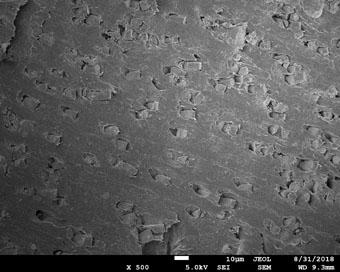

Image

Examples

experiment example 1

[0022] Carbon fiber / ABS composite material for 3D printing, each component and its mass parts are: 0.3 part of magnesium stearate, 0.5 part of ethylene butyl acrylate, 0.15 part of distearyl pentaerythritol diphosphite, 0.15 part of distearyl pentaerythritol diphosphite, dipropionate disulfide 0.05 parts of stearyl ester, 21 parts of butadiene-styrene-acrylonitrile graft copolymer, and 77 parts of styrene-acrylonitrile copolymer. The mass ratio of butadiene, styrene and acrylonitrile is: 64:26:10; the melt index of styrene-acrylonitrile copolymer is 31.23g / 10min at 220°C and 10kg, and the N content is 7.2%. The bonded acrylonitrile content is 25%, and the number average molecular weight is 68000.

[0023] 210g high-impact butadiene-styrene-acrylonitrile terpolymer, 770g high-flow styrene-acrylonitrile binary copolymer, 3g magnesium stearate, 5g ethylene butyl acrylate, 1.5g distearyl After pentaerythritol diphosphite and 0.5g dioctadecyl dipropionate were fully mixed in a hig...

Embodiment 2

[0026] Carbon fiber / ABS composite material for 3D printing, each component and its mass parts are: 0.3 parts of magnesium stearate, 0.45 parts of ethylene butyl acrylate, 0.2 parts of distearyl pentaerythritol diphosphite, 0.2 parts of dipropionate disulfide 0.05 parts of stearyl ester, 32 parts of butadiene-styrene-acrylonitrile graft copolymer, and 62 parts of styrene-acrylonitrile copolymer. Among them, the mass ratio of butadiene, styrene and acrylonitrile is: 55:28:17; the melt index of styrene-acrylonitrile copolymer is 33.23g / 10min under the condition of 220°C and 10kg, and the N content is 6.8%. The bonded acrylonitrile content was 27%, and the number average molecular weight was 70,000.

[0027]320g high-impact butadiene-styrene-acrylonitrile terpolymer, 620g high-flow styrene-acrylonitrile binary copolymer, 3g magnesium stearate, 4.5g ethylene butyl acrylate, 2g distearyl After pentaerythritol diphosphite and 0.5g dioctadecyl dipropionate were fully mixed in a high-...

Embodiment 3

[0030] 3D printing carbon fiber / ABS material, its components and their mass parts are: 0.3 parts of magnesium stearate, 0.5 parts of ethylene butyl acrylate, 0.15 parts of distearyl pentaerythritol diphosphite, 0.15 parts of distearyl pentaerythritol diphosphite, dipropionate disulfide 0.05 parts of stearyl ester, 26 parts of butadiene-styrene-acrylonitrile graft copolymer, 69 parts of styrene-acrylonitrile copolymer, and 4 parts of surface-modified carbon fiber. Among them, the mass ratio of butadiene, styrene and acrylonitrile is 57:28:15; the melt index of styrene-acrylonitrile copolymer is 32.05g / 10min under the condition of 220°C and 10kg, and the N content is 7.0%. The content of acrylonitrile is 23%, and the number average molecular weight is 70000.

[0031] 260g high-impact butadiene-styrene-acrylonitrile terpolymer, 690g high-flow styrene-acrylonitrile binary copolymer, 3g magnesium stearate, 5g ethylene butyl acrylate, 1.5g distearyl After pentaerythritol diphosphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com