Method for mixed fermentation of probiotics containing bacillus coagulans

A technology of Bacillus coagulans and micro-ecological preparations, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., and can solve the problems of single strain and large limitations in fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

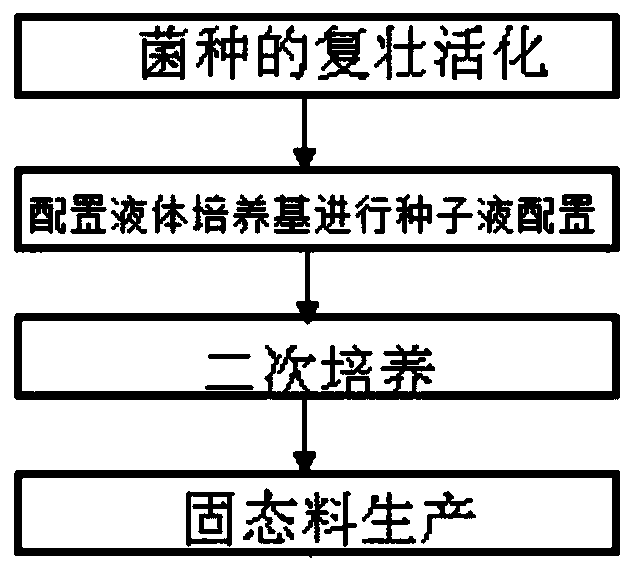

[0027] Such as figure 1 Shown, a kind of mixed fermentation probiotics method containing bacillus coagulans comprises the following steps:

[0028] The first step is the rejuvenation and activation of the strains. Inoculate the required strains of Lactobacillus bulgaricus, Saccharomyces cerevisiae, and Bacillus coagulans on the corresponding solid medium, put them in a constant temperature incubator for 24 hours, and then take them out and put them away. Store in a 5°C refrigerator for later use;

[0029] The second step is to configure the liquid culture medium to configure the seed liquid. First, the culture medium of Lactobacillus bulgaricus, the culture medium group of Saccharomyces cerevisiae, and the culture medium of Bacillus coagulans are respectively configured, and then the culture medium of the configured Lactobacillus bulgaricus, The medium group of Saccharomyces cerevisiae and the medium group of Bacillus coagulans were put into the sterilizing pot for sterilizat...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of mixed fermentation probiotics method containing bacillus coagulans comprises the following steps:

[0046] The first step is the rejuvenation and activation of the strains. Inoculate the required strains of Lactobacillus bulgaricus, Saccharomyces cerevisiae, and Bacillus coagulans on the corresponding solid medium, put them in a constant temperature incubator for 24 hours, and then take them out and put them away. Store in a 3°C refrigerator for later use;

[0047] The second step is to configure the liquid culture medium to configure the seed liquid. First, the culture medium of Lactobacillus bulgaricus, the culture medium group of Saccharomyces cerevisiae, and the culture medium of Bacillus coagulans are respectively configured, and then the culture medium of the configured Lactobacillus bulgaricus, The medium group of Saccharomyces cerevisiae and the medium group of Bacillus coagulans were put into the sterilizing pot for sterilizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com