A Method of Prolonging the Service Life of Blast Furnace Main Ditch

A blast furnace, life-span technology, applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of insufficient water cooling, increase of solid waste, waste of refractory materials and gas, etc., to reduce surface temperature, facilitate maintenance and repair, avoid The effect of mechanical scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

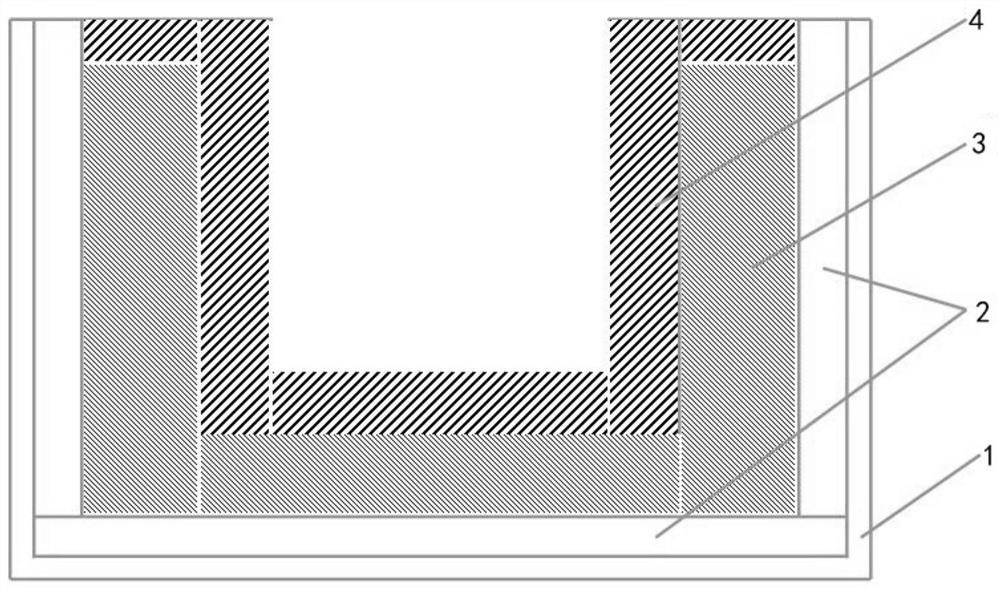

[0028] This embodiment provides a method for prolonging the service life of the blast furnace main ditch, the steps comprising:

[0029] Lay a cooling wall with a thickness of 120mm on the inner wall and bottom of the steel channel of the blast furnace main ditch, and then successively build a layer of ultra-microporous carbon bricks with a thickness of 500mm, and microporous corundum bricks with a thickness of 380mm as the lining Floor. A galvanic couple is embedded between the microporous carbon brick layer and the microporous corundum brick layer to measure the temperature of the hot surface of the carbon brick. Change the main ditch girder of the blast furnace into a prefabricated part. When building the inner lining, place the main ditch girder horizontally, and embed both ends in the inner lining to form a slag stopper.

[0030] In terms of mass percentage, Al in the microporous corundum brick 2 o 3 Content is 85%, SiO 2 The content is 6%, the slag erosion resistance...

Embodiment 2

[0035] This embodiment provides a method for prolonging the service life of the blast furnace main ditch, the steps comprising:

[0036] Change the main ditch girder of the blast furnace into a prefabricated part, first lay a stave with a thickness of 125mm on the steel channel inner wall and bottom of the girder of the main ditch of the blast furnace, and then successively build a layer of microporous carbon bricks with a thickness of 475mm, and as an inner The thickness of the lining is a layer of microporous corundum bricks with a thickness of 400mm. The gap between the prefabricated part and the main groove is blocked by self-flowing corundum material.

[0037] In terms of mass percentage, Al in the microporous corundum brick 2 o 3 content of 83%, SiO 2 The content is 7%, the slag erosion resistance of microporous corundum bricks is ≤10%, the molten iron corrosion resistance index is ≤1.5%, the pore diameter is ≤1.0μm, the pore volume ratio is ≥70%, and the bulk density...

Embodiment 3

[0042] This embodiment provides a method for prolonging the service life of the blast furnace main ditch, the steps comprising:

[0043] Change the main ditch girder of the blast furnace into a prefabricated part, first lay a stave with a thickness of 140mm on the steel channel inner wall and the bottom of the girder of the main ditch of the blast furnace, and then successively build a layer of microporous carbon bricks with a thickness of 500mm, and as an inner The thickness of the lining is a microporous corundum brick layer of 350mm. The gap between the prefabricated part and the main groove is blocked by self-flowing corundum material.

[0044] In terms of mass percentage, Al in the microporous corundum brick 2 o 3 content of 83%, SiO 2 The content is 5%, the slag erosion resistance of microporous corundum bricks is ≤10%, the molten iron corrosion resistance index is ≤1.5%, the pore diameter is ≤1.0μm, the pore volume ratio is ≥70%, and the bulk density is 3.2g / cm 3 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com