Antibacterial mother solution for producing antibacterial ultra-high molecular weight polyethylene fibers

A polyethylene fiber, ultra-high molecular weight technology, applied in the direction of single-component polyolefin rayon, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of fiber performance decline and UHMWPE fiber performance decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

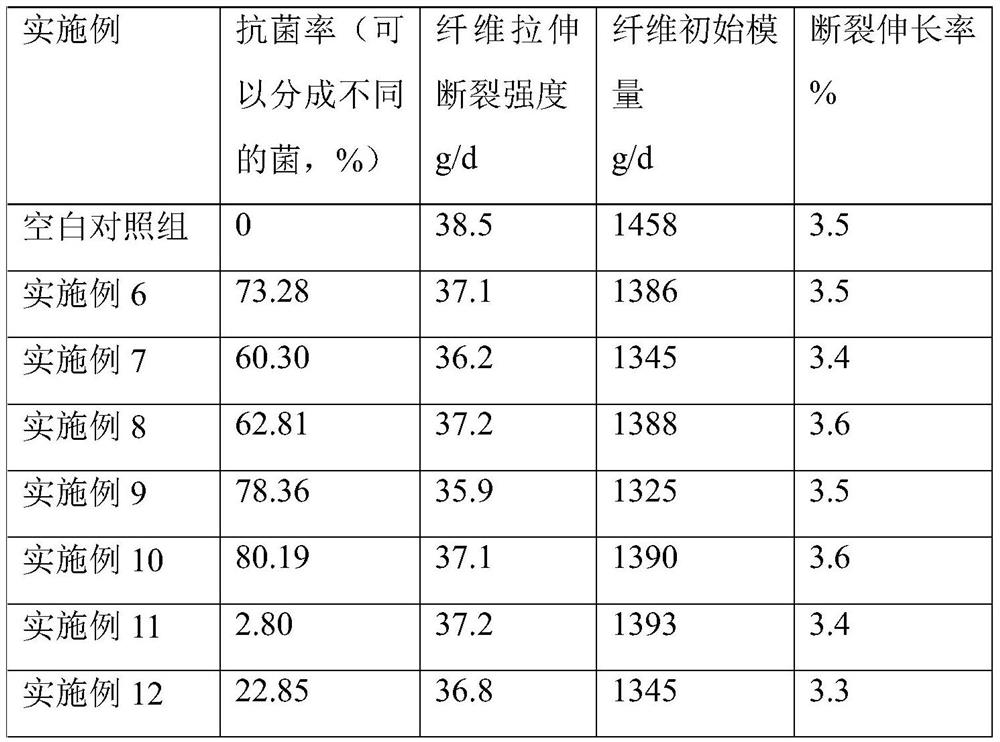

Examples

Embodiment 1

[0019] The preparation of embodiment 1 antibacterial mother solution 1

[0020] In batching kettle, add white oil 8000g, polyvinyl quaternary ammonium salt antibacterial polymer 2000g, polyvinyl alcohol 60g, sodium lauryl sulfate 130g, polyethylene graft maleic anhydride PE-g-MAH 300g, stirring is heated up to 110°C, wait until all the materials are dissolved and mixed evenly, then cool down to obtain about 10.5kg of antibacterial mother solution 1.

Embodiment 2

[0021] The preparation of embodiment 2 antibacterial mother liquor 2

[0022] Add white oil 8000g, polyvinyl quaternary phosphonium salt antibacterial polymer 2000g, EFKA4560 65g, sodium n-dodecylbenzenesulfonate 140g, polyethylene graft maleic anhydride / styrene copolymer 300g in the batching kettle, stir and heat up To 110, ℃ until all materials are dissolved and mixed evenly, cooled to obtain about 10.5kg of antibacterial mother solution 2.

Embodiment 3

[0023] The preparation of embodiment 3 antibacterial mother liquor 3

[0024] Add white oil 8000g, polyvinylguanidine salt antibacterial polymer 2000g, SolsperseS2700065g, nonylphenol polyoxyethylene (10) ether-2-sulfosuccinic acid monoester disodium salt 170g, halogenated polyethylene 280g in batching kettle , stir and heat up to 110°C until all materials are dissolved and mixed evenly, then cooled to obtain about 10.5kg of antibacterial mother solution 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com