Polyamide reverse osmosis membrane as well as preparation method and application thereof

A reverse osmosis membrane and polyamide technology, which is applied in the field of polyamide reverse osmosis membrane preparation, can solve the problems of low life, small water flux, and low reverse osmosis efficiency, so as to prolong life, prolong service life, and improve durability. The effect of UV properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This embodiment provides a zinc-doped carbon quantum dot:

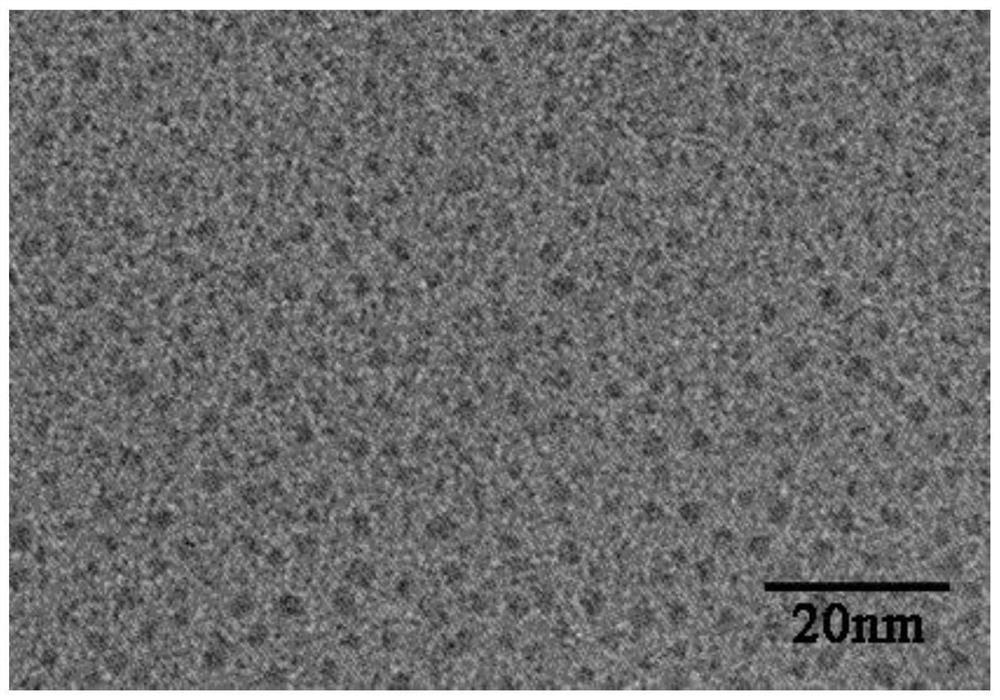

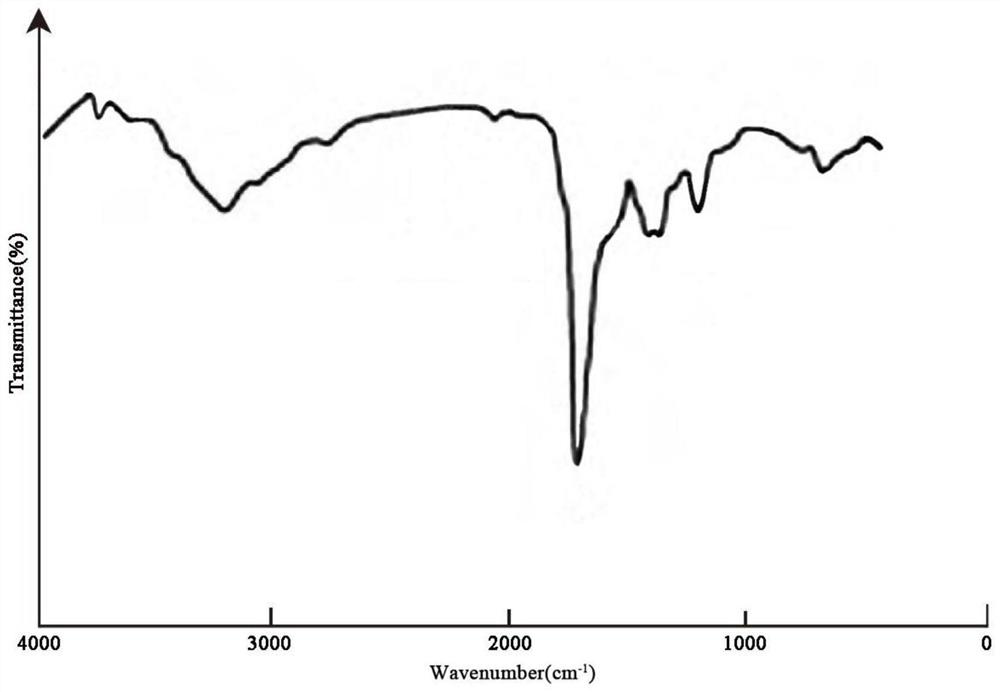

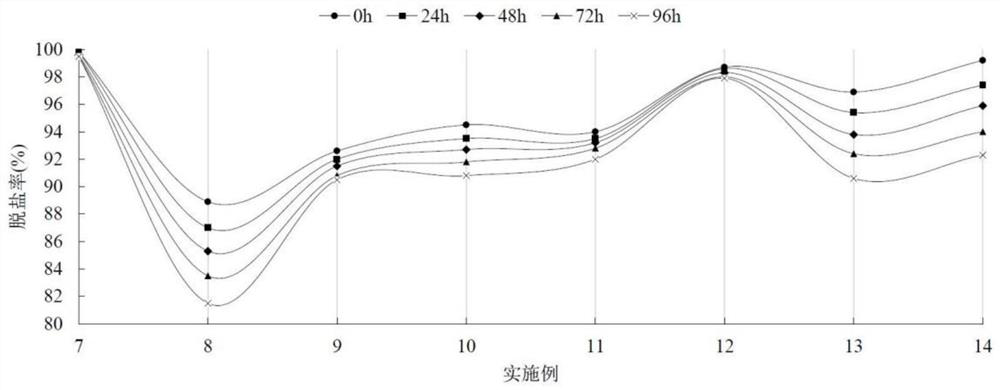

[0087] Disperse 2g of citric acid and 1.2g of zinc acetate into 300mL of ultrapure water evenly, then add 2.5g of thiourea, mix well and heat at 185°C for 6 hours. After the reaction is completed, cool to room temperature to obtain a brown liquid, which is removed with a 0.22μm filter membrane. Large particles of impurities are then subjected to high-speed centrifugation at 12000r / min for 30 minutes to filter out small precipitates to obtain zinc-doped carbon quantum dots. Its electron microscope picture is as figure 1 As shown, it can be seen that it presents a regular spherical structure, good dispersion, high uniformity, and a particle size between 2 and 5nm; its infrared spectrum is shown in figure 2 Shown, display 3500~2600cm -1 The left and right regions contain the vibration characteristic peaks of O-H and N-H, and the 1700-1500cm -1 The left and right regions contain vibration characteristic peaks o...

Embodiment 2

[0089] This embodiment provides a carbon quantum dot, the preparation method of which is basically the same as that of Embodiment 1, except that zinc acetate is not added to the raw material.

Embodiment 3

[0091] This embodiment provides a carbon quantum dot, the preparation method of which is basically the same as that of Embodiment 1, except that the thiourea in the raw material is replaced by ethylenediamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com