Track shielding door vertical column end plate assembly

A screen door and column technology, applied in the direction of window/door frame, coating, leaf frame, etc., can solve the problem of insulation performance degradation, etc., and achieve the effect of fast liquid flow, uniform mixing, easy dispersion and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

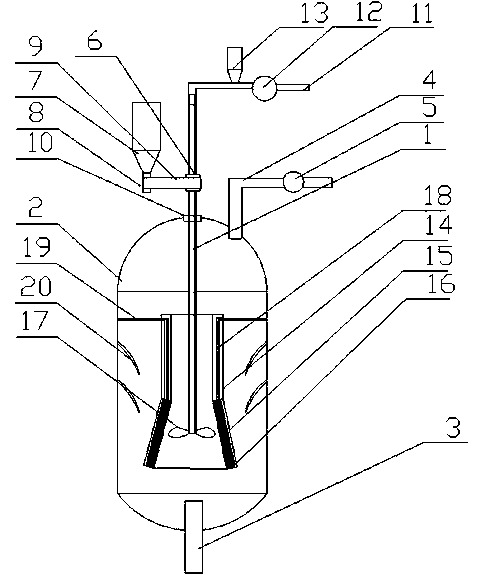

[0031] Such as figure 1 As shown, a kind of track screen door column end plate assembly provided by the present invention, the column bottom plate at the bottom of the column and the top plate at the top of the column, both the column bottom plate and the top plate adopt FR-4 grade purity higher than 99.5%. Made of epoxy resin; the insulating polypropylene material is coated with composite insulating varnish; the formula of the composite insulating varnish includes: polyurethane resin, acrylic resin, rosin water, curing agent, plasticizer and inorganic filler, according to Parts by weight, wherein 100 parts of polyurethane resin, 12 parts of acrylic resin, 80 parts of rosin water, 4 parts of curing agent, 0.6 part of plasticizer, and 24 parts of inorganic filler. The inorganic fillers include nano-zinc oxide, calcium silicate, diatomite and nano-carbon powder, which include 25% nano-zinc oxide, 35% calcium silicate, 30% diatomaceous earth, and the rest are nanometer toner.

...

Embodiment 2

[0039] The present invention provides a rail screen door column end plate assembly, the column bottom plate at the bottom of the column and the top plate at the top of the column, both the column bottom plate and the top plate use FR-4 grade epoxy resin with a purity higher than 99.5%. Made; the insulating polypropylene material is coated with a composite insulating varnish; the formula of the composite insulating varnish includes: polyurethane resin, acrylic resin, rosin water, curing agent, plasticizer and inorganic filler, in parts by weight, Among them, 100 parts of polyurethane resin, 12 parts of acrylic resin, 80 parts of rosin water, 4 parts of curing agent, 0.6 parts of plasticizer, and 24 parts of inorganic filler. The inorganic fillers include nano-zinc oxide, calcium silicate, diatomite and nano-carbon powder, which include 25% nano-zinc oxide, 35% calcium silicate, 30% diatomaceous earth, and the rest are nanometer toner.

[0040] The invention also discloses a me...

Embodiment 3

[0047] The present invention provides a rail screen door column end plate assembly, the column bottom plate at the bottom of the column and the top plate at the top of the column, both the column bottom plate and the top plate use FR-4 grade epoxy resin with a purity higher than 99.5%. Made; the insulating polypropylene material is coated with a composite insulating varnish; the formula of the composite insulating varnish includes: polyurethane resin, acrylic resin, rosin water, curing agent, plasticizer and inorganic filler, in parts by weight, Among them, 90 parts of polyurethane resin, 11 parts of acrylic resin, 70 parts of rosin water, 3 parts of curing agent, 0.55 parts of plasticizer, and 22 parts of inorganic filler. Among them, the inorganic fillers include nano-zinc oxide, calcium silicate, diatomite and nano-carbon powder, which include 22.5% nano-zinc oxide, 32.5% calcium silicate, 25% diatomaceous earth, and the rest are nanometer toner.

[0048] The invention als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com