Vitamin A microcapsule and preparation method and applications thereof

A vitamin and microcapsule technology, applied in the field of vitamins, can solve the problems of poor stability of vitamin A microcapsules and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

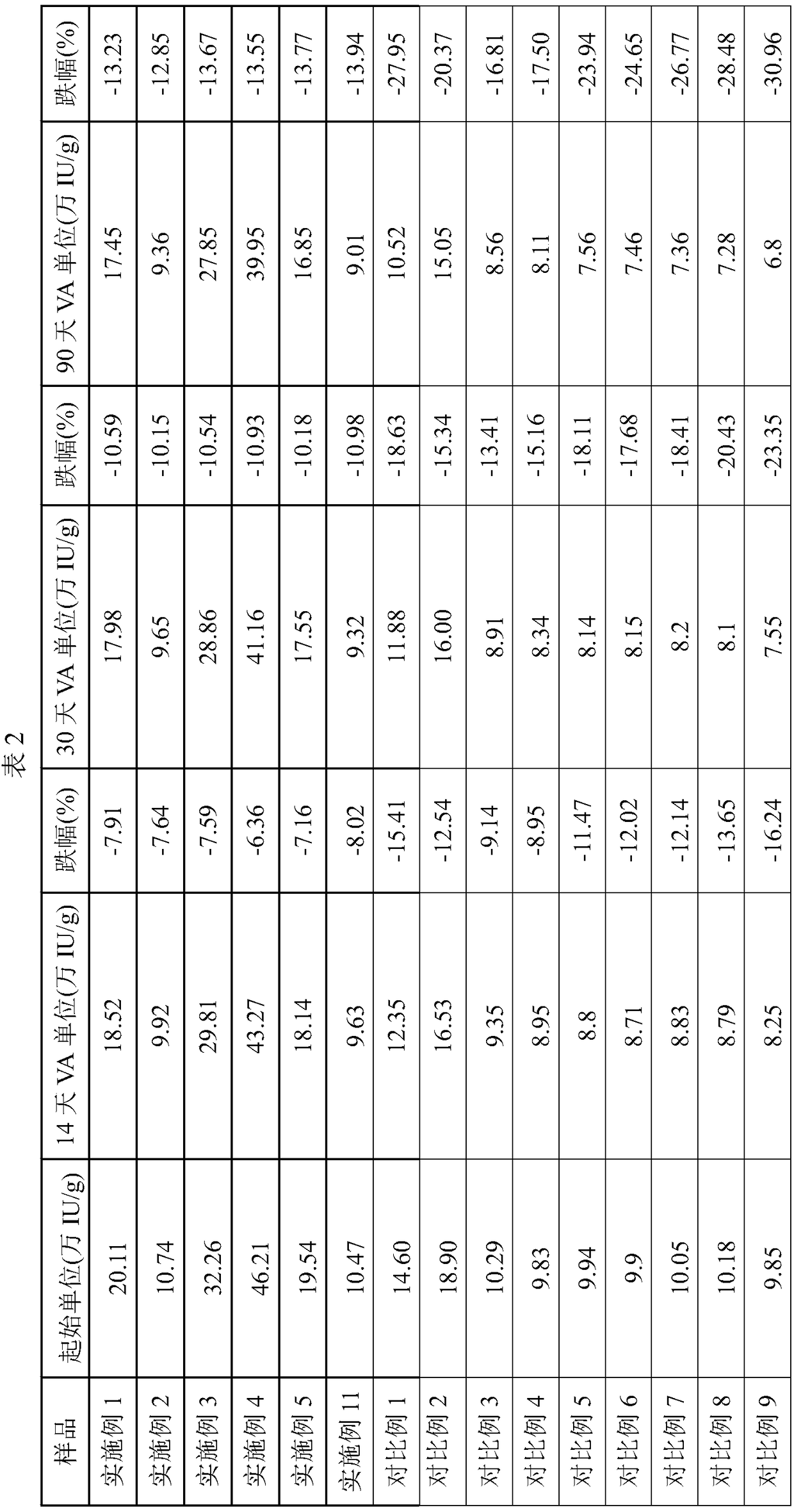

Examples

Embodiment 1

[0033]Add 1kg of ascorbyl palmitate, 1.2kg of carnosic acid, 3kg of acetylcholine and 4kg of palm oil into the oil-dissolving pot, vacuumize and replenish nitrogen three times, stir at 50°C for 30min, and then add 20kg of vitamin A acetate crystals (2.812 million IU / g) continue stirring until vitamin A acetate crystals dissolve, forming a uniform core material containing vitamin A.

[0034] Add 30kg of gelatin (isoelectric point 4.8), 1kg of sodium carbonate and 45kg of maltodextrin into the emulsification pot with 100kg of purified water, stir and dissolve at 50°C to form a uniform wall material aqueous solution.

[0035] Slowly add the core material into the high-speed shear (line speed 6.0m / s, the same below) wall material aqueous solution. After adding the core material, continue shearing and stirring at 50°C for 20 minutes, and then homogenize under high pressure once. The mass pressure is 25MPa, and the pH value is between 6.0 and 7.5 and the oil droplet size D 50 Vitam...

Embodiment 2

[0039] Add 0.2kg of ascorbyl palmitate, 0.4kg of carnosic acid, 1.6kg of phosphatidylcholine and 2kg of peanut oil into the oil-dissolving pot, evacuate and replenish nitrogen three times, stir at 45°C for 30 minutes, and then add 10kg of vitamin A acetate The crystals (2,812,000 IU / g) were continuously stirred until the vitamin A acetate crystals were dissolved to form a uniform vitamin A-containing core material.

[0040] Add 15kg of gelatin (isoelectric point 4.8), 0.4kg of sodium carbonate and 72kg of glucose into an emulsification pot with 100kg of purified water, stir and dissolve at 50°C to form a uniform wall material aqueous solution.

[0041] Slowly add the core material to the high-speed shearing wall material aqueous solution. After adding the core material, continue to shear and stir at 50°C for 20 minutes, and then homogenize under high pressure at 25 MPa to obtain a pH value between 6.0 and Between 7.5 and oil droplet size D 50 Vitamin A emulsion between 0.8 ~ ...

Embodiment 3

[0045] 2kg of ascorbyl palmitate, 4kg of carnosic acid, 8kg of glycerophosphocholine and 12kg of soybean oil were added to the oil-dissolving pot, vacuumed three times to replenish nitrogen, stirred at 60°C for 30min, and then added 32kg of vitamin A acetate crystals ( 2,705,000 IU / g) continue to stir until vitamin A acetate crystals dissolve, forming a uniform core material containing vitamin A.

[0046] Add 40kg of gelatin (isoelectric point 4.8), 1.3kg of choline and 5kg of glucose into an emulsification pot with 120kg of purified water, stir and dissolve at 50°C to form a uniform wall material aqueous solution.

[0047] Slowly add the core material to the high-speed shearing wall material aqueous solution. After adding the core material, continue to shear and stir at 50°C for 20 minutes, and then homogenize under high pressure at 25 MPa to obtain a pH value between 6.0 and Between 7.5 and oil droplet size D 50 Vitamin A emulsion between 0.8 ~ 1.2um.

[0048] The vitamin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com