Heat treatment method for reducing steel casting processing surface weld seam hardness

A heat treatment method and weld hardness technology, which is applied in the field of reducing the weld hardness of the B50A178H processed surface by a new post-weld heat treatment method, can solve problems such as hardness reduction, repair welding hardness reduction, and dimensional deformation, so as to improve production efficiency and prevent dimensional deviation , the effect of reducing the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with specific embodiments.

[0012] A heat treatment method for reducing the hardness of a weld seam on a machined surface of a steel casting, comprising the steps of:

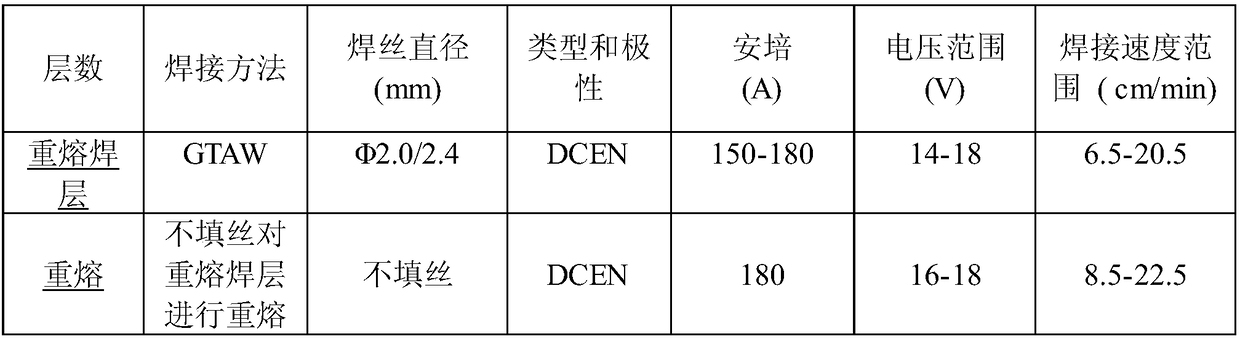

[0013] Step 1: Use argon arc welding filler wire ER90S-B3 to fill and repair the pits of the workpiece after the defects are eliminated. The repair welding requirements should be controlled at 270-350°C according to the process parameters, and the welding current should be controlled at 150-180A , GTAW protective gas is 99.999% Ar gas, the flow rate is 10-18L / min, the number of TIG argon arc welding welding layers is 2-4 layers, straight-forward welding is adopted, and repair welding is performed in layers and lanes. After being flush with the casting, grind or use a milling machine to remove the weld reinforcement, and use a hardness tester to measure the hardness of the weld position of the product;

[0014] Step 2: After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com