A normal temperature curing ultra-high performance concrete column and its construction method

An ultra-high-performance, concrete column technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems that cannot be implemented on site and are difficult to apply to actual projects, and achieve convenient construction, good feasibility, The effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of normal temperature maintenance ultra-high performance concrete column of this embodiment, its concrete column 1 is made of water, cement, silica fume, quartz powder, polycarboxylate high-efficiency water reducing agent, quartz sand and sodium polyacrylate according to the mass ratio of 0.2: It is prepared by mixing and stirring in the ratio of 1:0.15:0.2:0.009:1.75:0.03. The sodium polyacrylate added in the component can absorb 15 to 30 times the water of its own weight during the concrete mixing process, and provide sufficient hydration water for the concrete in the early stage of curing. The polycarboxylate-based high-performance water reducer of this embodiment is purchased on the market, which can prevent the loss of concrete slump without causing obvious retardation, exert a high plasticizing effect, have a significant effect on concrete reinforcement, and can reduce concrete shrinkage. Endows concrete with excellent construction workability. The concret...

Embodiment 2

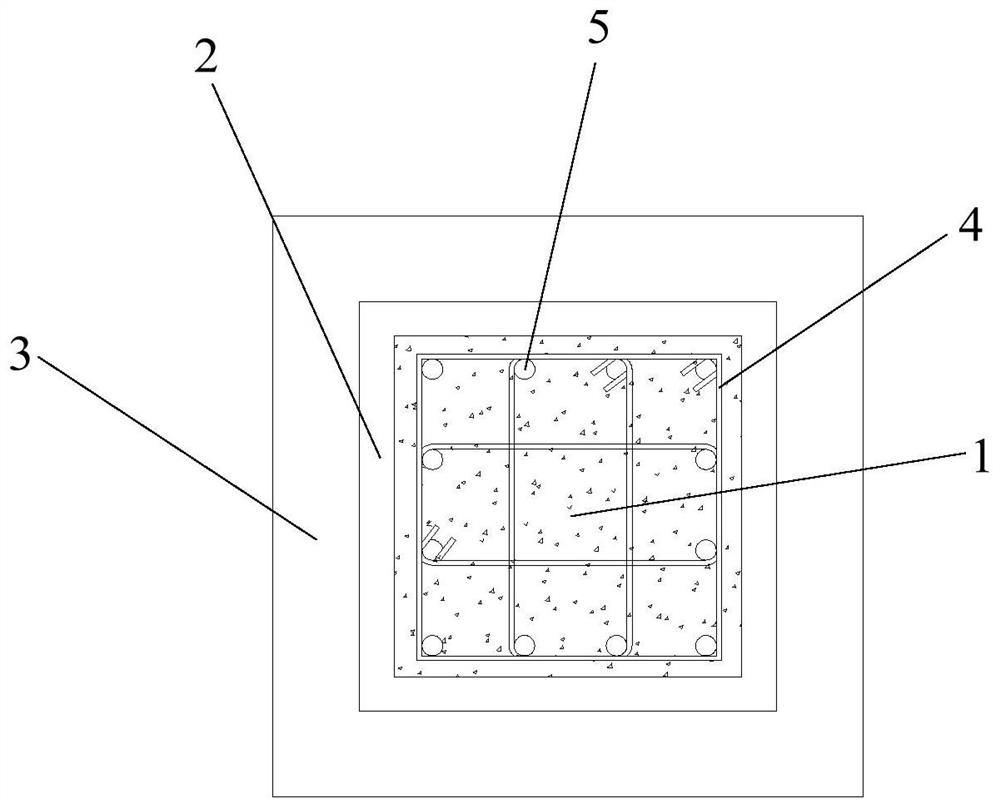

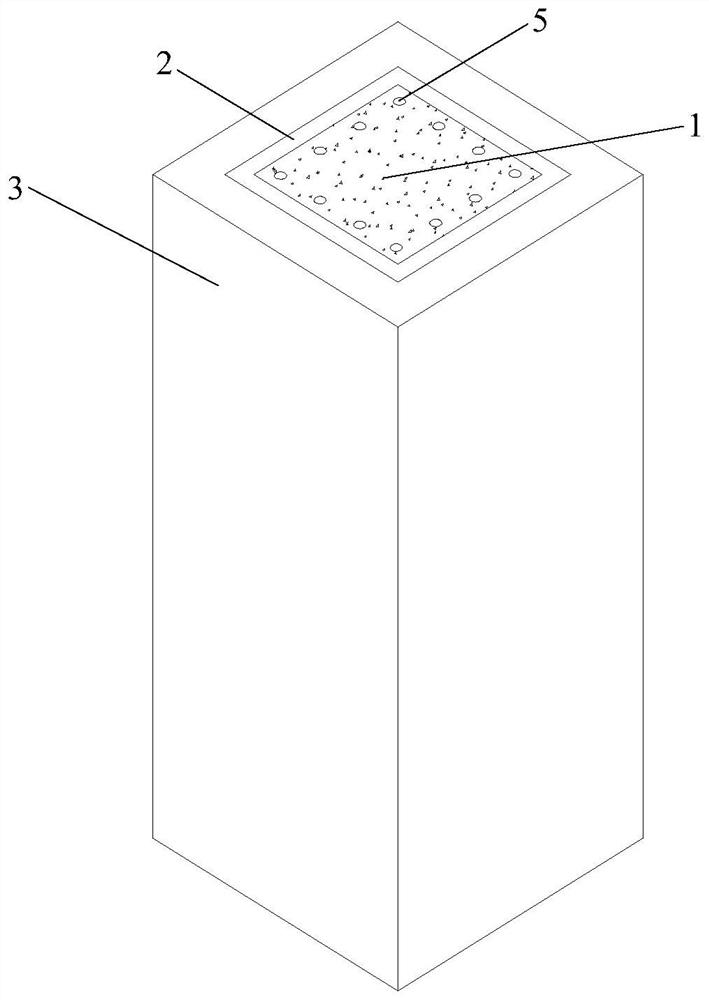

[0028] Please check Figure 1~2 , the construction method of a normal temperature maintenance ultra-high performance concrete column of the present embodiment is used for the concrete column maintenance construction of the embodiment 1, comprising the following steps:

[0029] 1) Four wooden formworks are spliced in pairs to form a hollow cuboid wooden mold 2 . After placing the wooden mold vertically, put the bundled longitudinal reinforcement 5 and high-strength stirrup 4 into the wooden mold 2, the longitudinal reinforcement 5 is inserted into the wooden mold 2 along the length direction of the wooden mold 2, and the high-strength stirrup 4 is parallel to It is arranged at intervals in the direction of the cross section of the wooden mold 2; the high-strength stirrups 4 are bundled into a square shape, and the longitudinal steel bars 5 are located inside the four corners surrounded by the high-strength stirrups 4 .

[0030] 2) Mix water, cement, silica fume, quartz powde...

Embodiment 3

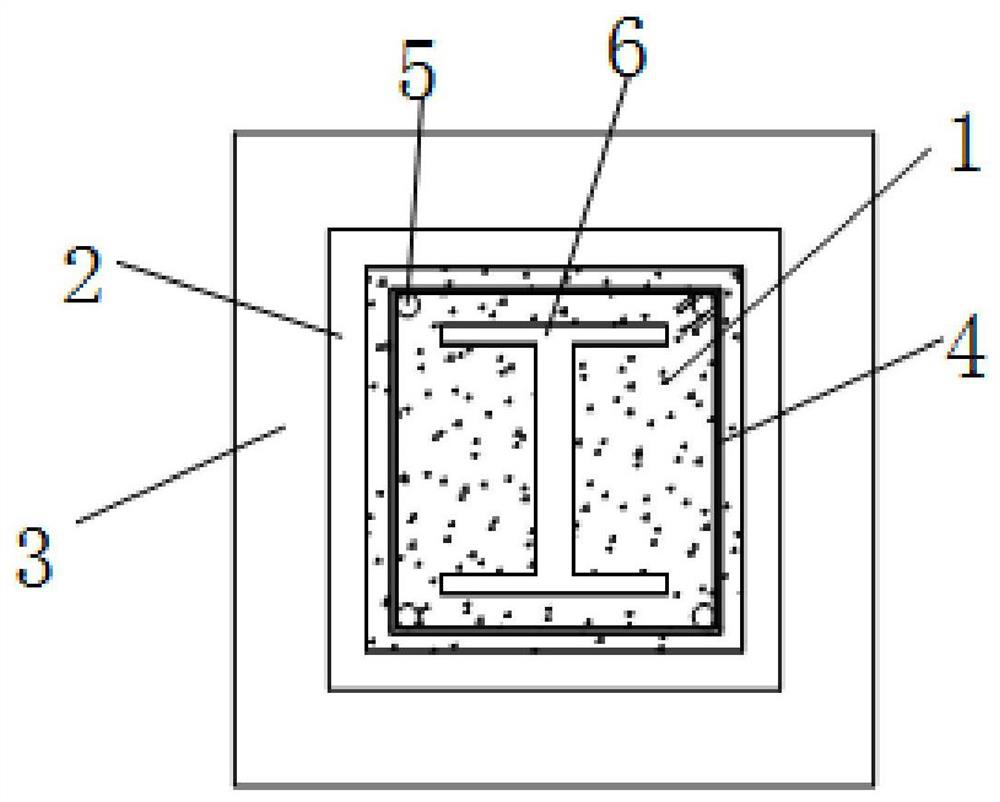

[0036] The difference between this embodiment and embodiment 2 is that: said step 1) also includes inserting the shaped steel into the wooden mold 2 along the length direction of the wooden mold 2, the present embodiment adopts H-shaped steel, and the H-shaped steel 6 is located between the high-strength stirrup 4 and The center position surrounded by longitudinal reinforcement 5. The length of the H-shaped steel 6 and the longitudinal reinforcement 5 is the same as that of the wooden mold 2 . Please refer to the attached Figure 3-4 , the outer periphery of the H-shaped steel 6 of this embodiment is covered with concrete, and the longitudinal reinforcement 5 is inserted between the concrete, and the outer periphery of the longitudinal reinforcement 5 is provided with a high-strength stirrup 4, which effectively ensures the bearing capacity of the concrete column 1 and ensures the construction quality on site.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com