A construction device and method for maintaining ultra-high performance concrete filled steel pipe columns at room temperature

A concrete-filled steel tubular column and ultra-high performance technology, applied in columns, piers, pillars, etc., can solve problems such as difficult application and inability to implement on-site, and achieve the effects of good feasibility, convenient construction, and improved construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

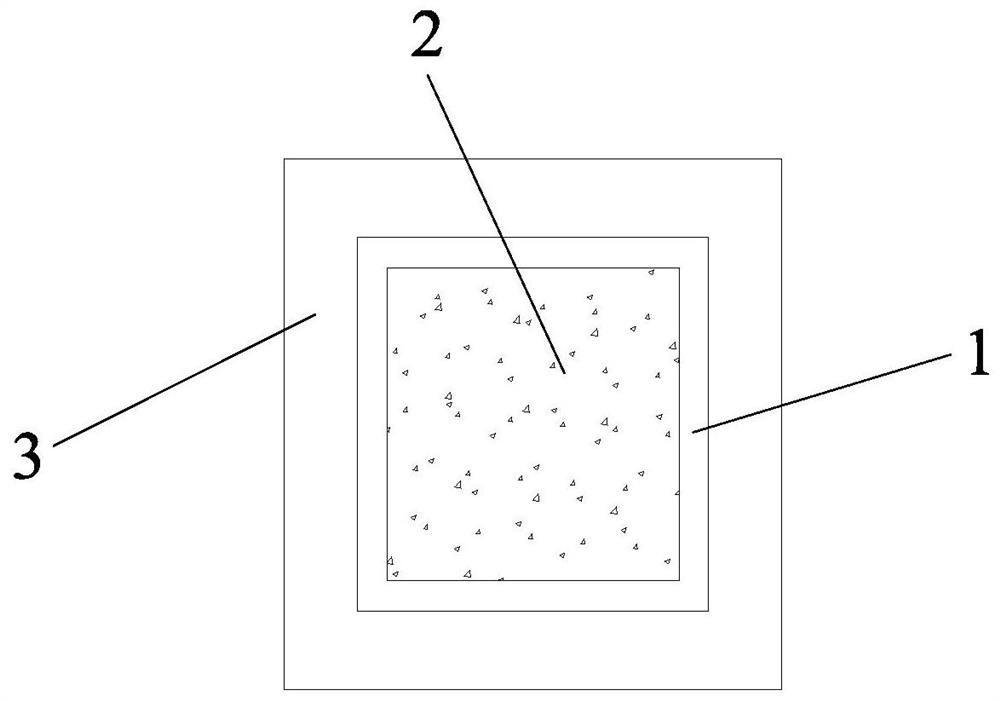

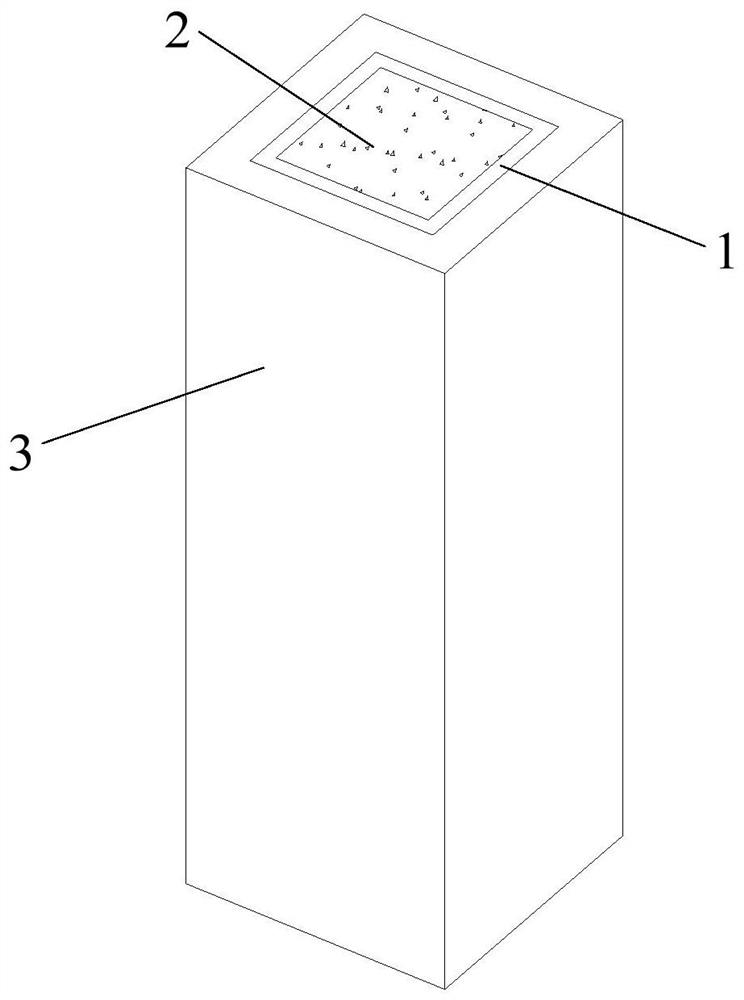

[0021] Please check Figure 1-2 , a construction device for maintaining ultra-high performance steel pipe 1 concrete column 2 at room temperature in this embodiment, including concrete column 2, steel pipe 1, and insulation layer 3;

[0022] The thermal insulation layer 3 is a layer of high foamed polyethylene material, which is sealed on the outer periphery of the steel pipe 1;

[0023] The interior of the steel pipe 1 is filled with concrete columns 2, and the temperature inside the steel pipe 1 is 70-90°C;

[0024] The concrete column 2 is composed of water, cement, silica fume, quartz powder, polycarboxylate superplasticizer, quartz sand and sodium polyacrylate in a mass ratio of 0.2:1:0.15:0.2:0.009:1.75:0.03 It is mixed; the sodium polyacrylate added in the component can absorb 15-30 times of its own weight of water during the concrete mixing process, providing sufficient hydration water for the concrete in the early stage of curing. The polycarboxylate-based high-perf...

Embodiment 2

[0027] Adopt embodiment 1 device to carry out the method for maintenance construction, may further comprise the steps:

[0028] 1) Mix water, cement, silica fume, quartz powder, polycarboxylate superplasticizer, quartz sand and sodium polyacrylate in a mass ratio of 0.2:1:0.15:0.2:0.009:1.75:0.03, and put in In the concrete mixer, stir for 15 to 20 minutes to obtain finished concrete;

[0029] 2) Pour the finished concrete into the steel pipe 1, vibrate for 1-2 minutes every time one-third of the height of the steel pipe 1 is poured, until all the pouring is completed;

[0030] 3) Maintain the temperature of the steel pipe 1 and the finished concrete at 70-90°C, uniformly cover the steel pipe 1 with a layer of high foamed polyethylene as the insulation layer 3, and use glue to bond the high foamed polyethylene insulation layer 3 and the steel pipe 1 together , when the insulation layer 3 is bonded and sealed, it is bonded under slight extrusion, so that the bonding surfaces o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com