Production device and manufacturing method for preparing granular fuel by mixing sanding powder and rice hulls

A technology of pellet fuel and manufacturing method, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of poor moldability and fuel characteristics of molded fuel, substandard pollutant emission, and incompatibility of combustion mode, etc., so as to improve the moldability. , the effect of energy shortage alleviation and improvement of briquette fuel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

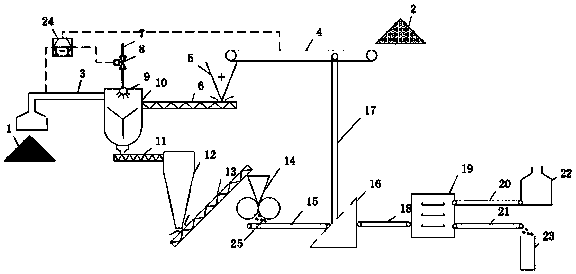

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0027] A method for preparing granular fuel by mixing sanding powder with rice husks, comprising the following steps: a. collecting sanding powder 1, crushing rice husks 2 to form rice husk powder;

[0028] b. Sanding powder 1 is mixed with rice husk powder for stirring and humidification;

[0029] c, sanding powder 1 and rice husk powder stand still and homogeneous;

[0030] d, the mixture of sanding powder 1 and rice husk powder is made into granular fuel 25;

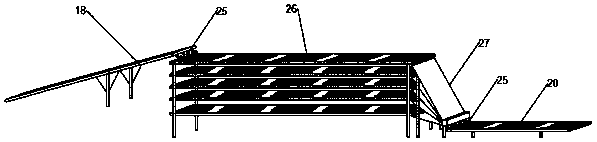

[0031] e, sieving and grading the formed mixture;

[0032] f. Air-dry and dehumidify the qualified mixture after sieving and grading.

[0033]Further, in step a: the sanding powder 1 is collected and conveyed into the mixing tank 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com