White vinegar and production method thereof

A production method and technology for white vinegar, applied in the field of vinegar, can solve problems such as reducing pigments, and achieve the effects of positive acidity, bright color and good anti-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

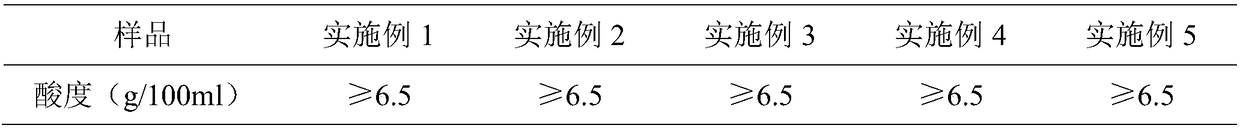

Examples

Embodiment 1

[0032] The production method of the white vinegar of the present embodiment, comprises the following steps:

[0033] 1) Take fermentation raw materials, including 80 parts of rice, 10 parts of glutinous rice, 4 parts of peas, and 6 parts of millet. The fermented raw materials are respectively pulverized and uniformly mixed to obtain fermented raw material powder. The fermented raw material powder is mixed evenly with water, and at the same time, isovitamin C is added to adjust the slurry to obtain the fermented raw material slurry. The mass ratio of water to fermentation raw material powder is 6:1. The added amount of isovitamin C accounts for 0.05% of the mass of fermentation raw material powder.

[0034] 2) adding amylase to the fermentation raw material slurry in step 1) for liquefaction to obtain liquefied mash. The amount of amylase added is 20U per g of fermentation raw material powder. During the reaction process, through dilute iodine solution experiment, when the ...

Embodiment 2

[0040] The production method of the white vinegar of the present embodiment, comprises the following steps:

[0041] 1) Take fermentation raw materials, including 75 parts of rice, 15 parts of glutinous rice, 5 parts of peas, and 5 parts of millet. The fermented raw materials are respectively pulverized and uniformly mixed to obtain fermented raw material powder. The fermented raw material powder is mixed evenly with water, and at the same time, sodium isovitamin C is added to adjust the slurry to obtain the fermented raw material slurry. The mass ratio of water to fermentation raw material powder is 6:1. The amount of sodium isovitamin C added accounts for 0.08% of the mass of the fermentation raw material powder.

[0042] 2) adding amylase to the fermentation raw material slurry in step 1) for liquefaction to obtain liquefied mash. The amount of amylase added is 20U per g of fermentation raw material powder. During the reaction process, through dilute iodine solution exp...

Embodiment 3

[0049] The production method of the white vinegar of the present embodiment, comprises the following steps:

[0050] 1) Take fermentation raw materials, including 20 parts of rice, 50 parts of glutinous rice, 30 parts of peas, and 1 part of millet. The fermented raw materials are respectively pulverized and uniformly mixed to obtain fermented raw material powder. The fermented raw material powder is mixed evenly with water, and at the same time, isovitamin C is added to adjust the slurry to obtain the fermented raw material slurry. The mass ratio of water to fermentation raw material powder is 4:1. The added amount of isovitamin C accounts for 0.1% of the mass of fermentation raw material powder.

[0051] 2) adding amylase to the fermentation raw material slurry in step 1) for liquefaction to obtain liquefied mash. The amount of amylase added is 10U per g of fermentation raw material powder. During the reaction process, through dilute iodine solution experiment, when the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com