A kind of multilayer polyolefin microporous membrane with asymmetric structure and its preparation method and application

A polyolefin microporous membrane, asymmetric technology, applied in the direction of structural parts, electrical components, battery components, etc., can solve the problems of poor mechanical properties of the diaphragm, low wettability of the electrolyte, and flow marks on the appearance of the membrane surface, etc., to achieve Rough film surface, reduce or avoid tearing phenomenon, good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

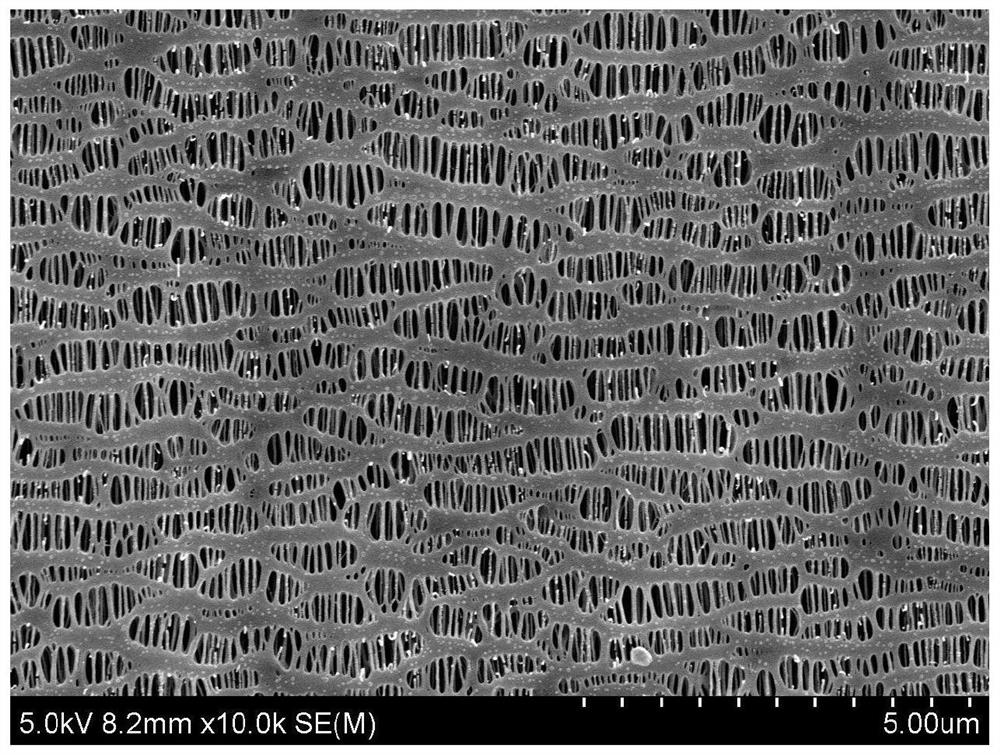

Embodiment 1

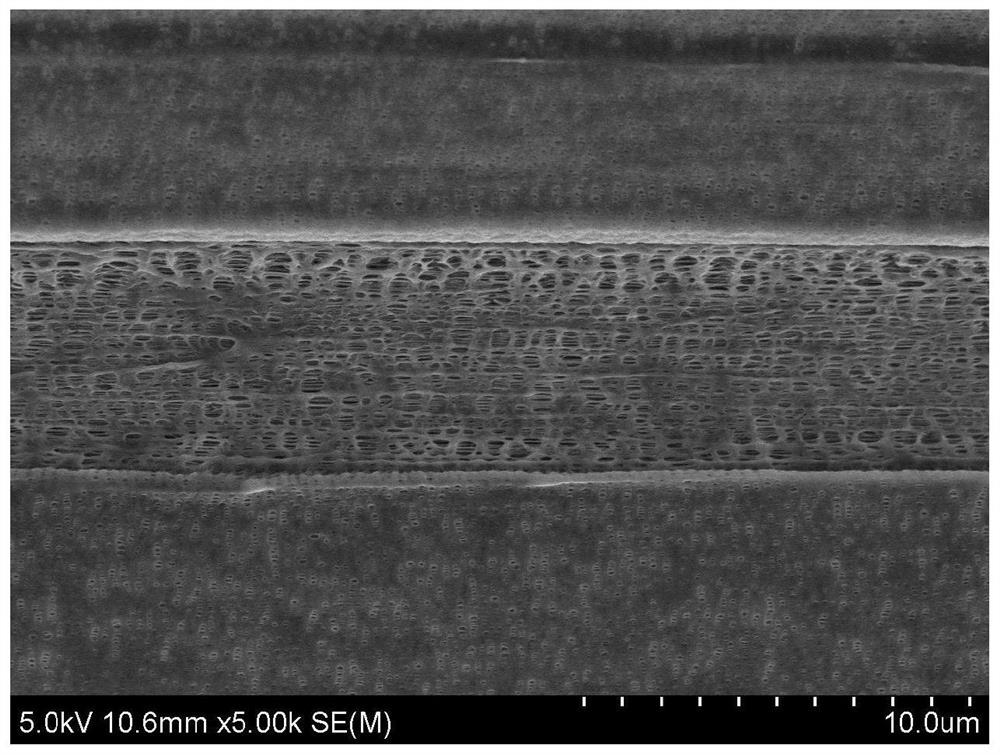

[0037] The multilayer polyolefin microporous membrane with asymmetric structure in this example is composed of A film layer, B film layer and C film layer, with a total thickness of 16 microns. Among them, the A film layer is polypropylene with a high melt index, its melt index is 3.0g / 10min, and its weight average molecular weight is 3×10 5 ;B film layer has a melt index of 0.5g / 10min and a weight average molecular weight of 2×10 5 Polyethylene; C film layer has a melt index of 0.5g / 10min and a weight average molecular weight of 6×10 5 of polypropylene. The thickness ratio of A film layer, B film layer and C film layer is 1:1:1.

[0038] The multilayer polyolefin microporous membrane of this example, concrete preparation method is as follows:

[0039] (1) Casting extrusion: Add the raw materials of A film layer, B film layer and C film layer into three extruders respectively for melting and plasticizing extrusion, wherein, A film layer, B film layer and C film layer The p...

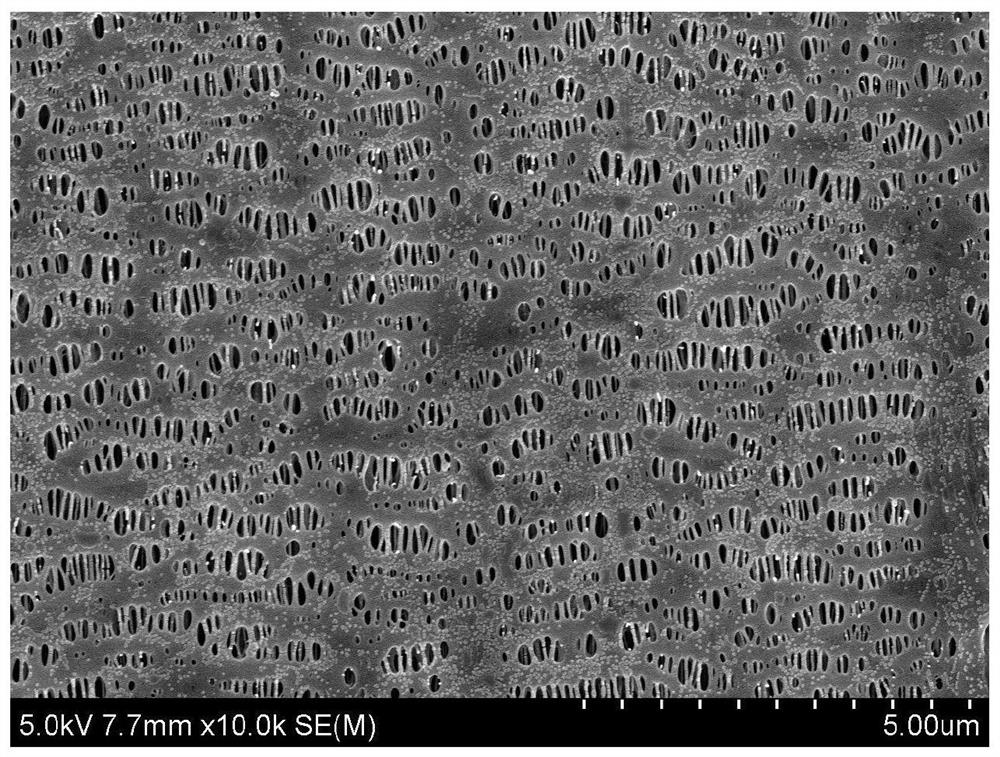

Embodiment 2

[0045] The multilayer polyolefin microporous membrane of this example has the same structure and preparation method as in Example 1. The difference is that the A film layer of this example adopts a melting index of 6.0g / 10min and a weight average molecular weight of 2×10 5 The polypropylene, all the other are identical with embodiment 1.

Embodiment 3

[0047] The multilayer polyolefin microporous membrane of this example has the same structure and preparation method as Example 1, but the difference is that the C film layer of this example adopts a melting index of 1.0g / 10min and a weight average molecular weight of 4.5×10 5 The polypropylene, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com