Novel method for treating surplus ammonia water by coking dedusted coke powder

A technology of coke powder and ammonia water, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as high energy consumption, difficult treatment of biochemical wastewater, and raw materials for adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

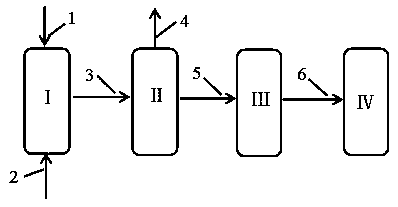

[0024] The specific implementation is as figure 1 In the device process shown, the residual ammonia water of the coking enterprise and the dedusted coke powder collected in the coking production process are sent to the reaction tank, stirred and mixed; the dedusted coke powder is directly sent into the reaction tank by pneumatic conveying, and the particle size Distributed at 0.1-0.5mm, the ratio of residual ammonia water volume to dedusted coke powder mass ratio during adsorption treatment is 40:1 (m 3 / t); the remaining ammonia water after mixed adsorption treatment in the reaction tank is separated by a centrifuge to remove the mixed wet dedusting coke powder in the remaining ammonia water; the remaining ammonia water after centrifugation is sent to the automatic backwash filter; the remaining ammonia water after the filter The ammonia water is sent to the ammonia distillation process.

[0025] After treatment, the removal rate of COD is 35-40%, the removal rate of sulfide...

Embodiment 2

[0027] The specific implementation is as figure 1 In the device process shown, the residual ammonia water of the coking enterprise and the dedusted coke powder collected in the coking production process are sent to the reaction tank, stirred and mixed; the dedusted coke powder is directly sent into the reaction tank by pneumatic conveying, and the particle size Distributed at 0.1-0.5mm, the ratio of residual ammonia water volume to dedusted coke powder mass ratio during adsorption treatment is 40:1 (m 3 / t); the remaining ammonia water after mixed adsorption treatment in the reaction tank is separated by a centrifuge to remove the mixed wet dedusting coke powder in the remaining ammonia water; the remaining ammonia water after centrifugation is sent to the automatic backwash filter; the remaining ammonia water after the filter The ammonia water is sent to the ammonia distillation process.

[0028] After treatment, the removal rate of COD is 35-40%, the removal rate of sulfide...

Embodiment 3

[0031] The specific implementation is as figure 1 In the device process shown, the residual ammonia water of the coking enterprise and the dedusted coke powder collected in the coking production process are sent to the reaction tank, stirred and mixed; the dedusted coke powder is directly sent into the reaction tank by pneumatic conveying, and the particle size Distributed at 1.0-1.5mm, the ratio of residual ammonia water volume to dedusted coke powder mass ratio during adsorption treatment is 70:1 (m 3 / t); the remaining ammonia water after mixed adsorption treatment in the reaction tank is separated by a centrifuge to remove the mixed wet dedusting coke powder in the remaining ammonia water; the remaining ammonia water after centrifugation is sent to the automatic backwash filter; the remaining ammonia water after the filter The ammonia water is sent to the ammonia distillation process.

[0032] After treatment, the removal rate of COD is 30-35%, the removal rate of sulfide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com