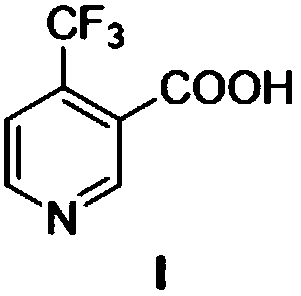

Method for preparing 4-(trifluoromethyl)nicotinic acid

A technology of trifluoromethyl nicotinic acid and trifluoroacetyl chloride, which is applied in the field of chemical drug intermediate preparation, can solve the problems of difficult industrialized production, long process route, low total yield and the like, and achieves strong market competitiveness and method. Simple operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

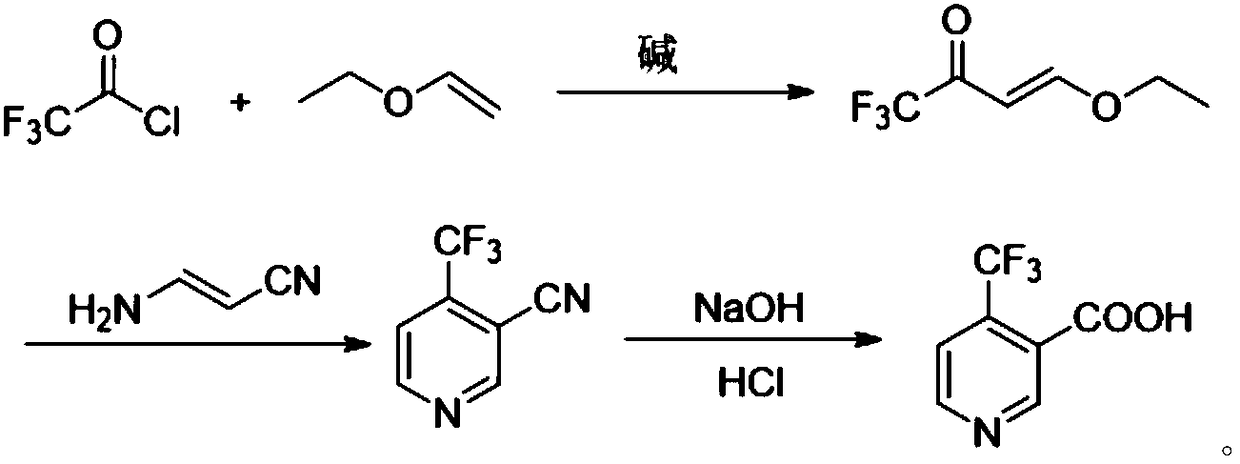

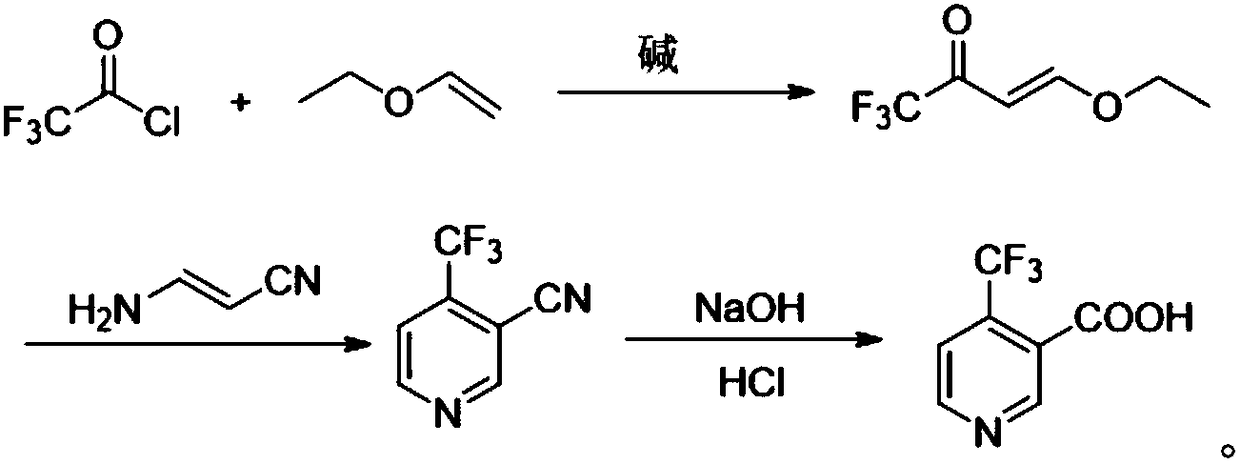

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of 4-ethoxy-1,1,1-trifluoro-3-en-2-one.

[0023] In a 1000mL airtight four-necked reaction flask, add 72.1g of vinyl ether, 87.0g of pyridine and 500mL of toluene, stir evenly, control the temperature at 10-15°C, slowly add 145.8g of trifluoroacetyl chloride dropwise, and the dropping time lasts for 1 hour , after the dropwise addition was completed, the stirring was continued for 3 hours, the reaction was completed, and 300 mL of ice water was added to the reaction system to quench, the organic phase was washed twice with saline, and the solvent toluene was distilled off under reduced pressure to obtain a light yellow liquid 4-ethoxy-1 , 1,1-trifluoro-3-en-2-one 115.2 g, yield 68.5%.

Embodiment 2

[0024] Example 2: Preparation of 4-ethoxy-1,1,1-trifluoro-3-en-2-one.

[0025] In a 1000mL airtight four-necked reaction flask, add 72.1g of vinyl ether, 87.0g of pyridine and 500mL of toluene, stir evenly, control the temperature at 0-5°C, slowly add 145.8g of trifluoroacetyl chloride dropwise, and the dropping time lasts for 1 hour , after the dropwise addition was completed, the stirring was continued for 3 hours, the reaction was completed, and 300 mL of ice water was added to the reaction system to quench, the organic phase was washed twice with saline, and the solvent toluene was distilled off under reduced pressure to obtain a light yellow liquid 4-ethoxy-1 , 1,1-trifluoro-3-en-2-one 145.7 g, yield 86.7%.

Embodiment 3

[0026] Example 3: Preparation of 4-ethoxy-1,1,1-trifluoro-3-en-2-one.

[0027] In a 1000mL airtight four-necked reaction flask, add 72.1g of vinyl ether, 87.0g of pyridine and 500mL of toluene, stir evenly, control the temperature at 0-5°C, and slowly add 159.0g of trifluoroacetyl chloride dropwise for 1 hour , after the dropwise addition was completed, the stirring was continued for 3 hours, the reaction was completed, and 300 mL of ice water was added to the reaction system to quench, the organic phase was washed twice with saline, and the solvent toluene was distilled off under reduced pressure to obtain a light yellow liquid 4-ethoxy-1 , 1,1-trifluoro-3-en-2-one 155.2 g, yield 92.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com