Method for purifying cetrorelix

A technology of cetrorelix and purification method, which is applied in the fields of peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problem that cetrorelix has no obvious separation effect, achieve purification yield and stable, and produce The process is simple, the method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

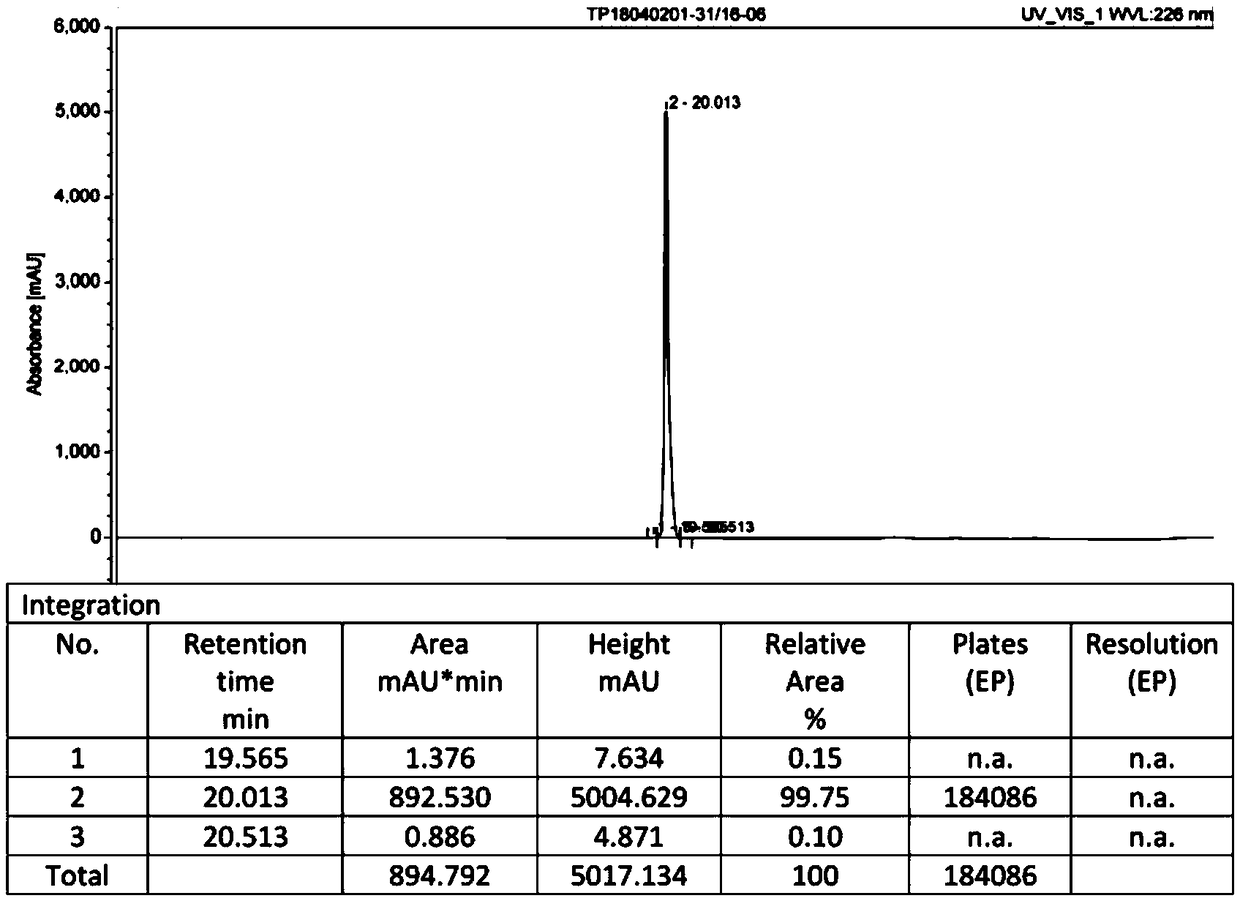

[0029] Take the crude cetrorelix peptide, add 5% acetonitrile solution, dissolve, stir, and sonicate, the content of cetrorelix in the solution is 15 mg / ml. When the solution was clear, it was filtered with a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A 3.0×250mm C18 / C8 reverse-phase silica gel column was used. The mobile phase A is a mixed aqueous solution of 0.5wt% sodium sulfate and 0.5% v / v trifluoroacetic acid, the mobile phase B is 100% acetonitrile solution, and the solution storing the mobile phase is put into a water bath and heated to 30-50°C. The pretreatment of the chromatographic column is to use a high-concentration organic phase to remove impurities, and then use an organic phase with a concentration lower than 25% to balance. The volume of the crude peptide sample on pump A is 20ml, and then gradient elution is performed with mobile phase A and mobile phase B, and the flow rate is controlled at 20ml / min. The elu...

Embodiment 2

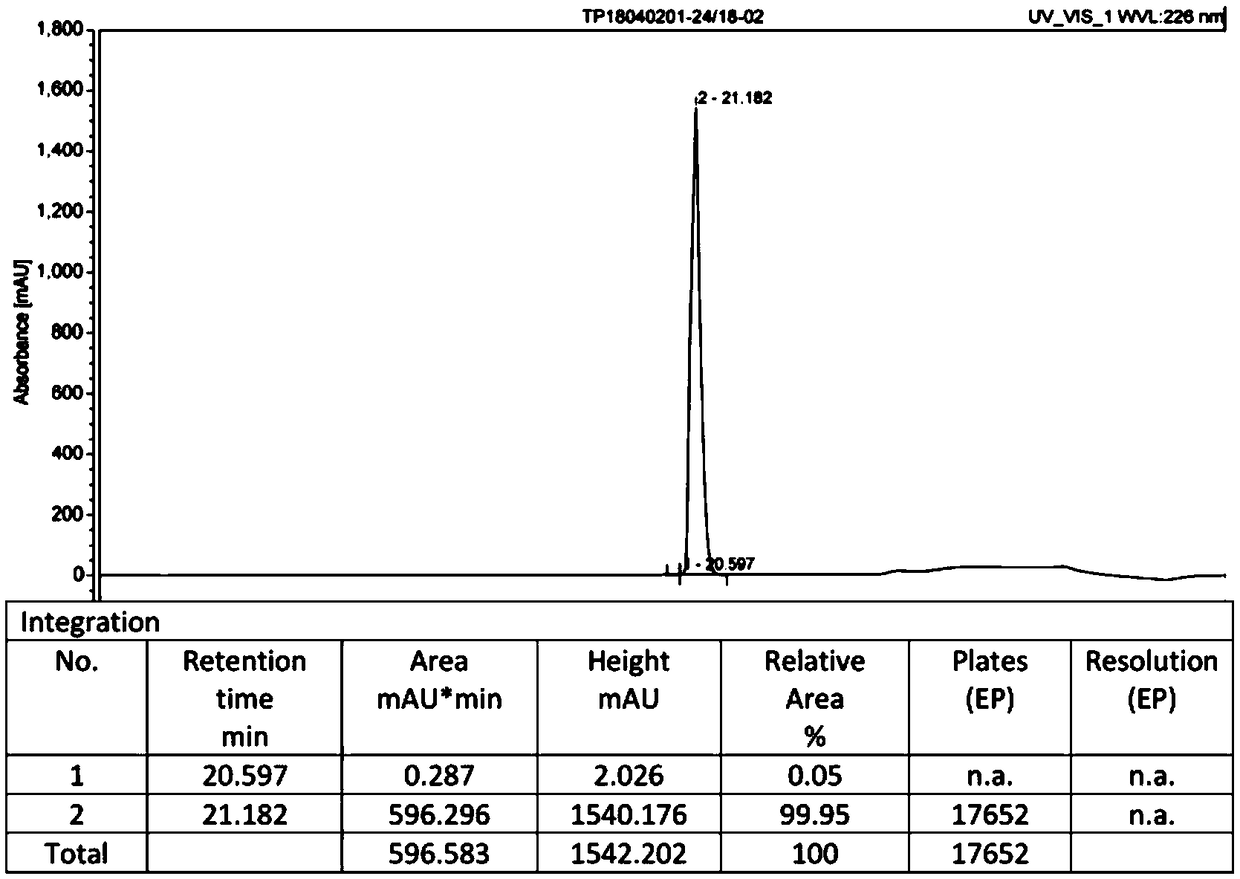

[0031] Take the crude cetrorelix peptide, add 5% acetonitrile solution, dissolve, stir, and sonicate, the content of cetrorelix in the solution is 15 mg / ml. When the solution was clear, it was filtered with a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A 3.0×250mm C18 silica gel column for reverse phase chromatography was used. The mobile phase A is a mixed aqueous solution of 4wt% sodium sulfate and 2% v / v trifluoroacetic acid, the mobile phase B is a 100% acetonitrile solution, and the solution storing the mobile phase is put into a water bath and heated to 30-50°C. The pretreatment of the chromatographic column is to use a high-concentration organic phase to remove impurities, and then use an organic phase with a concentration lower than 25% to balance. The volume of the crude peptide sample on pump A is 20ml, and then gradient elution is performed with mobile phase A and mobile phase B, and the flow rate is controlled at 20ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com