Quantum dots, fabrication methods, single photon sources and qleds

A production method and quantum dot technology, applied in the field of optoelectronics, can solve the problems of low luminous efficiency of devices, and achieve the effect of high reliability and stable devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

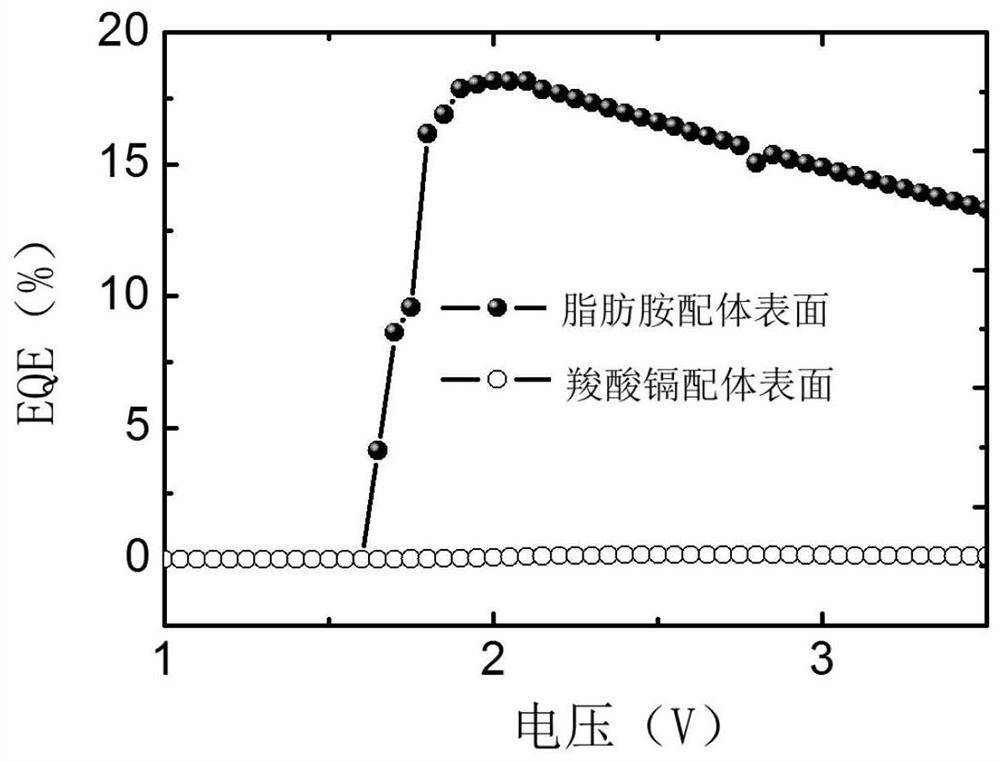

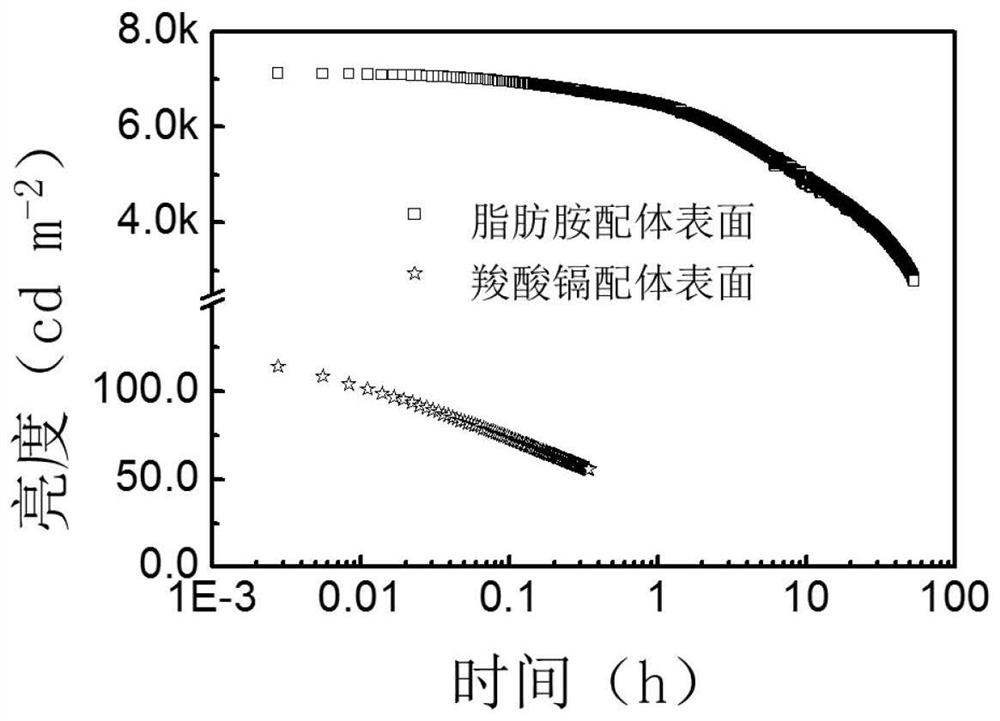

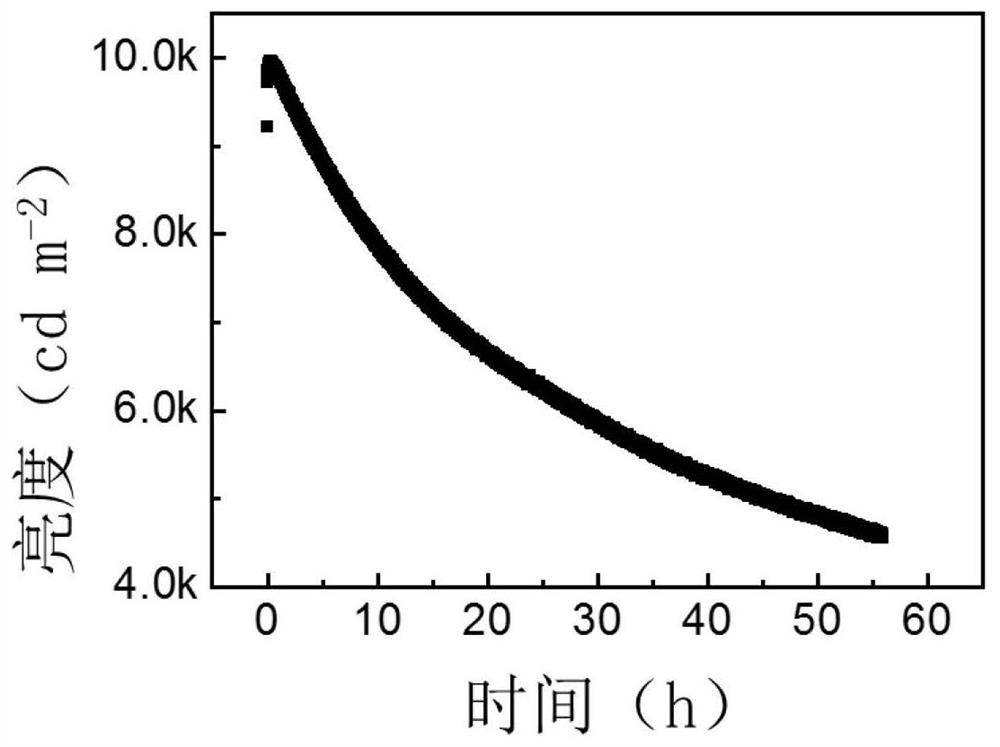

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The fabrication process of quantum dots includes:

[0067] First make the preparation of quantum dots, which are quantum dots with a core-shell structure, specifically red CdSe / CdS core-shell quantum dots. The synthesis process includes:

[0068] Weigh 0.2 mmol of cadmium oxide, 0.6 mmol of stearic acid and 3 mL of ODE, mix them, and heat to 260° C. to dissolve.

[0069] Inject 1mL*0.1mol of selenium powder-ODE suspension into the solution formed in the upward step, and after 8 minutes, inject 0.05mL*0.1mol of selenium powder-ODE suspension every 3 minutes until the CdSe quantum dot grows to the required size (the first exciton absorption peak is at 550nm), the original reaction solution was obtained.

[0070] Purification of CdSe nuclear quantum dots: Take 1 mL of the original reaction solution, add 2 mL of acetone and 0.5 mL of methanol, heat and centrifuge, and pour off the supernatant. Dissolve the precipitate with 1 mL of toluene, add 1 mL of methanol, heat and c...

Embodiment 2

[0077] The difference from Example 1 is that the modifying agent is n-octylamine.

Embodiment 3

[0079] The difference from Example 2 is: the preparation of quantum dots is red CdSe / CdZnS quantum dots, and its synthesis process includes:

[0080] Weigh 0.2 mmol of cadmium oxide, 0.6 mmol of stearic acid and 3 mL of ODE, mix them, and heat to 260° C. to dissolve.

[0081] Inject 1mL*0.1mol of selenium powder-ODE suspension into the solution formed in the upward step, and after 8 minutes, inject 0.05mL*0.1mol of selenium powder-ODE suspension every 3 minutes until the CdSe quantum dot grows to the required size (the first exciton absorption peak is at 550nm), the original reaction solution was obtained.

[0082] Purification of CdSe nuclear quantum dots: Take 1 mL of the original reaction solution, add 2 mL of acetone and 0.5 mL of methanol, heat and centrifuge, and pour off the supernatant. Dissolve the precipitate with 1 mL of toluene, add 1 mL of methanol, heat and centrifuge. This step was repeated 2 times.

[0083] Take 3mmol of zinc acetate, 0.3mmol of cadmium acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com