A method for preparing highly crystalline nano nitride phosphor

A nitride phosphor, high crystallinity technology, applied in nano optics, chemical instruments and methods, nanotechnology, etc., can solve the problems of decreased luminous efficiency, difficult to accurately control the packaging process, low yield rate, etc., to eliminate light loss , Improve light extraction efficiency, crystallinity recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

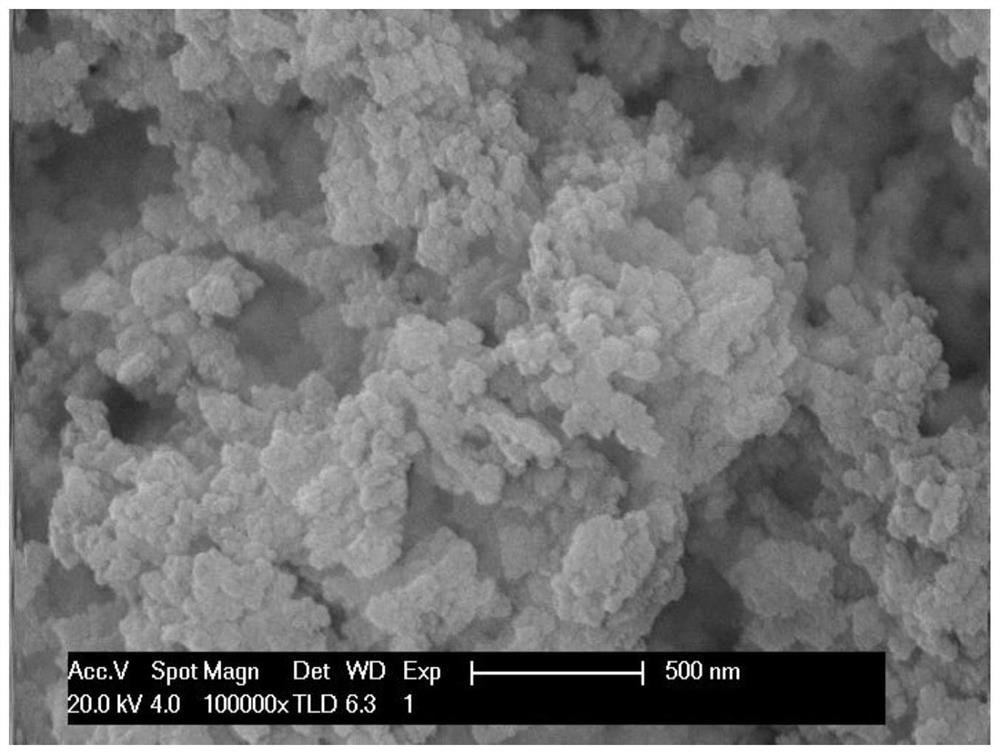

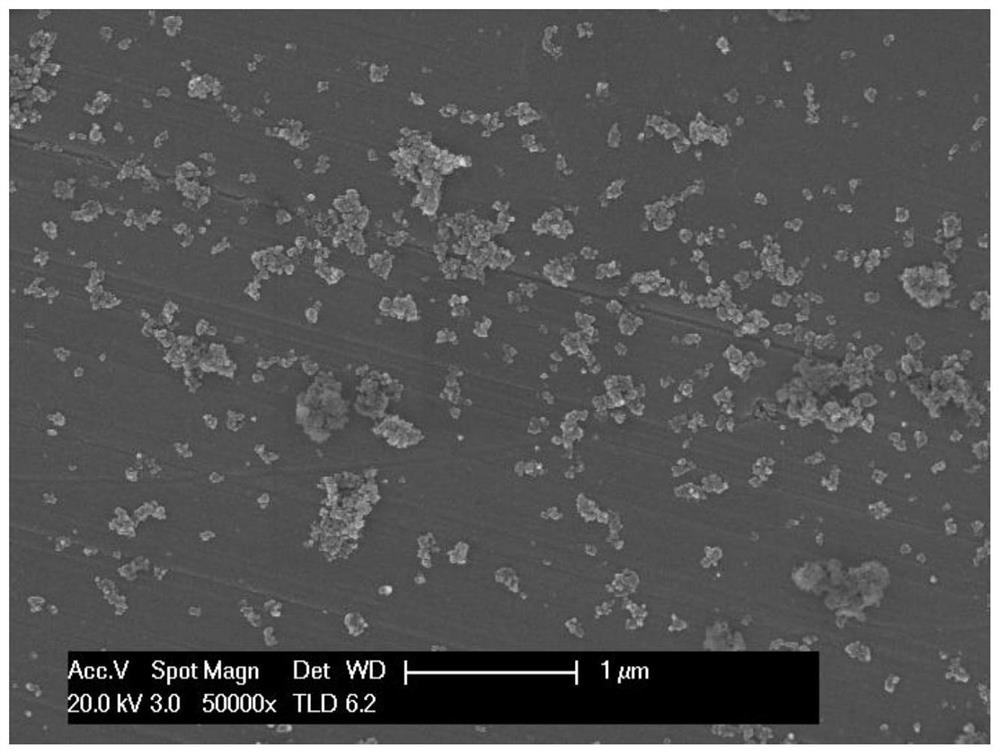

Embodiment 1

[0042] Example 1: Prepare 2 L of potassium sulfate solution with a concentration of 0.1 mol / L with deionized water, add polyacrylic acid with a salt mass of 5%, and dissolve it. The potassium sulfate solution containing polyacrylic acid is dropped into 50 liters of ethanol under the condition of stirring, the precipitate is washed with ethanol for 1-2 times, and the potassium sulfate nano crystal can be obtained after drying. Weigh 10 grams of nano-potassium sulfate, disperse it in 200 ml of ethanol, add 0.5 grams of stearic acid, and keep stirring at 50° C. for 2 hours. After centrifuging the nano-potassium sulfate ethanol dispersion, disperse the nano-potassium sulfate in 100ml xylene, add 10g of nano-CaAlSiN obtained by mechanical pulverization 3 : Eu phosphor, stirred at 80°C for 2 hours, centrifuged, dried, calcined at 1000°C in a nitrogen atmosphere for 2 hours, washed with water, dried to obtain highly crystalline dispersed nano-CaAlSiN 3 : Eu phosphor.

Embodiment 2

[0043] Example 2: Prepare 2 L of potassium sulfate solution with a concentration of 0.1 mol / L with deionized water, add polyacrylic acid with a salt mass of 5%, and dissolve it. The potassium sulfate solution containing polyacrylic acid is dropped into 50 liters of ethanol under the condition of stirring, the precipitate is washed with ethanol for 1-2 times, and the potassium sulfate nano crystal can be obtained after drying. Weigh 1 gram of nanopotassium sulfate, disperse it in 200ml of ethanol, add 0.01 gram of stearic acid, and keep stirring at 50°C for 2 hours. After centrifuging the nano-potassium sulfate ethanol dispersion, disperse the nano-potassium sulfate in 100ml xylene, add 0.1g of nano-CaAlSiN obtained by mechanical pulverization 3 : Eu phosphor, stirred at 80°C for 2 hours, centrifuged, dried, calcined at 1000°C in a nitrogen atmosphere for 2 hours, washed with water, dried to obtain highly crystalline dispersed nano-CaAlSiN 3 : Eu phosphor.

Embodiment 3

[0044] Example 3: Prepare 2 L of potassium sulfate solution with a concentration of 0.1 mol / L with deionized water, add polyacrylic acid with a salt mass of 5%, and dissolve it. The potassium sulfate solution containing polyacrylic acid is dropped into 50 liters of ethanol under the condition of stirring, the precipitate is washed with ethanol for 1-2 times, and the potassium sulfate nano crystal can be obtained after drying. Weigh 5 grams of nano-potassium sulfate, disperse it in 200 ml of ethanol, add 0.1 gram of stearic acid, and keep stirring at 50° C. for 2 hours. After centrifuging the nano-potassium sulfate ethanol dispersion, disperse the nano-potassium sulfate in 100ml xylene, add 5g of nano-CaAlSiN obtained by mechanical pulverization 3 : Eu phosphor, stirred at 80°C for 2 hours, centrifuged, dried, calcined at 1000°C in a nitrogen atmosphere for 2 hours, washed with water, dried to obtain highly crystalline dispersed nano-CaAlSiN 3 : Eu phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com