Production process for brewing mature vinegar from glutinous sorghum

A production process, the technology of aged vinegar, applied in the preparation of vinegar, microorganisms, methods based on microorganisms, etc., can solve the problems of sticking and agglomeration, the production process of glutinous sorghum brewing mature vinegar, etc., to ensure activity and prolong alcohol Fermentation cycle, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

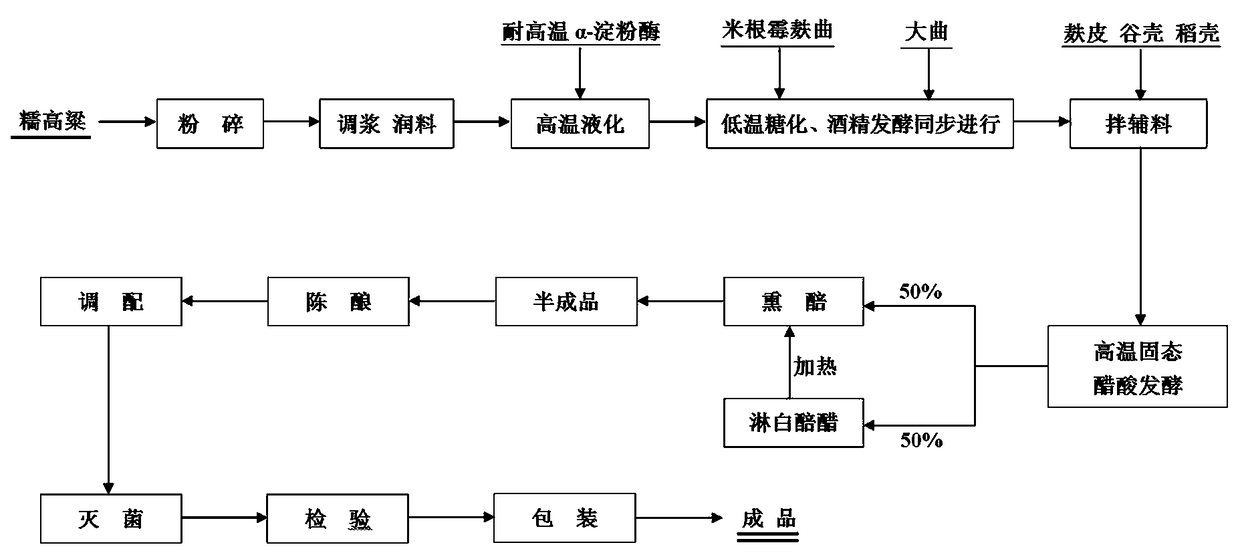

[0029] A kind of production technology of glutinous sorghum brewing mature vinegar, such as figure 1 shown, including the following steps:

[0030] 1. Preparation of rhizopus bran koji

[0031] 1.1. Preparation of Rhizopus seed koji: Take 200g of bran and put it in a conical flask, add 140g~160g of water, mix and spread evenly, the thickness is 5~10mm, and autoclave for 30min. After cooling, insert Rhizopus oryzae AS3.866 and place it in an incubator at 28-32°C for 48-60 hours. When the mycelium is covered and the bran is connected to form a cake, buckle the bottle (invert the triangular flask with the mouth of the bottle facing down) and continue the cultivation. Take it out to dry after a day.

[0032] 2. Preparation of rhizopus bran koji: Take 10kg of bran, add 6kg~7kg of water, stir and disperse evenly, cook under normal pressure for 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com