A kind of preparation method of anode plate for electrolytic manganese dioxide

A technology of electrolytic manganese dioxide and anode plate, applied in the direction of electrodes, electrolytic components, electrolysis process, etc., can solve the problems of anode strip shape distortion, not in one plane, affecting electrolysis process, etc., achieve stable geometry, increase production, The effect of high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

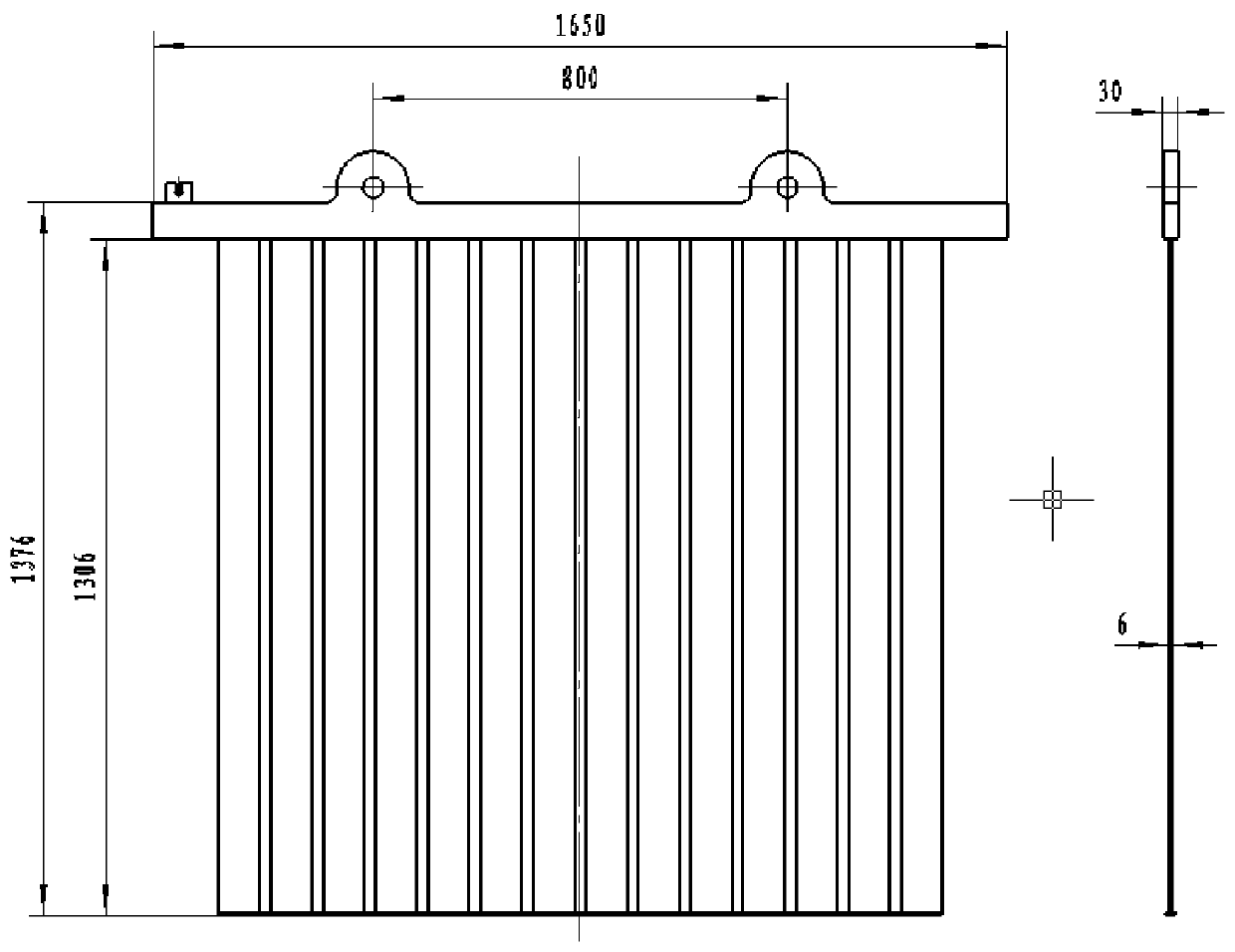

[0021] The metal mixed powder components are titanium and manganese, and the weight percentages of each component are as follows: titanium: 50%, manganese: 50%, the metal powder is mixed with polyvinyl alcohol glue to form a slurry, and the slurry is placed in the spray gun storage tank, passed High-pressure gas pressurizes, sprays out from the gun nozzle, and finally evenly adheres to the surface of the titanium strip.

[0022] The surface of the titanium plate coated with metal mixed powder slurry is placed in a normal temperature vacuum storage tank after natural drying, and the vacuum is evacuated to 10 -3 After Pa is filled with argon gas protection, and then pulled, the titanium plate coated with metal powder on the surface is heated through a constant temperature heating furnace (furnace temperature 1300°C) located directly above the vacuum storage tank, and the pulling speed is 10cm / min. After that, it is quickly pulled to the cold well directly above the constant temp...

Embodiment 2

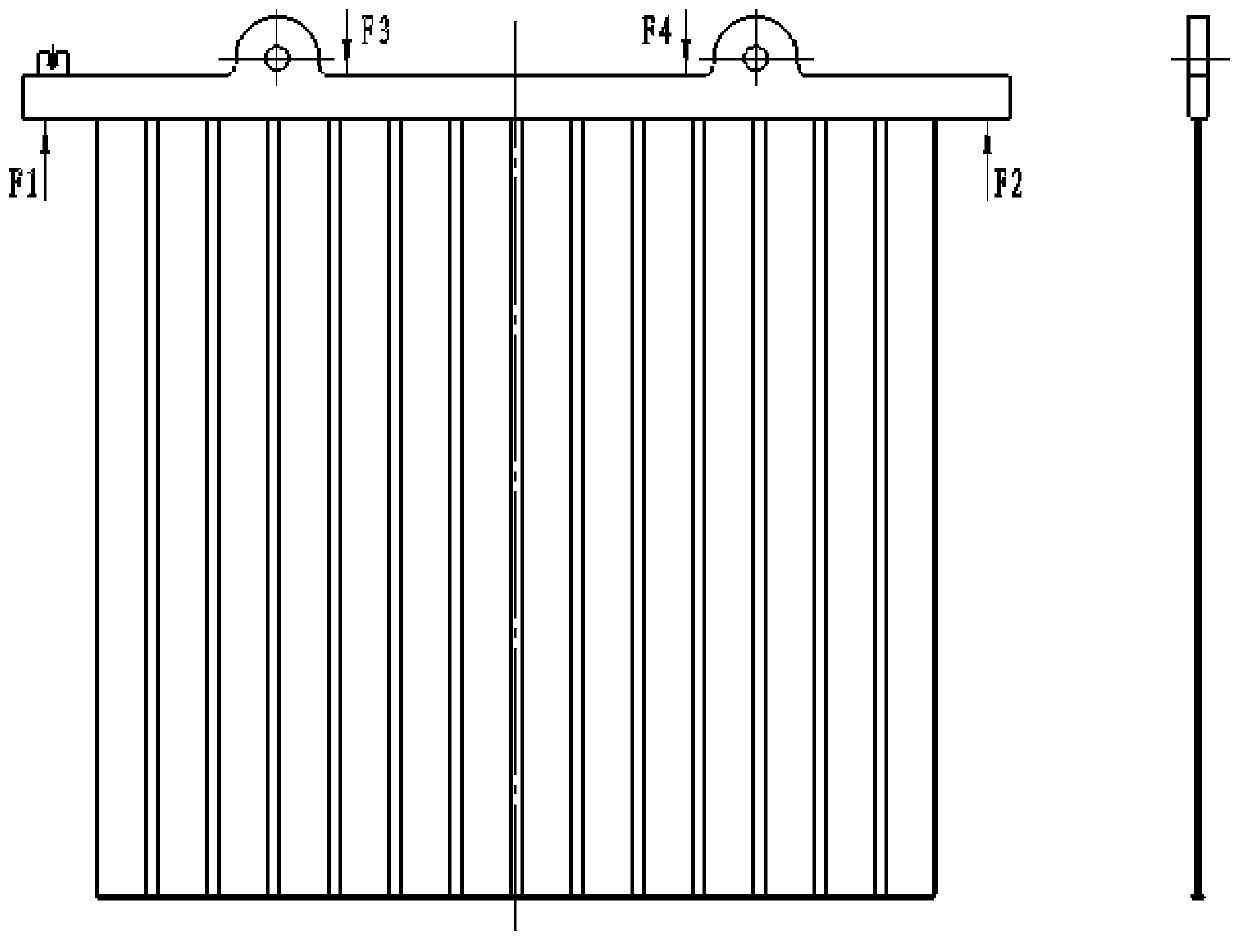

[0032] The other process conditions are the same as in Example 1. The cast aluminum cross arm of the anode plate is vertically suspended on the detection frame, and the deformation amount is determined according to the offset amount corresponding to the detection scale, and the deformation amount is within ±25mm.

[0033] Place the anode plate on the shaping platform, apply an external force consistent with the previous deformation, and refer to the attached figure 2. In the figure: F1 and F2 are the adjustment external forces applied to both ends of the cast aluminum cross-arm; F3 and F4 are the external forces applied to the cast aluminum cross-arm by the shaping platform. The method of applying external force at four points of the cast aluminum cross arm is used to achieve the expected deformation. Finally, hang the anode plate on the detection frame again to detect the deformation. If the deformation is within ±3mm, the correction and shaping will be completed; if the def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com