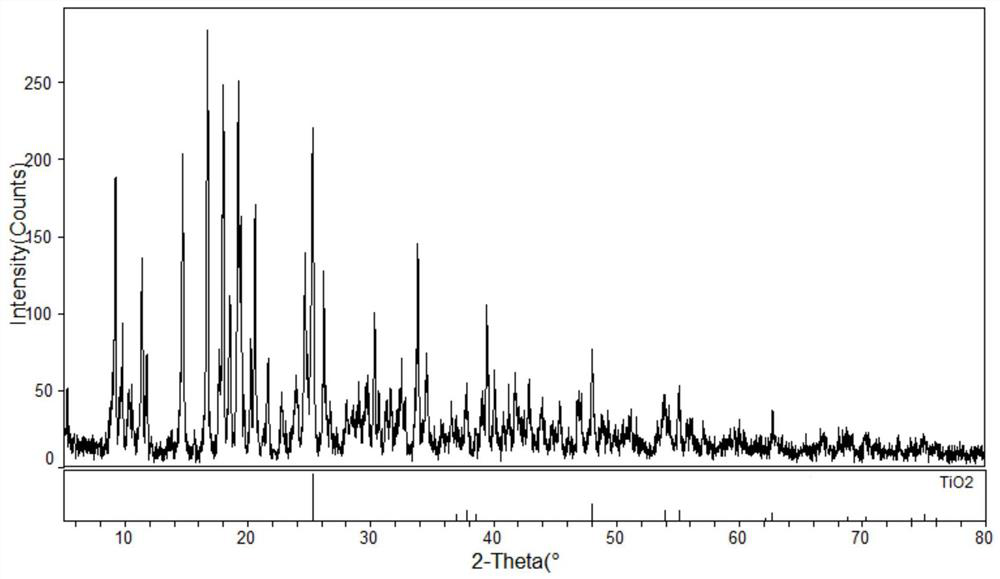

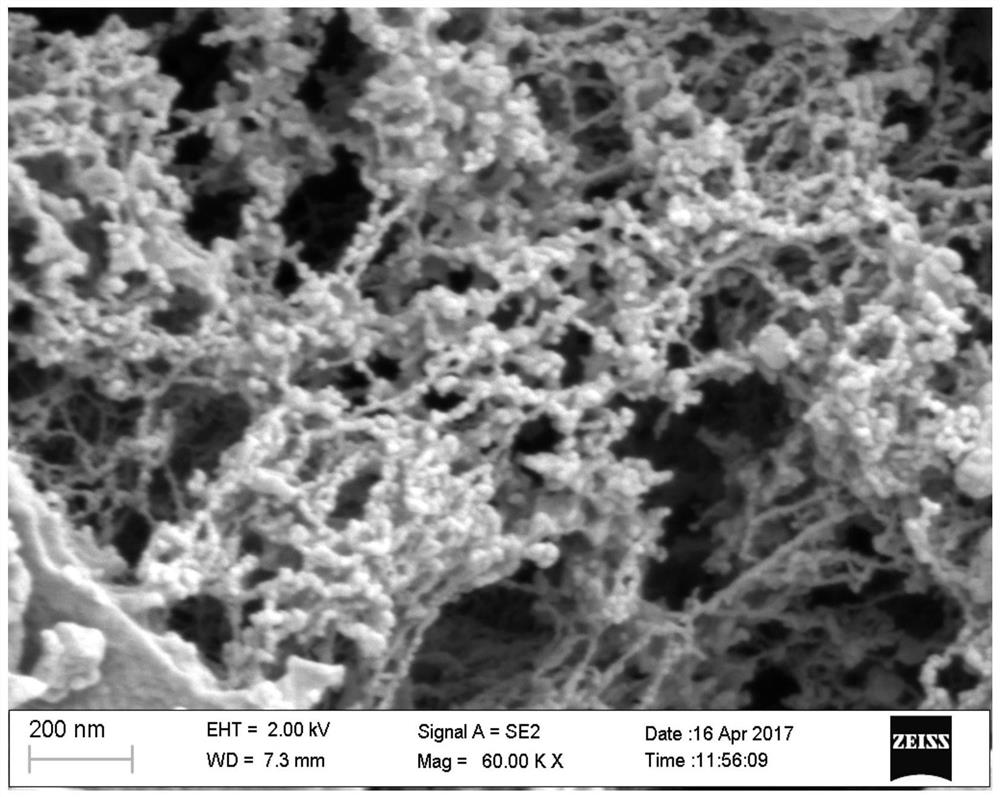

tio 2 Preparation method of /mof-5 composite photocatalyst

A MOF-5, composite light technology, applied in the field of photocatalysis, can solve the problem of difficult loading of MOF-5, and achieve the effect of improving the catalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention provides a kind of TiO 2 The preparation method of / MOF-5 composite photocatalyst comprises the following steps:

[0026] S10, add triethylamine to the mixed solution of soluble zinc salt, terephthalic acid and the first organic solvent, deprotonate terephthalic acid and self-assemble with zinc ions to form MOF-5, filter, wash, dry and grind to obtain MOF-5 powder;

[0027] S20, causing the hydrolyzable titanium source to undergo a hydrolysis reaction with water in a second organic solvent to obtain a first solution containing nano-titanium dioxide sol;

[0028] S30, concentrating the first solution, increasing the concentration of the nano-titanium dioxide sol, to obtain a second solution; and

[0029] S40, adding the MOF-5 powder to the second solution, thoroughly mixing by ultrasonic vibration, filtering, washing and drying to obtain TiO 2 / MOF-5 composite photocatalyst.

[0030] TiO provided by the invention 2 / MOF-5 compo...

Embodiment 1

[0049] S10, first add 1.21g of Zn(NO 3 ) 2 ·6H 2 O and 40ml N,N-dimethylformamide (DMF) were placed in a beaker, then 0.34g terephthalic acid (H 2 BDC) into the beaker, stirring constantly, after the solid is completely dissolved, then add 1.3mL triethylamine TEAC into the mixed solution, stirring constantly, react for about 3h, filter with suction, wash with DMF for 3-4 Once, unreacted inorganic salts and organic acids were removed to obtain a white solid. Finally, the white solid was dried in an oven. After drying, it was ground into powder to obtain MOF-5 powder.

[0050] S22, take 20ml of absolute ethanol and add it to a clean and dry flask, drop 4 drops of 0.2ml glacial acetic acid with a rubber dropper, and stir it magnetically for 5 minutes; take 2ml tetrabutyl titanate and add it to the above mixture, and stir it magnetically for 5 minutes; Slowly add 38ml of deionized water dropwise while stirring. The dropwise addition time is more than 15min. After the dropwise...

Embodiment 2

[0055] The preparation method is basically the same as that of Example 1, except that in step S30, 1 / 2 of the volume of the first solution is evaporated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com