Preparation method of electronic grade 1,3-propane sultone

A propane sultone, electronic-grade technology, applied in the field of organic compound preparation, can solve the problems of affecting product quality, difficult to realize industrialization, complicated process operation, etc., and achieves stable and controllable operation process, low equipment requirements, and operation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

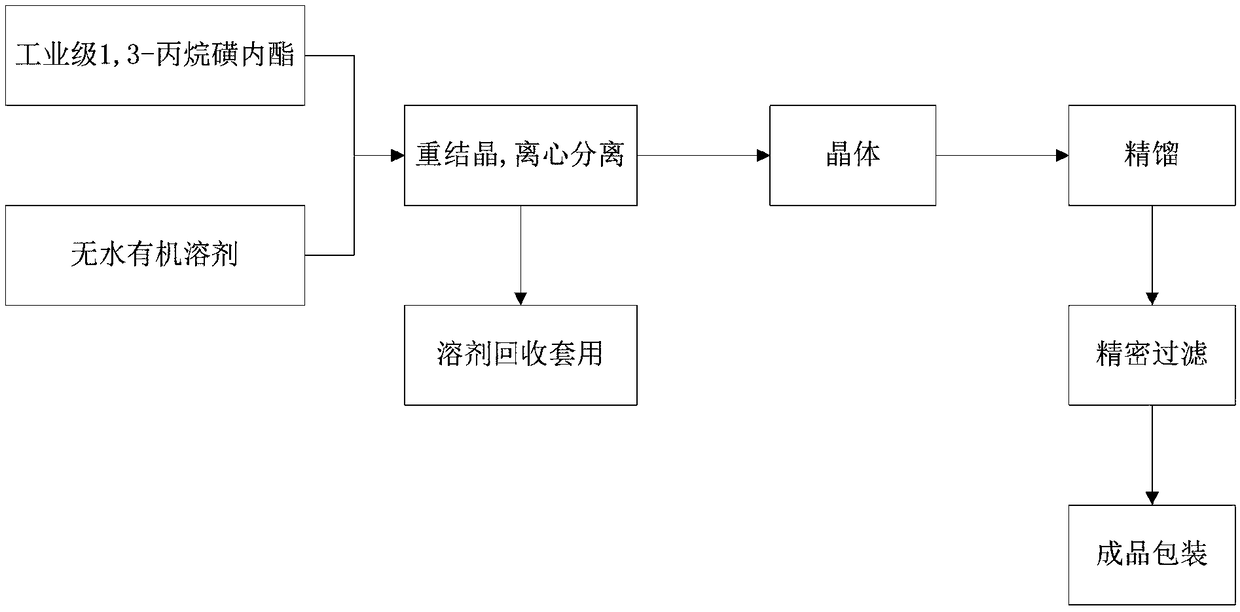

[0023] This example provides a preparation method of electronic grade 1,3-propane sultone, comprising the following steps: after recrystallizing industrial grade 1,3-propane sultone with anhydrous organic solvent, separating the crystal, The crystal is rectified, and the water and impurities are separated under the state of total reflux to obtain electronic grade 1,3-propane sultone.

[0024] In some preferred embodiments, the recrystallization specifically adopts the following method: add industrial grade 1,3-propane sultone to an enamel reactor with frequency conversion and speed regulation mechanical stirring, and raise the temperature of the reactor to 40-45°C , then drop anhydrous organic solvent into the reaction kettle to dissolve 1,3-propane sultone, keep stirring for 50 to 70 minutes, slow down the stirring speed of the mixed solution, and slowly lower the temperature of the mixed solution, and after the crystals are precipitated, the The solution was centrifuged, and...

Embodiment 1

[0035] Embodiment 1 of the present invention provides a preparation method of electronic grade 1,3-propane sultone, comprising the following steps:

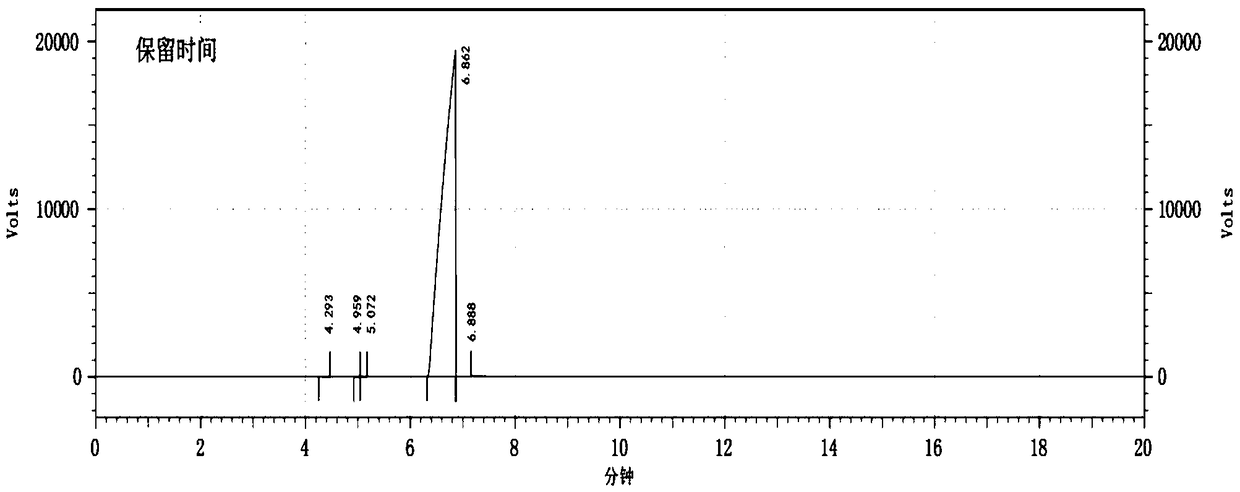

[0036] (1) After adding 300kg of industrial grade 1,3-propane sultone to a 500L enamel reactor with frequency conversion speed regulation mechanical stirring, the temperature of the reactor was raised to 40°C, and then 100kg of Water ethanol, at a stirring speed of 80r / min, after insulated and stirring for 60min, the stirring speed was reduced to 25r / min, and the temperature of the mixed solution was slowly lowered at a cooling speed of 3°C / h until crystals were precipitated. Centrifugal separation, the solvent recovery sleeve is used for the next batch;

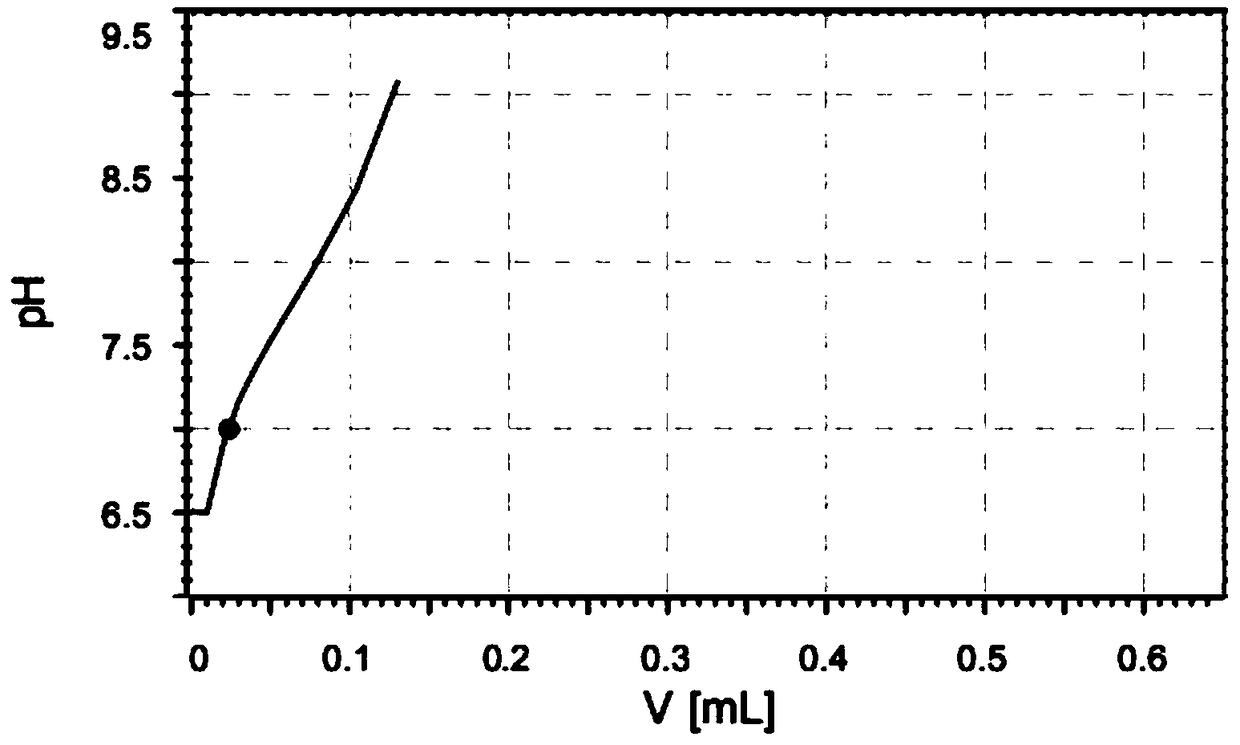

[0037] (2) Add the crystals obtained by centrifugation in step (1) into a 200L rectification kettle, heat the temperature in the rectification kettle to 100°C with an electric heating oil bath, and turn on the vacuum unit to reduce the vacuum in the rectification kettle to 100°...

Embodiment 2

[0044] Embodiment 2 of the present invention provides a preparation method of electronic grade 1,3-propane sultone, comprising the following steps:

[0045](1) After adding 250kg of industrial-grade 1,3-propane sultone into a 500L enamel reactor with frequency conversion speed regulating mechanical stirring, the temperature of the reactor was raised to 40°C, and then 100kg of For water methanol, the stirring speed is 85r / min, after 60min of heat preservation and stirring, the stirring speed is reduced to 20r / min, and the temperature of the mixed solution is slowly lowered at a cooling speed of 2°C / h until the crystals are precipitated. Centrifugal separation, the solvent recovery sleeve is used for the next batch;

[0046] (2) Add the crystals obtained by centrifugation in step (1) into a 200L rectification kettle, heat the temperature in the rectification kettle to 110°C with electric heating in an oil bath, and turn on the vacuum unit to reduce the vacuum in the rectificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com